Fixed constant-velocity universal joint body and its manufacturing method

A constant-velocity universal joint with uniform circumferential distribution technology, which is applied to rotating parts that resist centrifugal force, elastic couplings, mechanical equipment, etc. It can solve the problems of reduced assembly and difficulty in pushing the inner ring of the joint, and achieves simplified assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

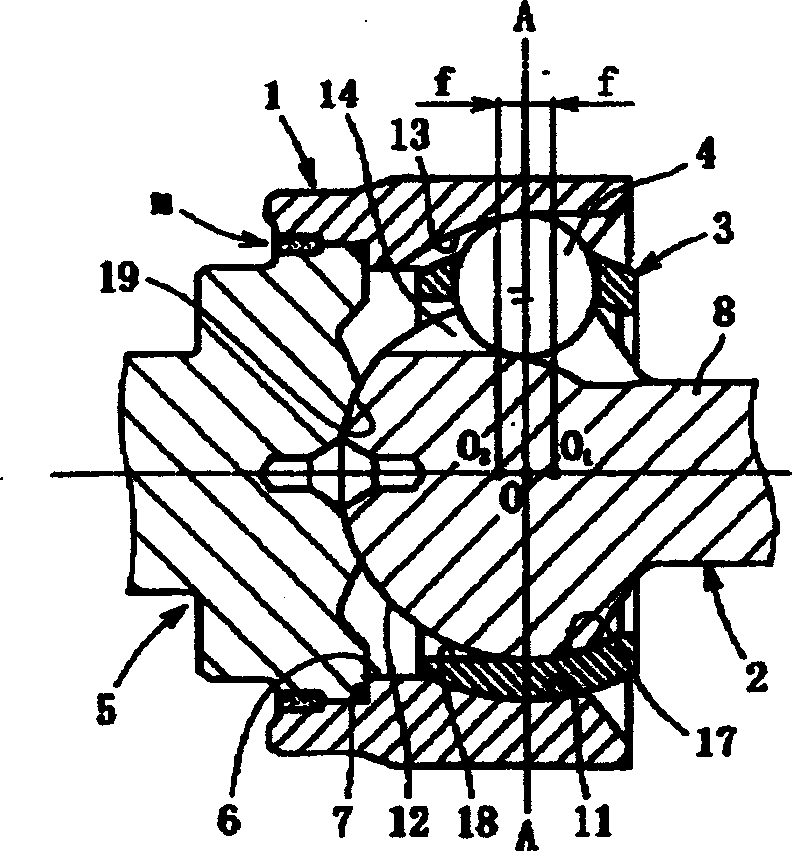

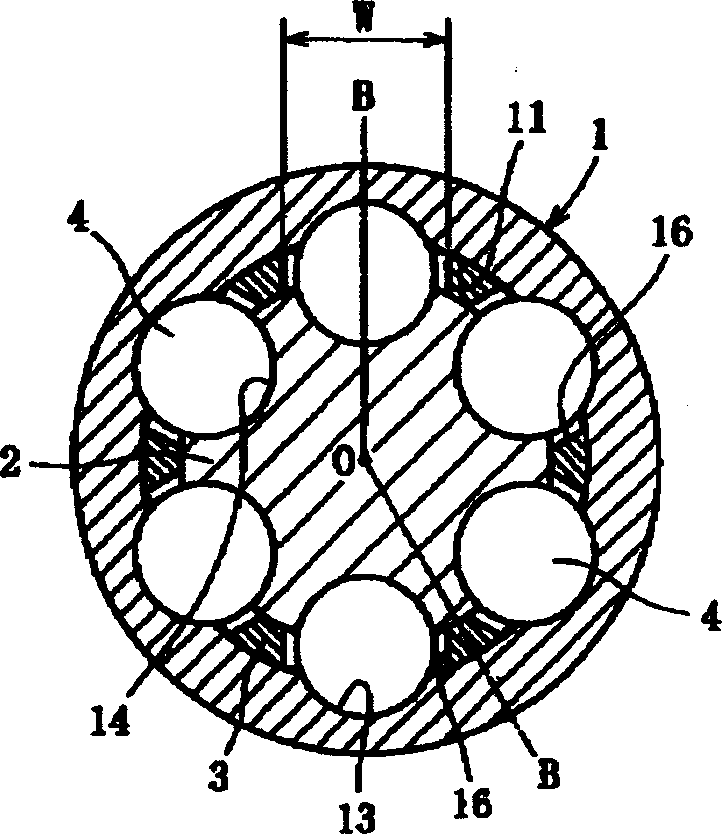

[0039] Figure 1 (a) and Figure 1 (b) show an embodiment of the present invention, which is a UJ-type fixed constant velocity universal joint, where Figure (a) is taken along the line BOB in Figure (b) Open sectional view, Figure (b) is a sectional view taken along the AOA