Stacker for plate members, method for stacking plate members, and stacked plate members

A technology for stacking machines and panels, which is applied in the field of stacking machines, and can solve problems such as easy deformation of inner heat sinks, difficulty in placement, deformation of inner heat sinks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The best way to practice the invention

[0044] The present invention will be described below with reference to the accompanying drawings.

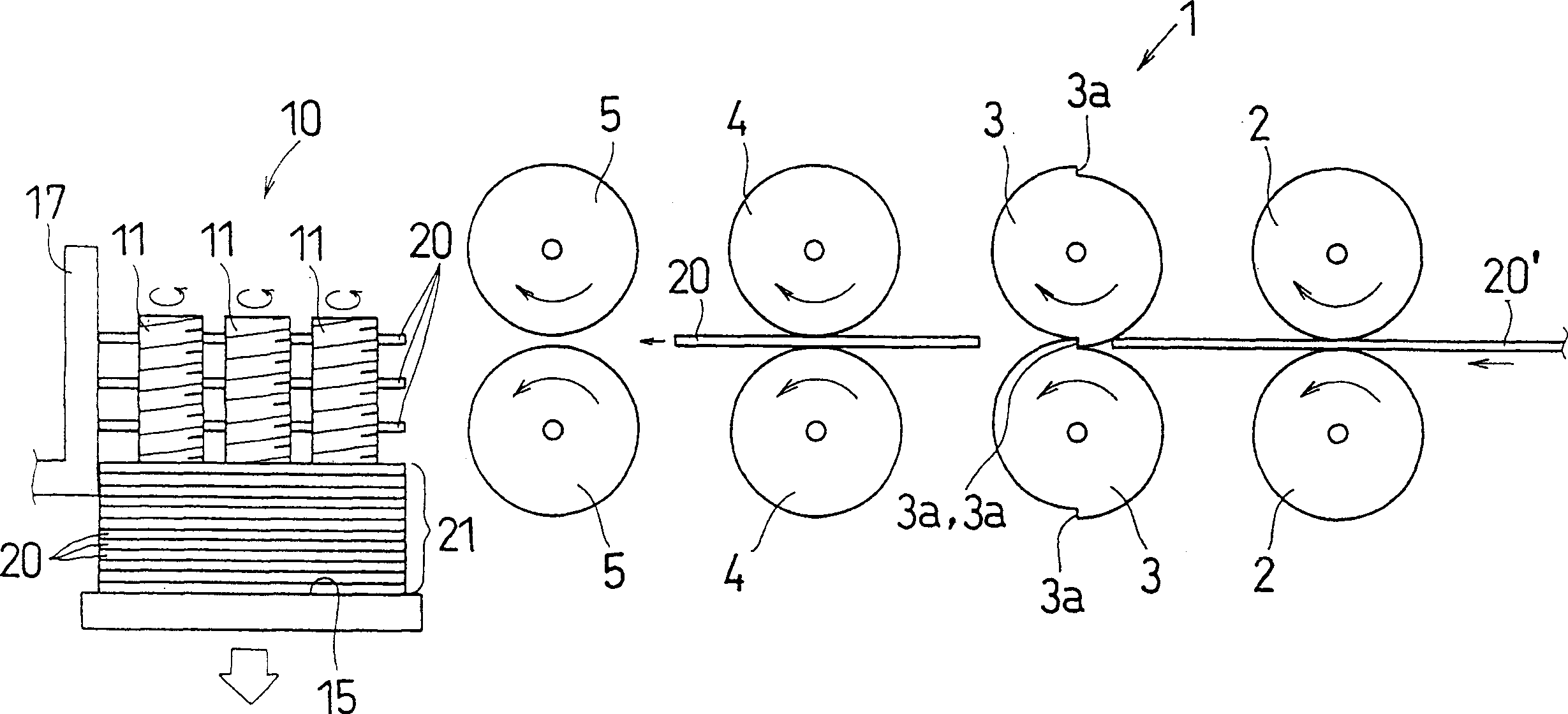

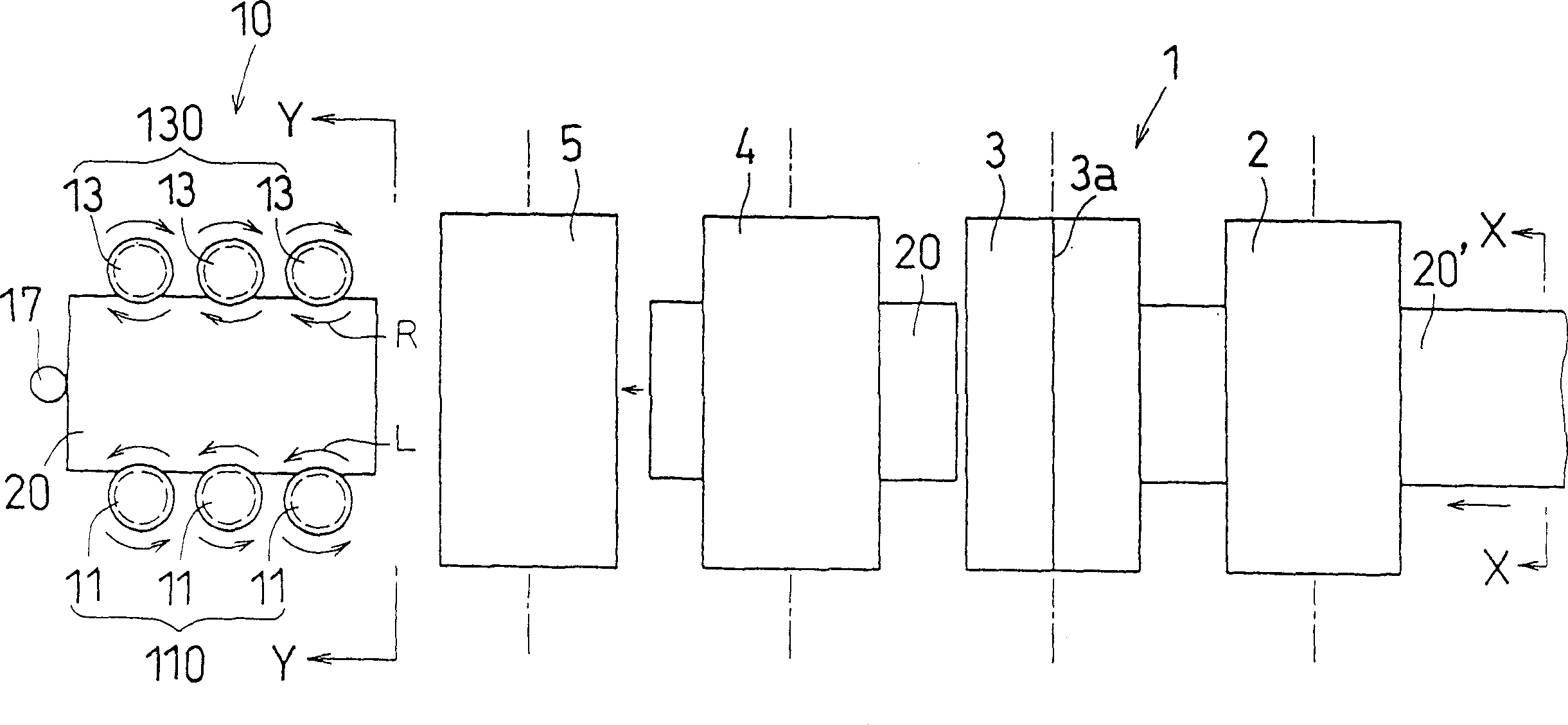

[0045] Figure 1-2 and 3-5 denote a stacker for stacking panels according to an embodiment of the present invention. exist figure 1 and 2 Among them, reference numerals 1 and 10 denote a clipper and a stacker, respectively.

