Digital control working machine with grinder

A grinding device and processing machine technology, applied in metal processing machinery parts, feeding devices, metal processing and other directions, can solve the problems of lower product qualification rate, prolonged processing time, inconsistent product specifications, etc., to reduce inertial force and improve followability , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

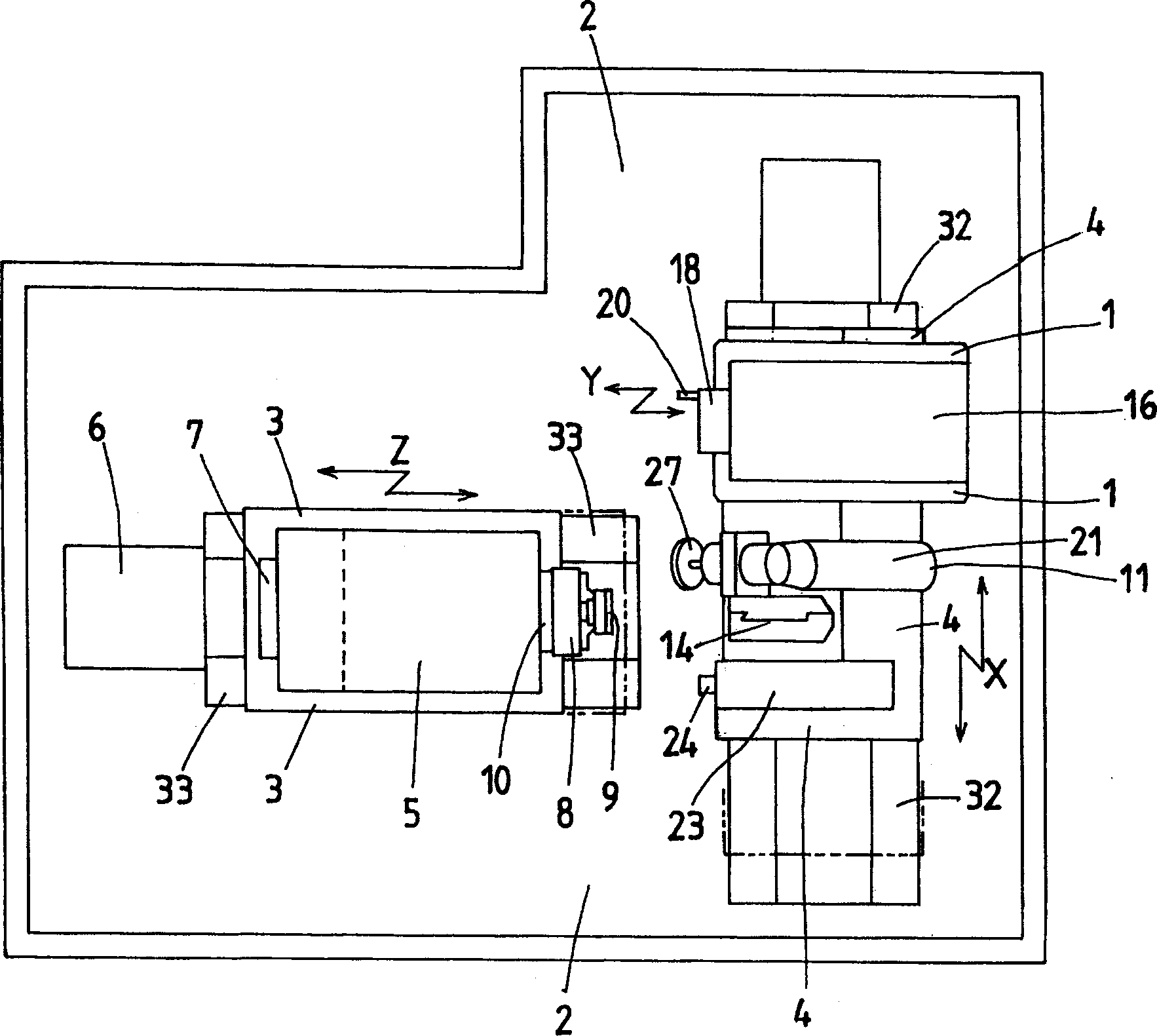

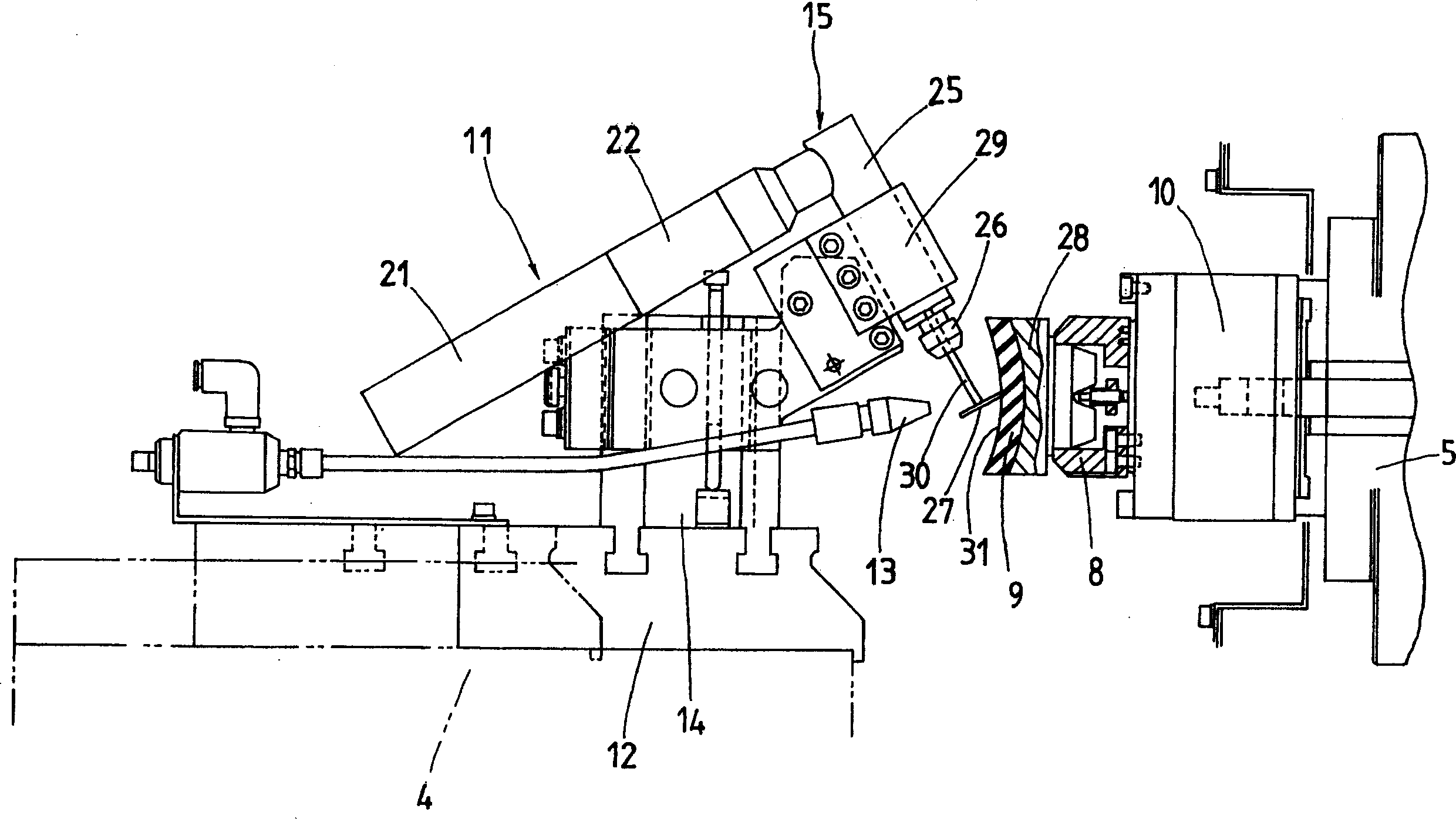

