Installation for producing a hot-rolled strip

A hot-rolled strip and equipment technology, applied in metal rolling and other directions, can solve the problems of reduced yield, large wet refractory furnace lining, and tundish size limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

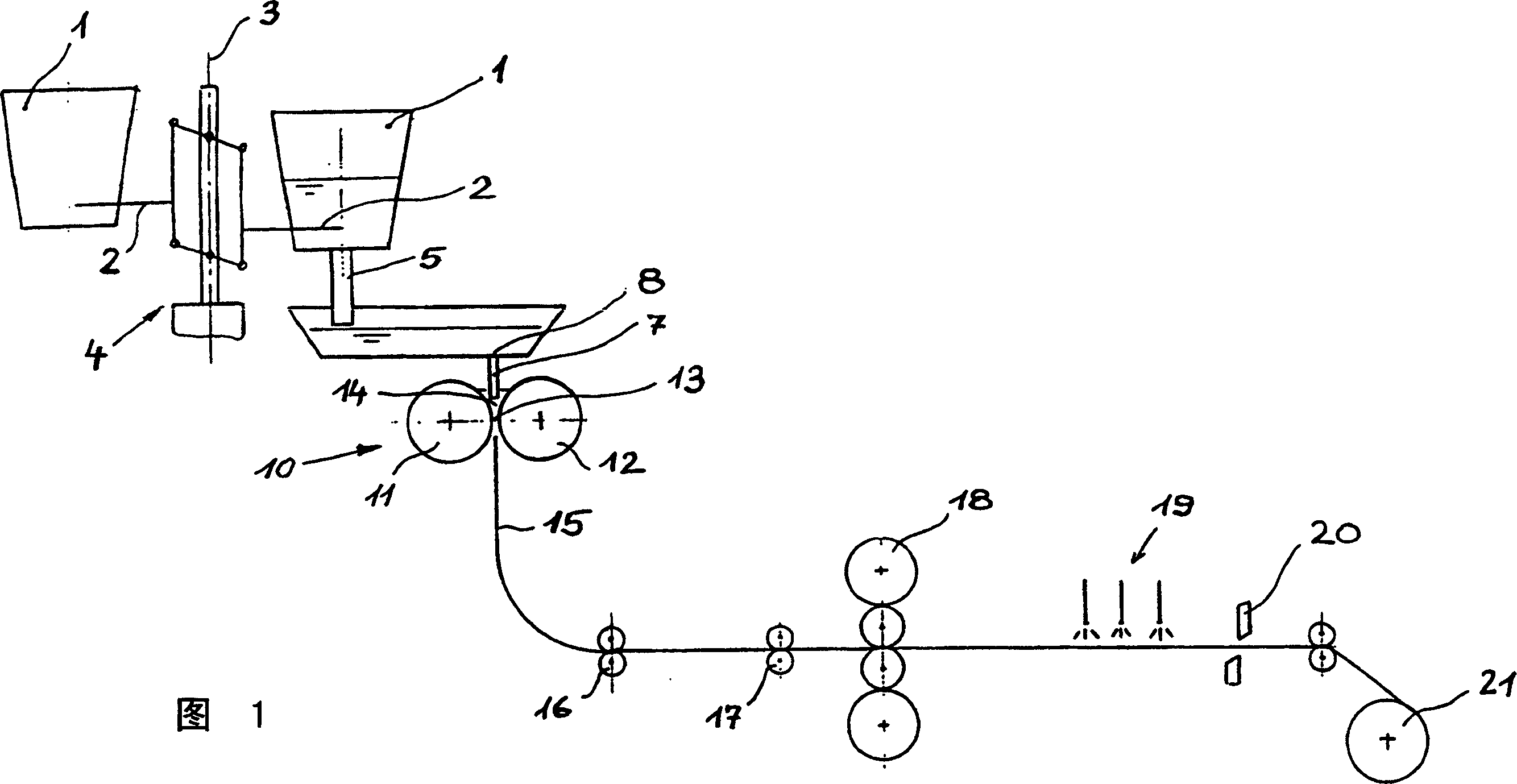

[0025] 1 schematically shows in longitudinal section an overall plant for the production of steel strip from molten steel according to the above-mentioned twin-roll casting method, as is conventional according to the prior art, but limited to the essential parts of the plant. The ladle 1 filled with molten steel is conveyed from the smelting operation to the casting plant by means of a metallurgical trolley or a plant crane (not shown) and from there is inserted into the support 2 of a ladle turret 4 rotating about a vertical axis 3 . From the ladle 1 that has been moved into the casting position, molten steel flows through a melt outlet 5 into a tundish 6 and from there through a bottom outlet 8 formed by a submerged gate 7 to a twin-roll continuous casting device 10 . The twin-roll caster 10 essentially consists of two driven casting rolls 11 , 12 that rotate counter to one another, which are supported via support bearings in a support frame (not shown). The casting rolls 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com