Processing method of lighter electronic striking head and its special mould

A processing method and lighter technology, applied in the direction of combustion method, combustion ignition, lighting and heating equipment, etc., can solve the problems of low production efficiency, high scrap rate, troublesome head-shot processing, etc., achieve high production efficiency, control production cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

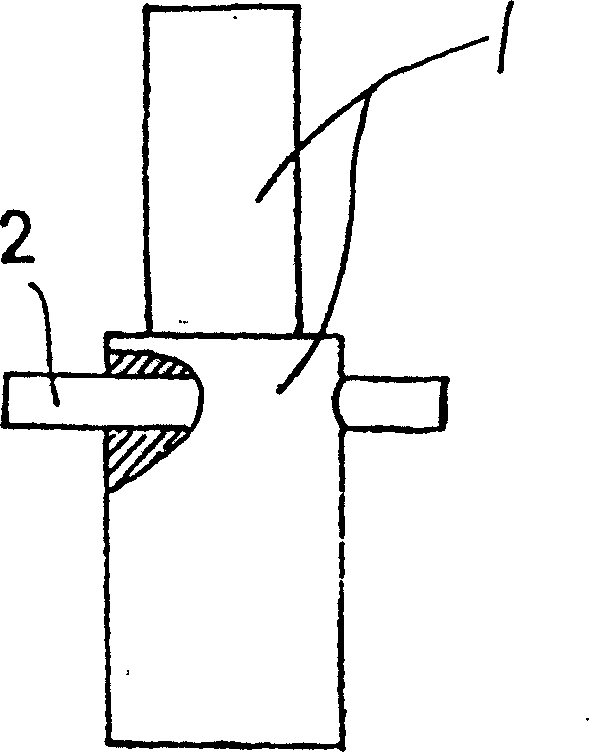

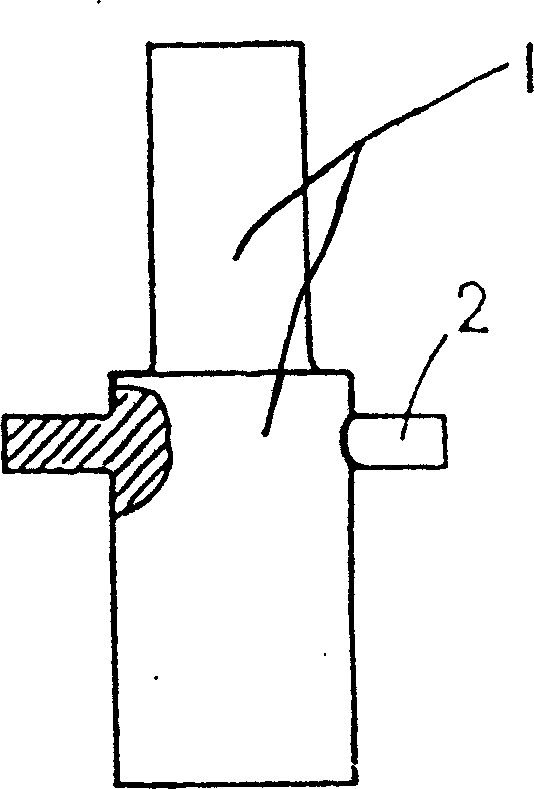

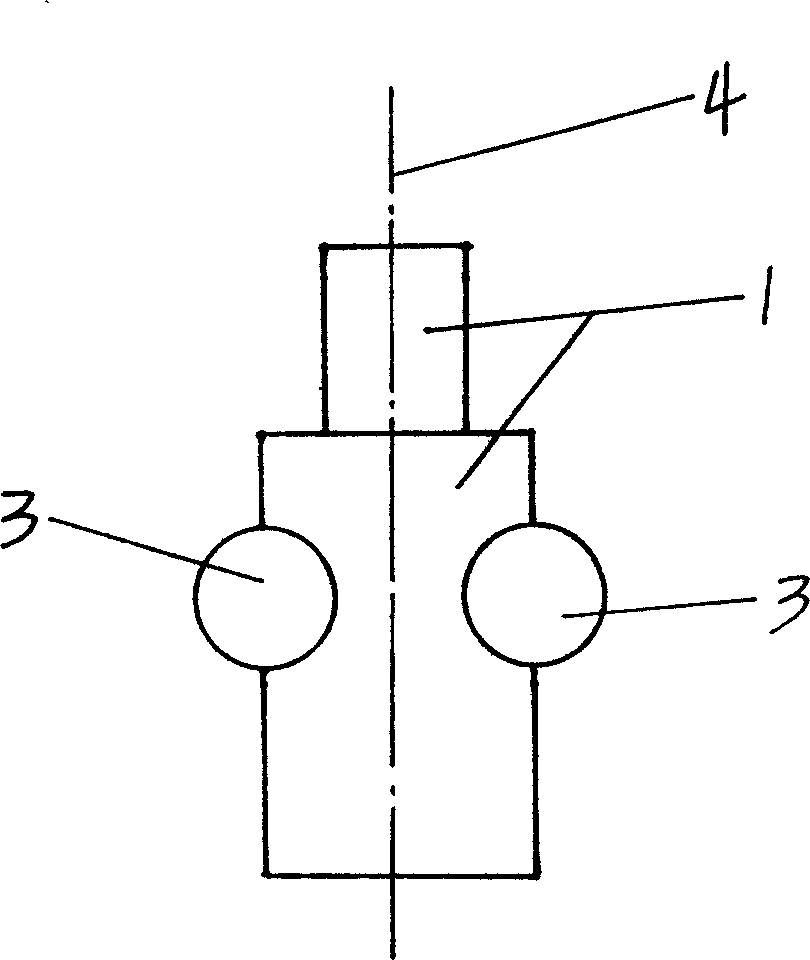

[0018] In each drawing: 1. Step shaft; 2. Guide shaft; 3. Flat lug; 4. Step shaft axis; 5. Left half mold; 6. Right half mold; 7. Limiting insert; 8. Half cylinder hole Groove; 9, punching flat shaft; 10, mating surface; 11, limit groove; 12, punching head perforation.

[0019] Such as image 3 , Figure 4 , Figure 5 As shown, in order to overcome the disadvantage that the processing guide shaft of the mold is easily damaged when cold extrusion processing the electronic head of the lighter in the past, in the process of processing, the guide shaft 2 of the electronic head of the lighter is partially punched and flattened as shown image 3 , Figure 4 state, forming two symmetrical flat ears 3, a part of each flat ear 3 is located on the inner side of the cylindrical surface of the cylindrical blank, and the other part is located on the outer side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com