Vaporizing cracking device for alcohol fuel using waste heat of automobile silencer

A technology for automobile muffler and cracking device, which is applied in the direction of muffler, exhaust device, machine/engine, etc. It can solve the problems of interrupting the gasification and cracking reaction of alcohol fuel and the agglomeration of catalytic particles, and achieves simple and practical structure and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

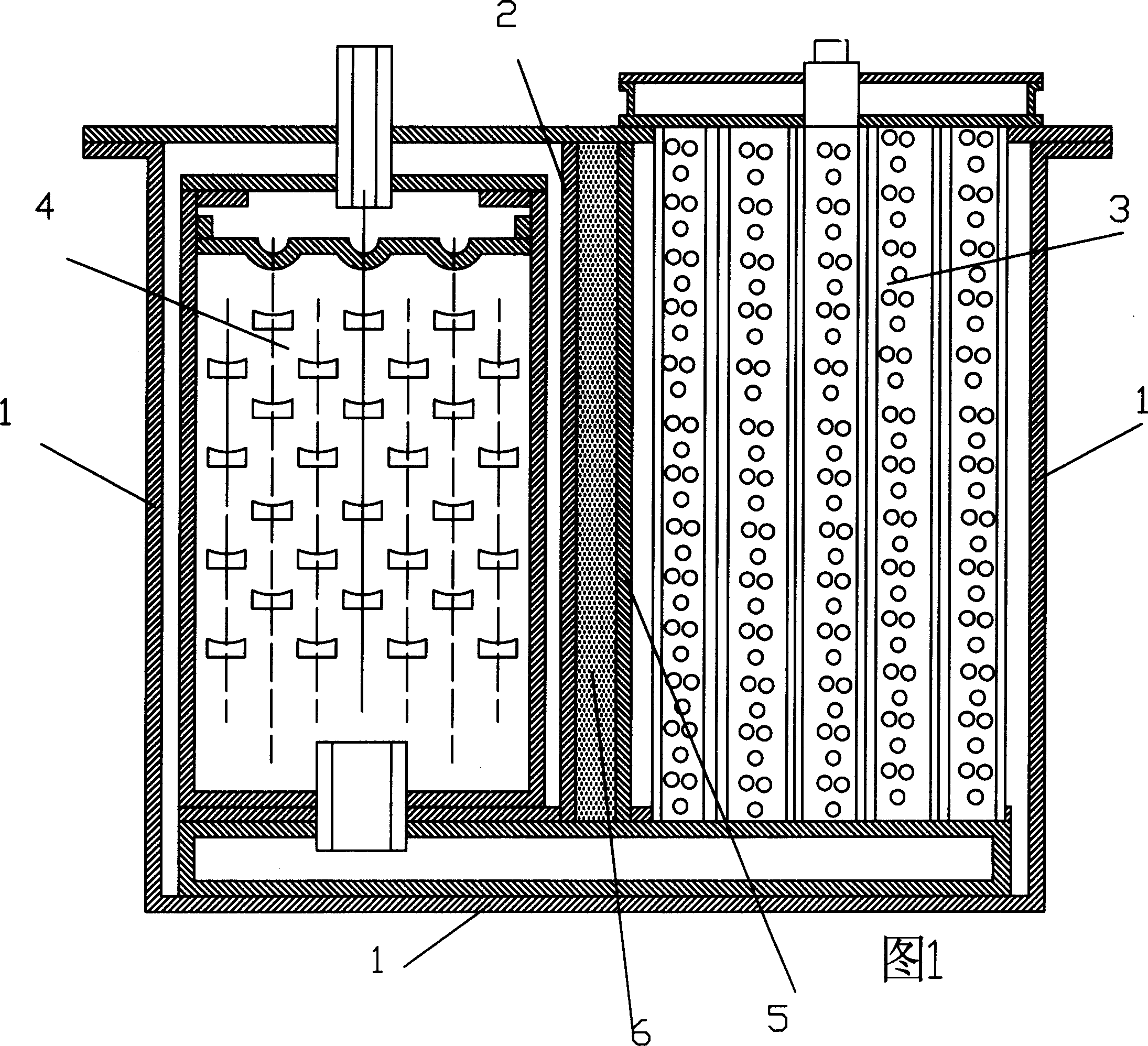

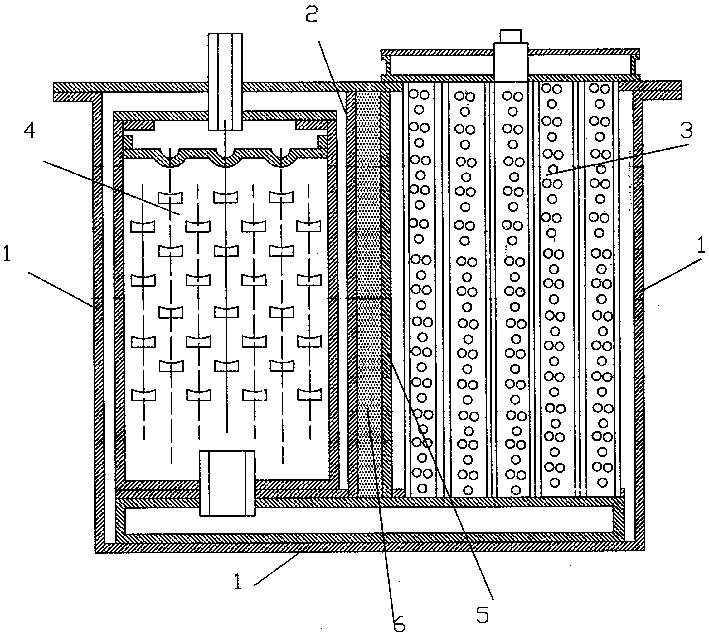

[0007] As shown in Figure 1, a dividing plate 2 is provided in the middle of the case shell 1 of the present invention, and it is divided into two chambers by the case shell, namely the catalytic cracking reaction chamber 3 and the evaporation chamber 4, further designed to increase the size of the spacer on one side of the dividing plate 2. A partition 5, the distance between the two partitions 2 and 5 is ≥ 8mm, and the space between the two partitions 2 and 5 is filled with high temperature resistant material 6. Catalysts are installed in the reaction tubes, and the reaction tubes are vertically arranged in the chamber of the reaction bed. The lower part of the reaction tubes is equipped with a support net containing the catalyst. The support net is supported and fixed by the support net support. The gas storage chamber at the bottom of the reactor communicates with the hydrogen gas collection chamber on the upper part of the reactor, so that gaseous methanol is sucked into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com