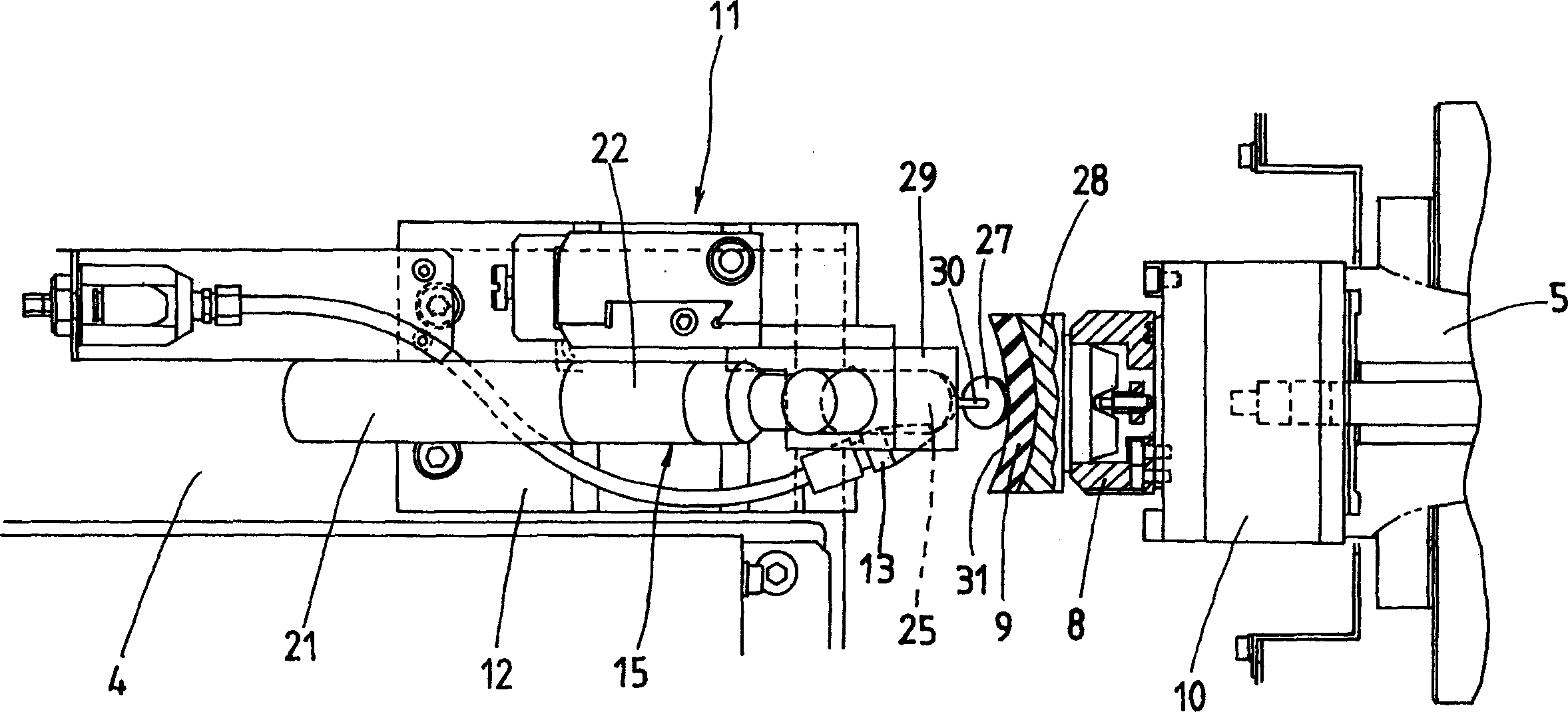

[0031] Hereinafter, an embodiment of a numerical control (NC) processing machine with a grinding device according to the present invention will be described with reference to the drawings. In addition, the NC processing machine with a grinding device according to the present invention is compatible with Figure 4 Compared with the NC processing machine shown, since the main shaft, the Z-axis table that can move in the Z-axis direction, and the X-axis table that can move in the X-axis direction correspond to each other, the same numbers are used for these parts Be explained.

[0032] Such an NC processing machine with a grinding device, for example, includes: a Z-axis table 3, on a Z-axis base 33 provided on the base 2 of the processing machine, which can move along the Z-axis direction as the longitudinal direction of the spindle 10; and X The axis worktable 4 is provided separately from the Z axis worktable 3, and can move along the X axis direction perpendicular to the Z axis on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com