Single mode optical fibre

A single-mode fiber, fiber technology, applied in clad fibers, multi-layer core/clad fibers, optics, etc., can solve the problems of limiting four-wave mixing nonlinear dispersion, low total waveguide dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

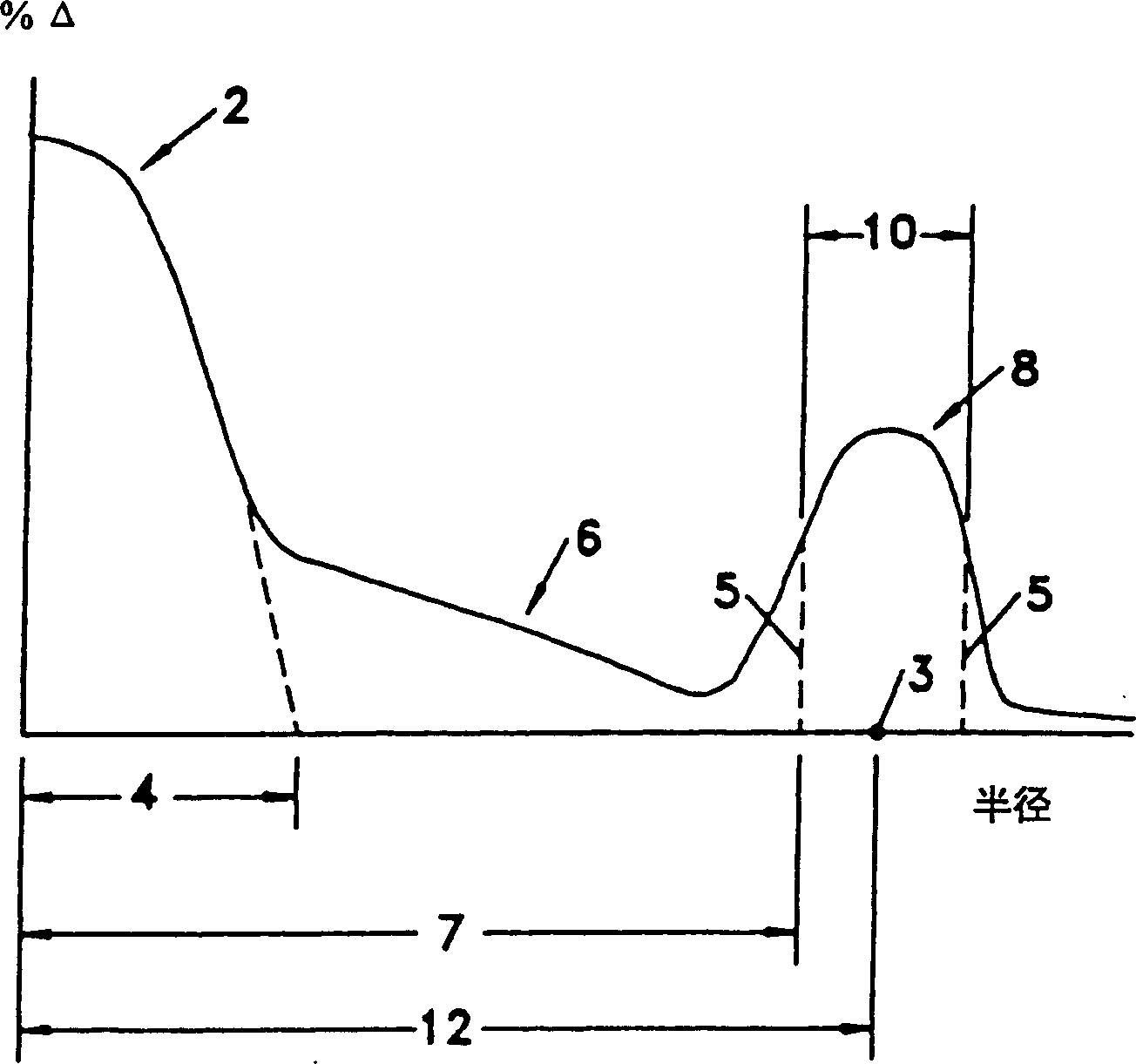

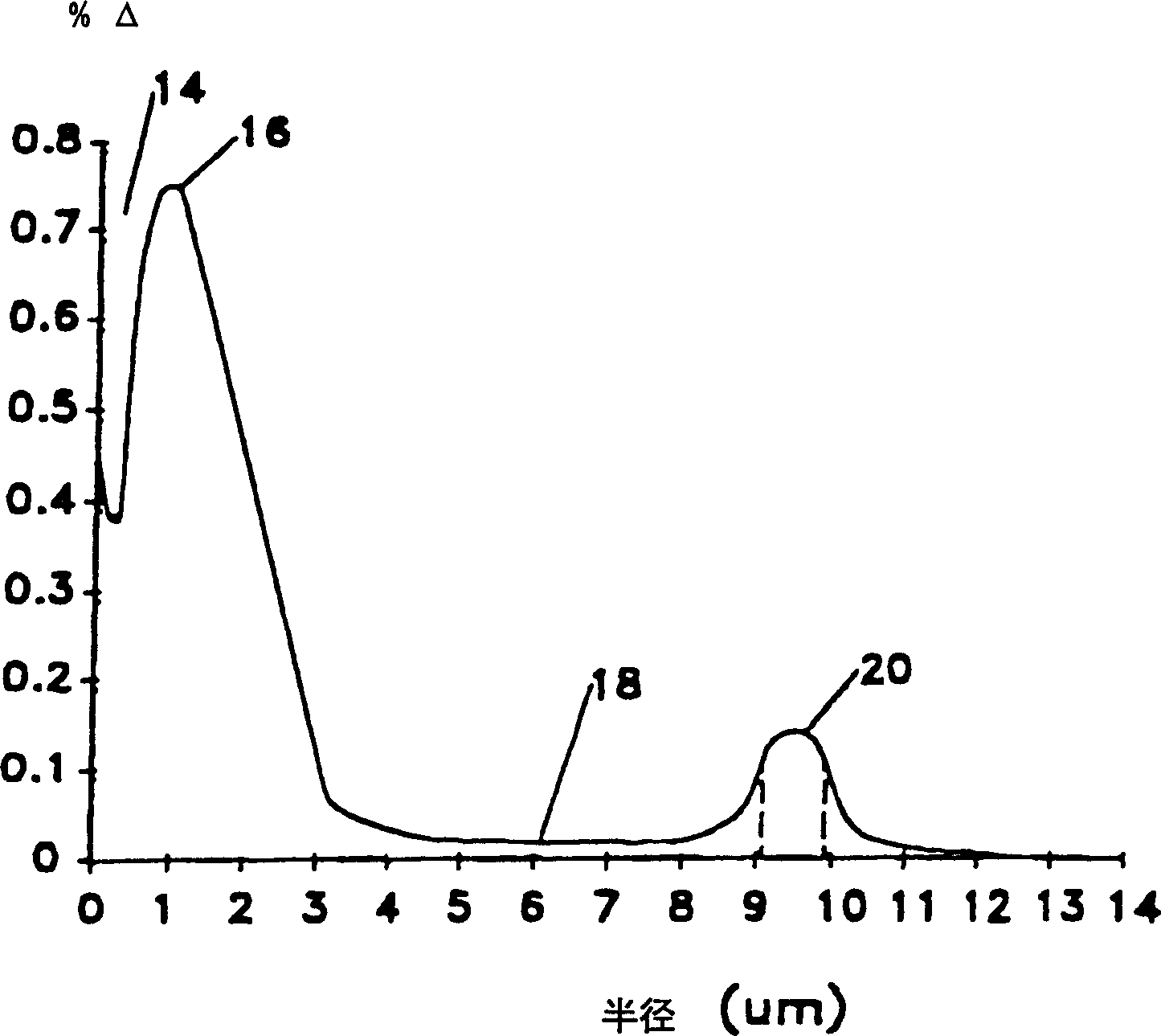

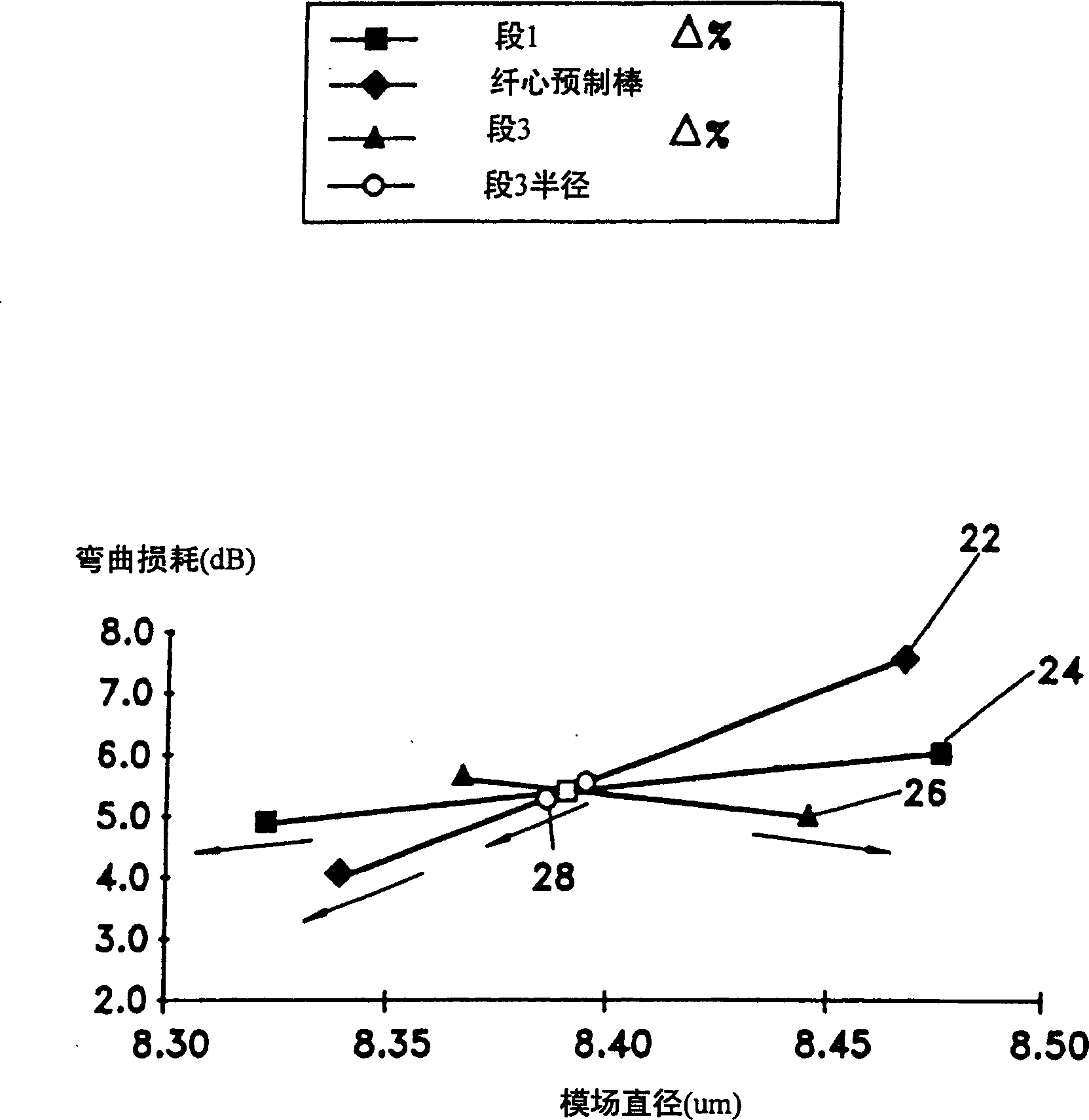

[0073] The novel optical fiber described here includes a core region with three segments. These segments are distinguished from each other by the refractive index profile characteristics of a given segment. The three-segment core region provides sufficient flexibility for fiber design to accommodate a wide range of functional requirements. Parameters that can be varied to provide specific fiber performance are:

[0074] Δ% for each of the three domains;

[0075] the radius of each of the three regions; and

[0076] The shape of the refractive index profile for each of the three regions.

[0077] The properties of the novel fiber described here are: positive total dispersion in the specified wavelength range of 1530nm to 1570nm to counteract the non-linear effect of SPM; very low dispersion slope in the specified wavelength range to facilitate WDM operation ; and zero dispersion outside the specified wavelength to limit dispersion due to four-wave mixing. Positive dispersi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com