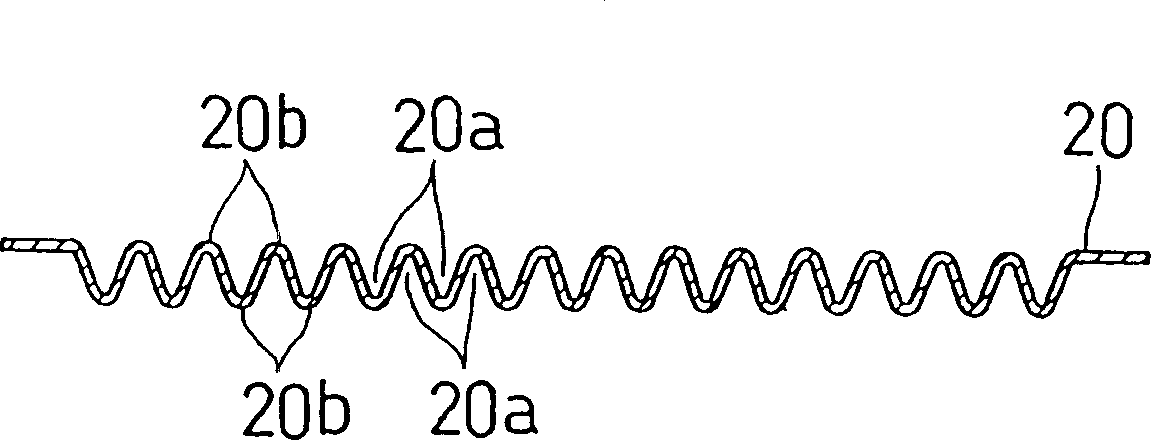

[0046]In this embodiment, the plate 20 to be stacked by the stacker 10 is a metal piece cut by the flying shear 1, or a corrugated inner fin made of aluminum or an aluminum alloy. The inner fin 20 is a member to be provided in a heat exchange tube constituting a heat exchanger such as an evaporator for a vehicle air conditioner. Typically, such inner fins 20 have a length of 150-250 mm and a width of 20-70 mm. Its thickness is particularly small, for example 0.15 mm or less.

[0047] Such as figure 1 and 2 As shown in , the flying shear machine 1 is a kind of long plate member (that is, the inner heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com