line in Figure (a). The fixed type constant velocity universal joint in this embodiment includes a joint outer ring 1, a joint inner ring 2, a retainer 3, a torque transmission ball 4 (hereinafter referred to as a ball), and a shaft 5.

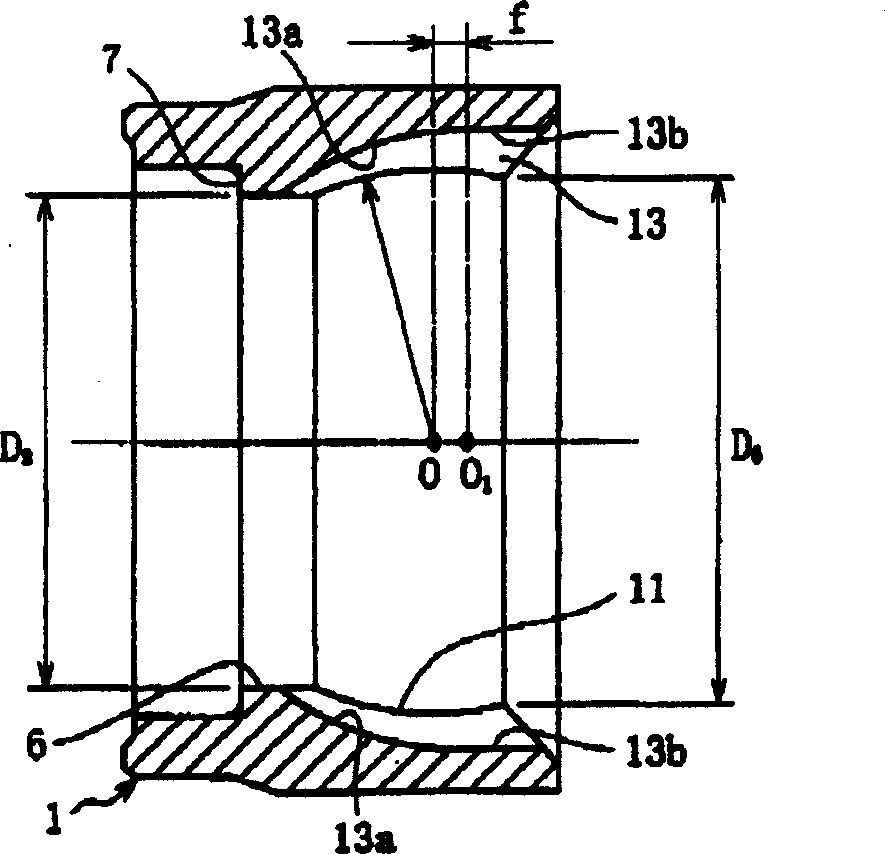

[0040] Such as figure 2 As shown, the joint outer ring 1 is in the shape of a sleeve, one end of which is open for inserting the shaft 5, and the other end is open for receiving the joint inner ring 2, the retainer 3 and the ball 4. One end surface (rod side) of the outer ring 1 of the joint is formed by the inner cylindrical surface 6, and the smallest inner diameter D of the inner cylindrical surface 2 Greater than the outer diameter D of the inner ring 2 of the joint 1 , In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com