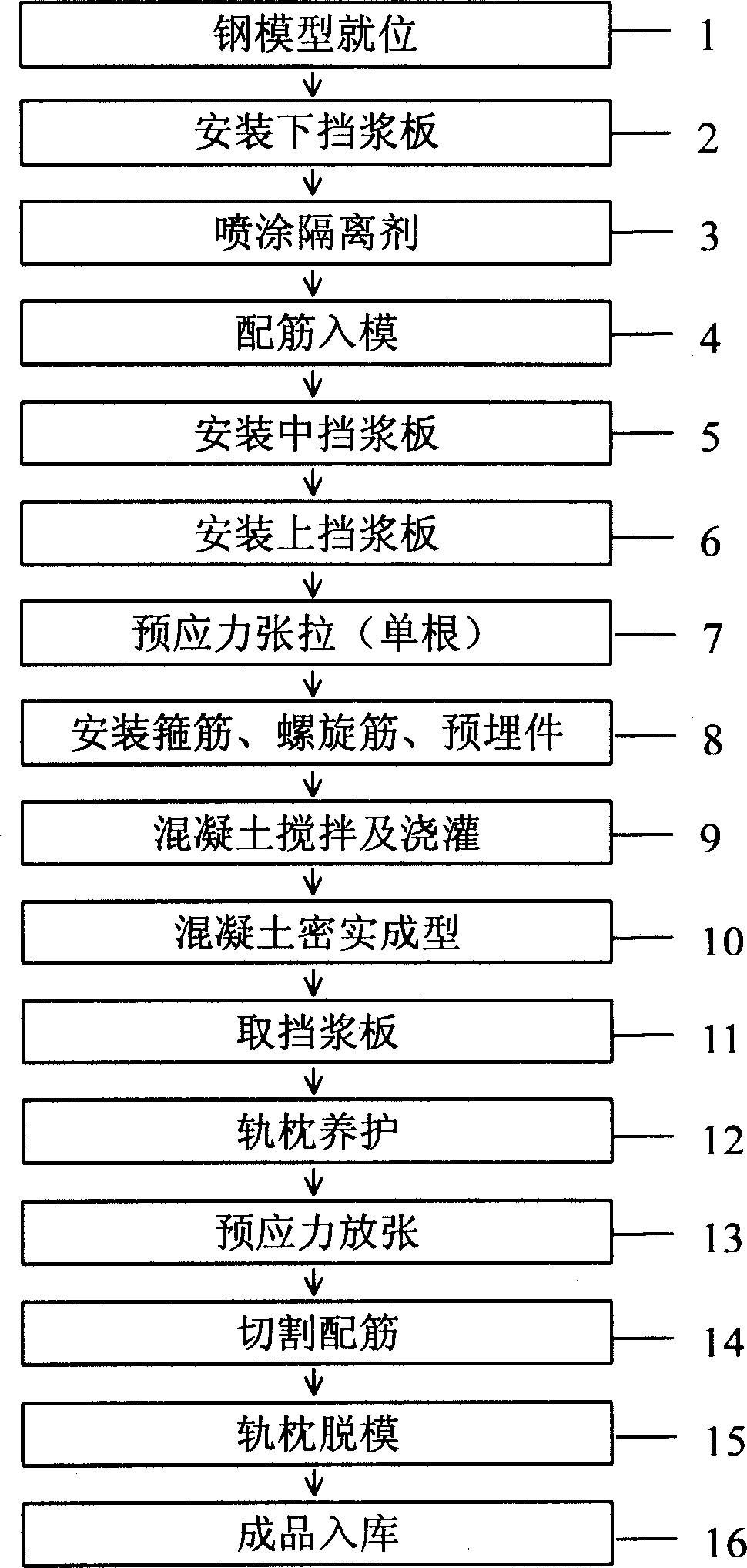

Prestressed concrete rail sleeper production process using long line pedestal method

A production process and prestressing technology, used in manufacturing tools, ceramic molding machines, etc., can solve the problems of unstable mechanical properties of sleepers, affecting sleeper quality, and high comprehensive energy consumption, reducing procurement costs, reducing investment, and one-time use. The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation plan

[0032] As shown in the accompanying drawings, the production process of the present invention, firstly, the sleeper steel model is in place, the 4 × 1 steel model is vertically arranged on the pedestal bracket, and the steel molds are connected by hinges; enter the process 2, install the lower baffle support On the hinged connection positioning block between the steel molds; enter process 3, spray the spacer evenly in the model shell; enter the reinforcement mold entry process 4, penetrate the prestressed reinforcement into the positioning plate and arrange it into the mold; enter process 5, Install the middle baffle, and insert the reinforcing bars into the baffle according to the order of the reinforcement position; enter the process 6 to install the upper baffle; the prestressed tensioning process 7 is to use a 10t jack to tension the prestressed reinforcement one by one, And anchored on the anchor plate as a whole, the anchor plate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com