Method for producnig non-inflation tyre and non-inflation tyre

A technology of a pneumatic-free tire and a manufacturing method, which is applied in the directions of wheels, highly elastic wheels, transportation and packaging, etc., can solve the problems of short service life, dangerous use, poor reliability, etc., and achieves good elasticity and friction effect. the effect of increasing safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Detailed description of the preferred embodiment:

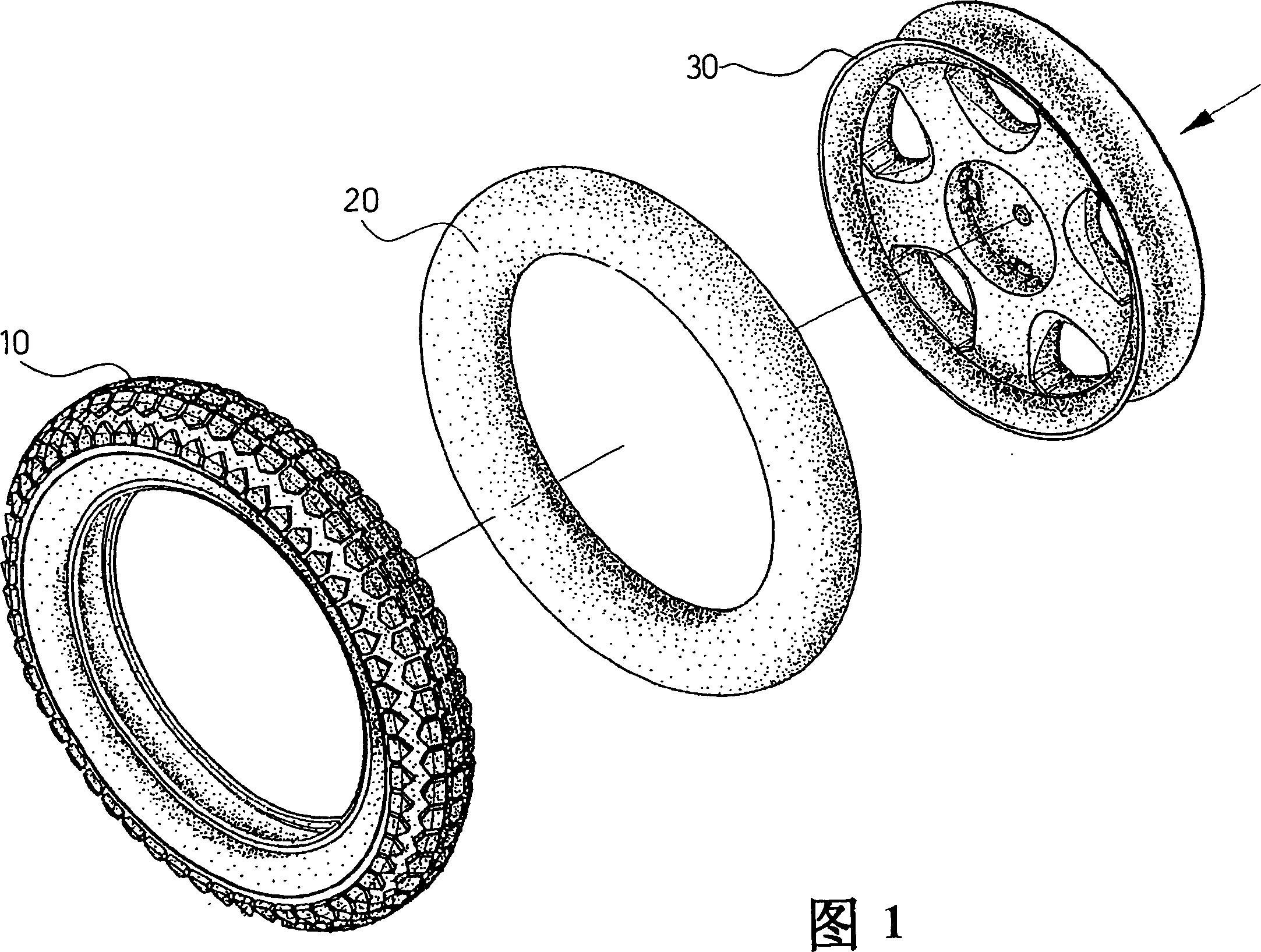

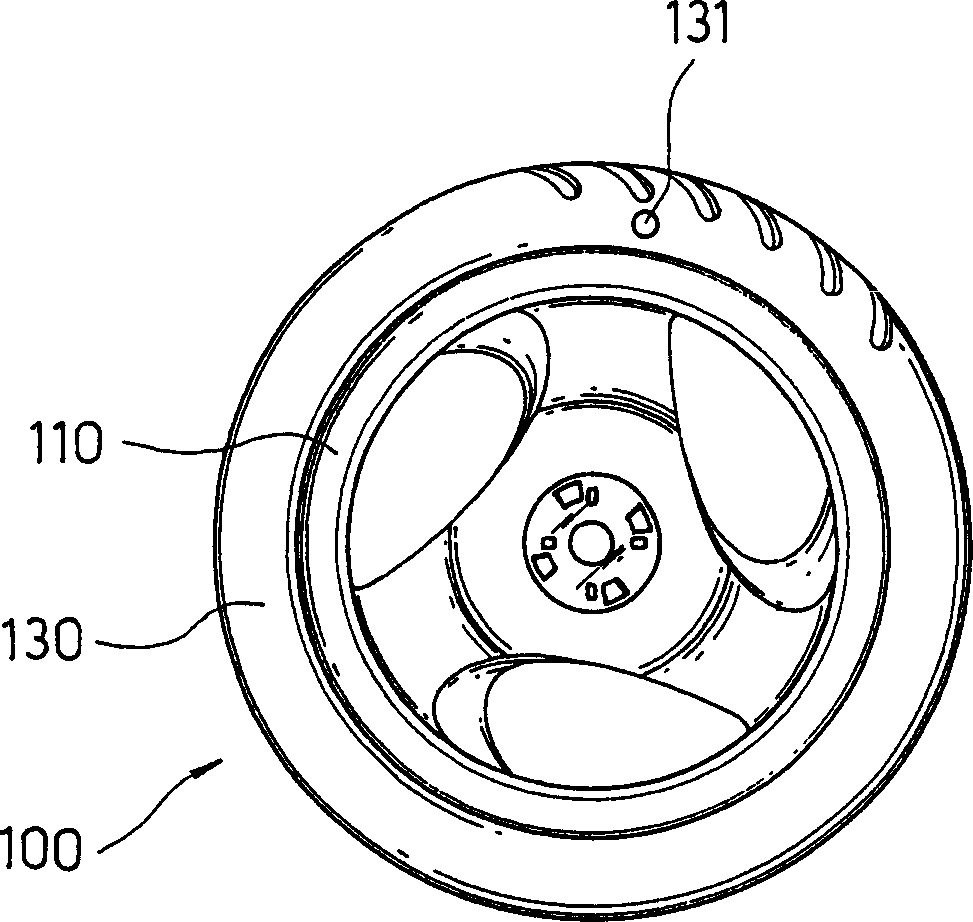

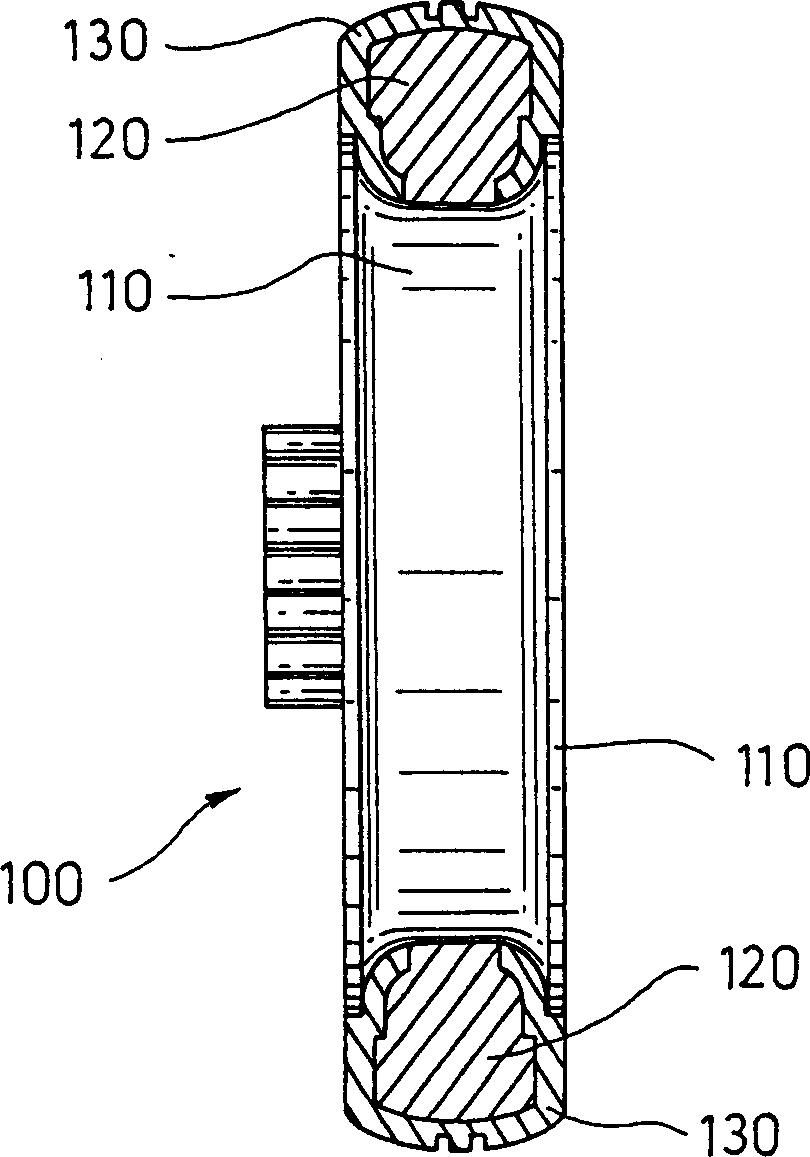

[0017] See figure 2 versus image 3 , Which are respectively a front view and a cross-sectional view of the pneumatic tire 100 according to the present invention. Such as image 3 As shown, the pneumatic tire 100 according to the present invention includes: a tire inner frame 110; a carcass film 130; and an inner tube layer 120. Such as figure 2 As shown, the side surface of the carcass film 130 has at least one pouring hole 131 for pouring the foam material forming the inner carcass layer 120. The number of injection holes 131 can be increased or decreased depending on the material of the inner tube layer 120. More than one perfusion hole 131 is evenly distributed on the side surface of the tyre membrane 130.

[0018] The tire inner frame 110 is made of a material with higher hardness, and the material of the tire inner frame 110 may be metal or plastic with higher hardness. The outer side of the carcass film 130 has th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com