Sequentially joined-segment armature and ac machine using same

A technology for AC motors and armatures, applied in the direction of synchronous generators, the shape/style/structure of winding conductors, etc., which can solve the problems of increasing the length of rotating motors, increasing the difficulty of stator coils, and large spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

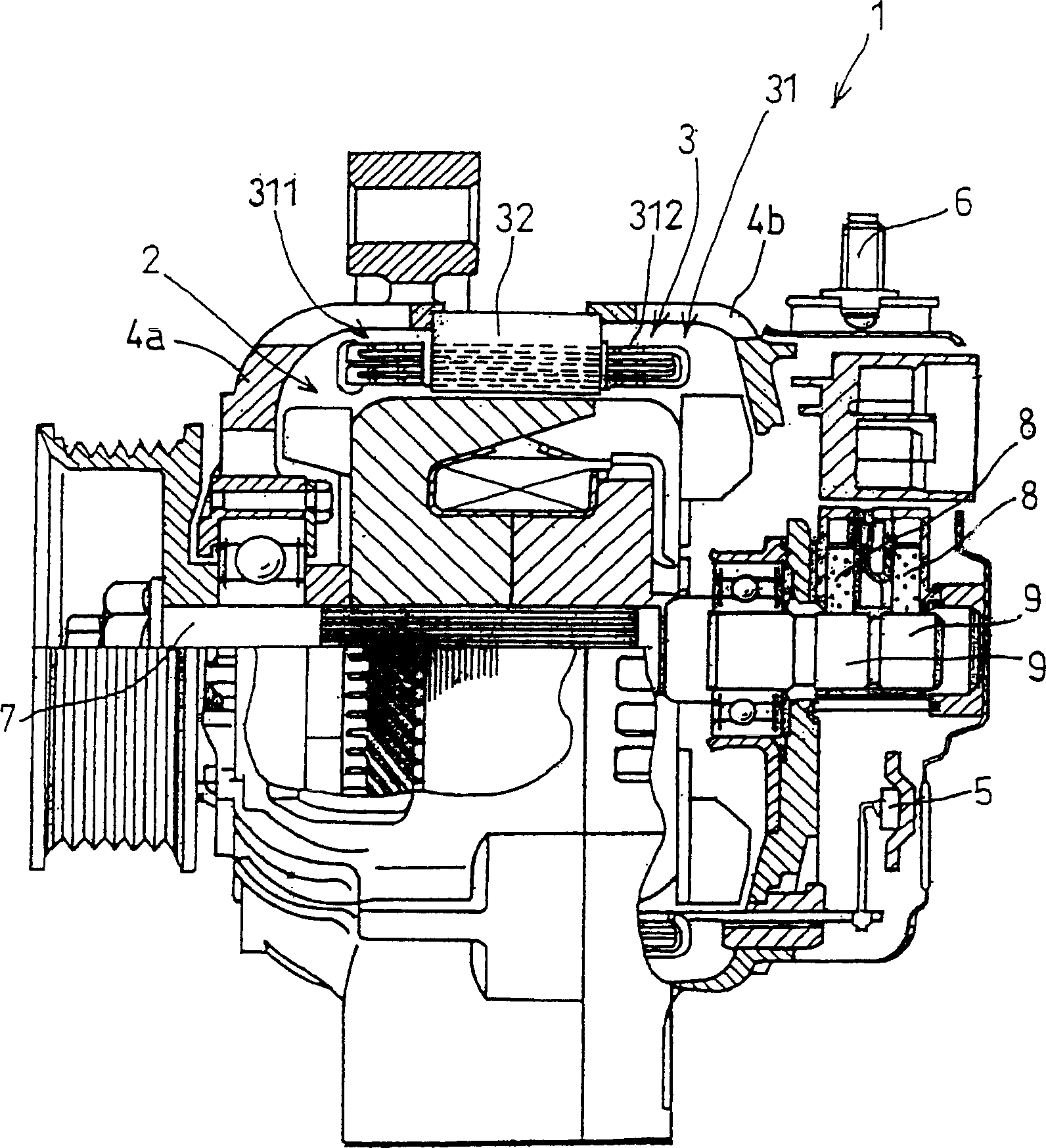

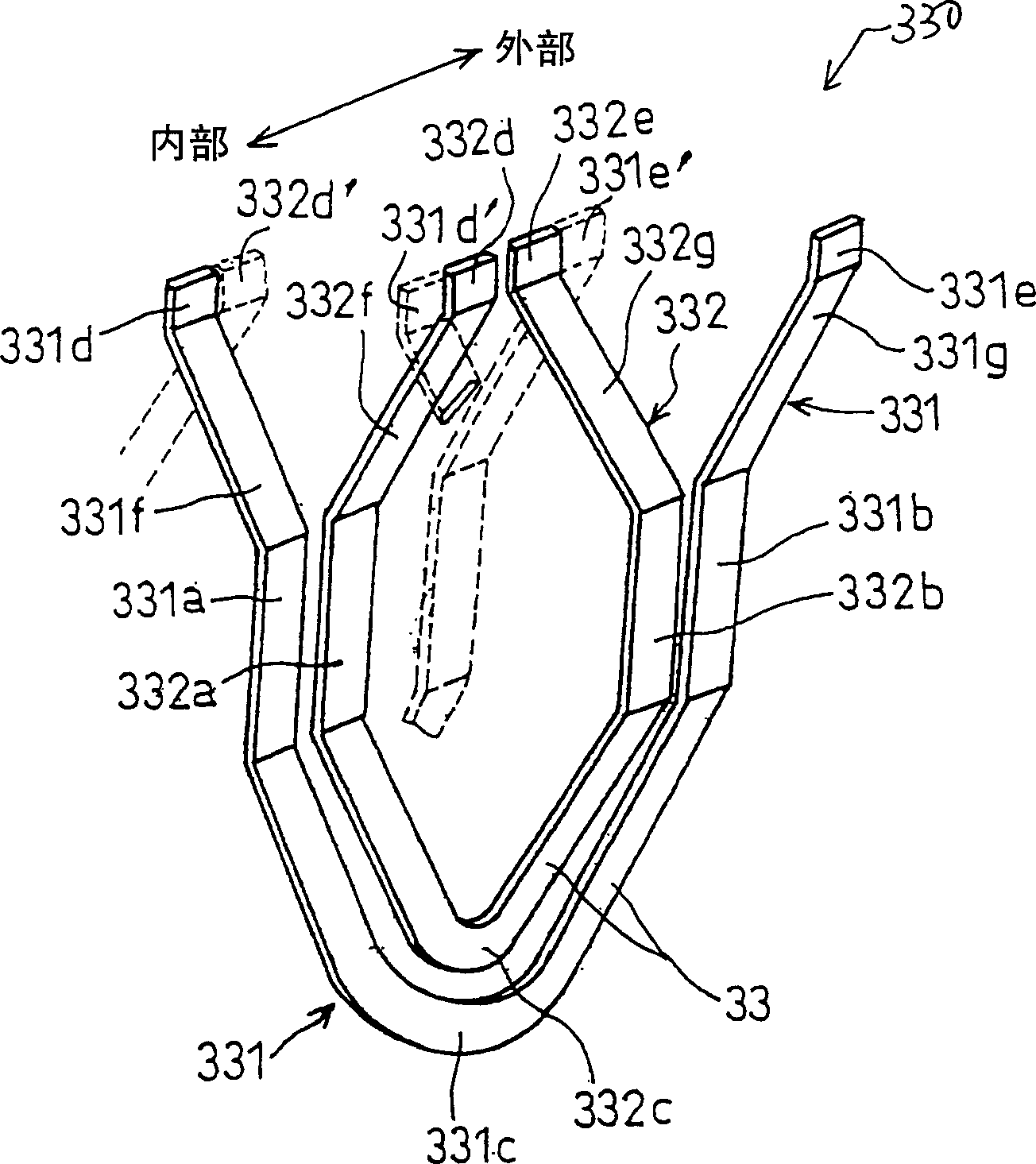

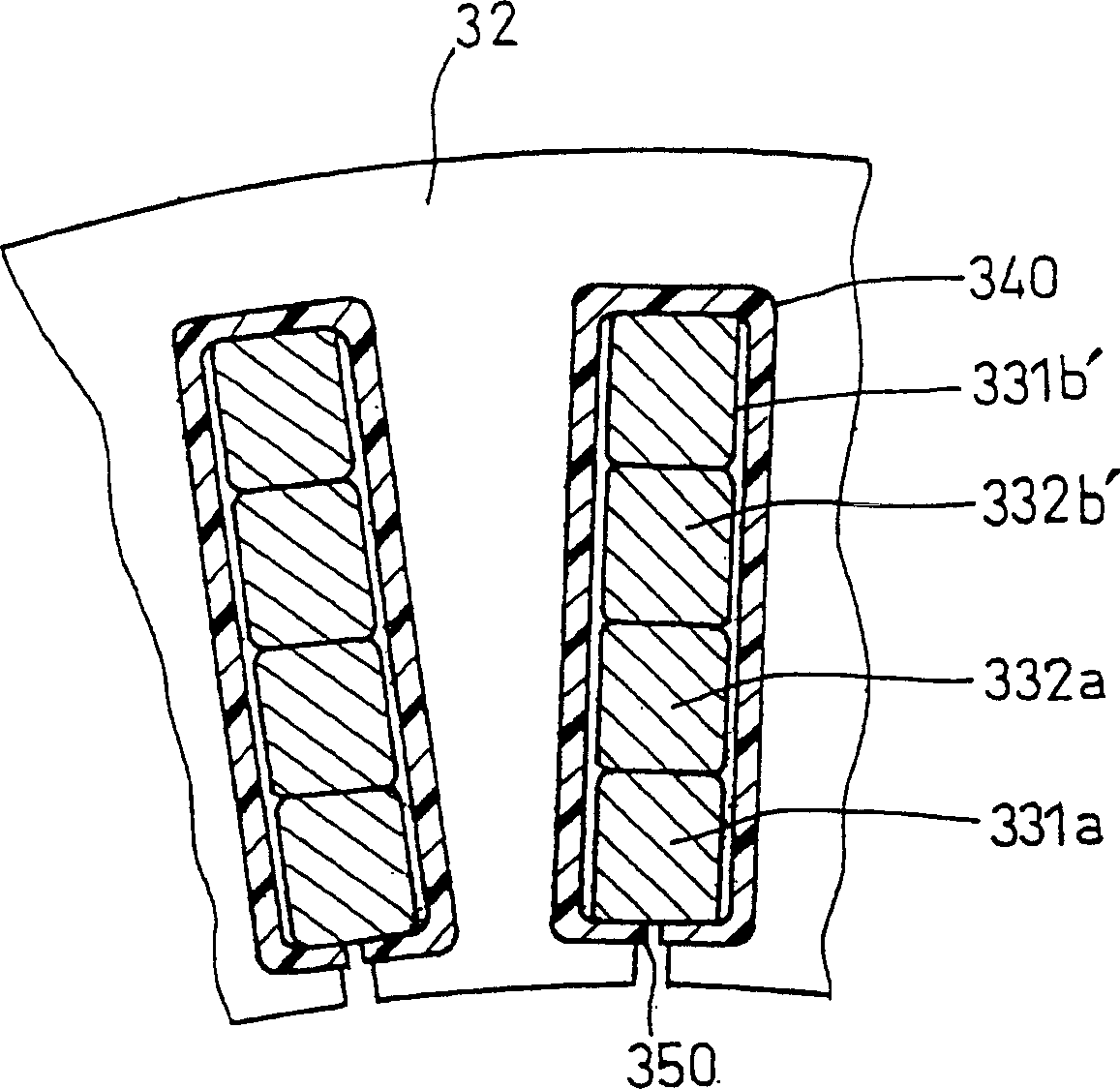

[0127] Figure 12 is a longitudinal sectional view of a 16-pole stator 3 (ie armature winding) substantially composed of a stator core 32 and a stator coil 31, Figure 13 It is a back view of the stator 3 , and the stator core 32 includes electromagnetic steel sheets of lamination structure. Like the first embodiment, the stator coil 31 includes a three-phase winding by being wound in slots formed in the stator core 32 using insulating sheets.

[0128]An input / output wire set 233 composed of terminal lead wires 33U, 33V, and 33W extends rearward from the first coil end 312 of the stator coil 31 . exist Figure 12 and 13 As clearly seen in , the electrical connection between the stator coil 31 and the inverter (not shown) is achieved by connecting the bent contacts 3300 fixed to the terminal leads 33U, 33V and 33W to the metal connector 13b on the terminal block 13 .

[0129] The neutral point 33N and the neutral point connecting lead wires 33U', 33V' and 33W' extending fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com