Method for producing decolorizer of edible oil

A production method and technology of decolorizing agent, which can be applied in the direction of producing fat, fat oil/fat refining, etc., can solve the problem of high price of activated clay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

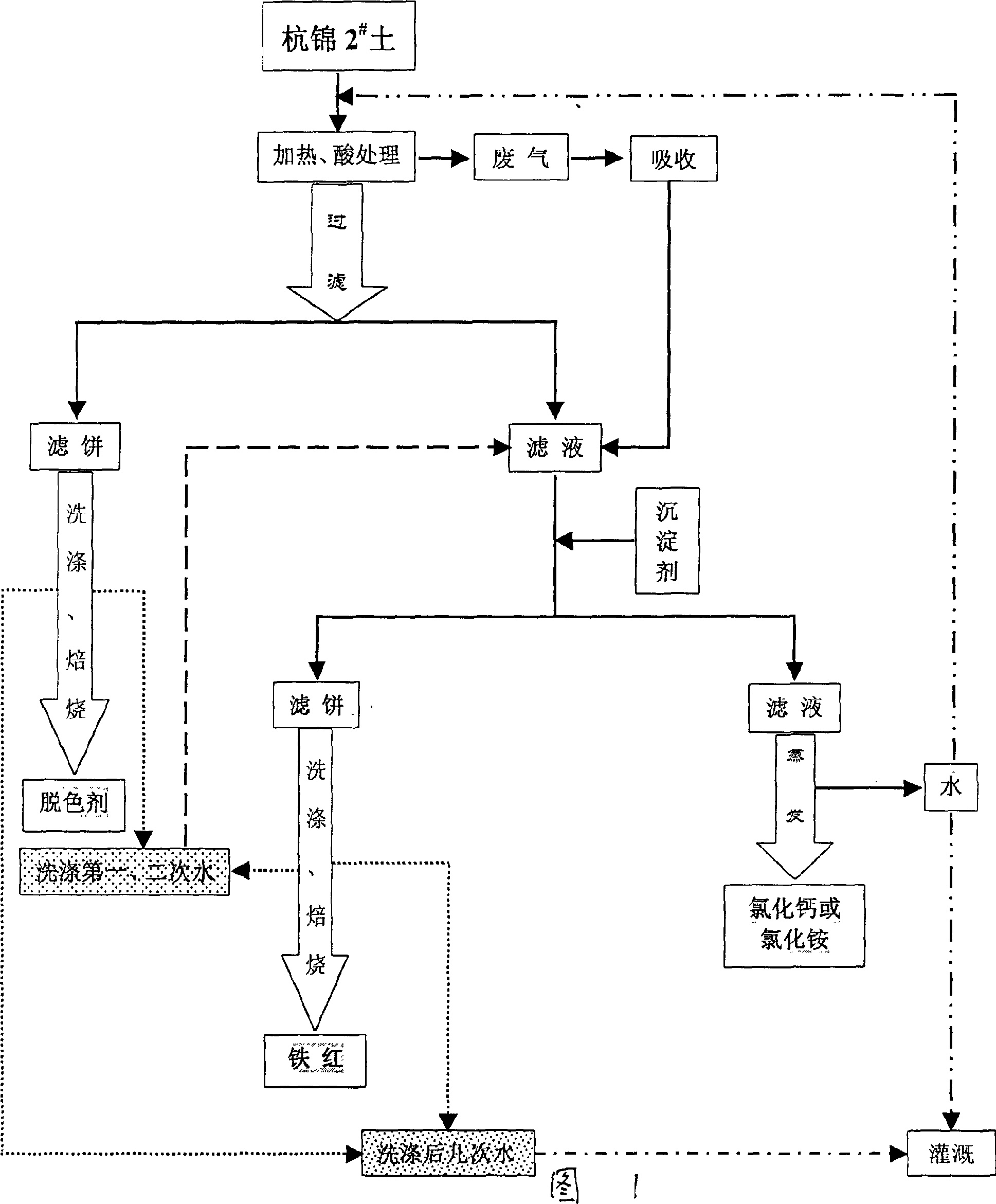

[0022] As shown in Figure 1, 1000 kg of Hang Jin 2 # Crush the soil into 20 meshes, soak and mix with 800 kg of hydrochloric acid solution and boil for 60 minutes, and keep stirring, absorb waste acid gas with ammonia water, filter to obtain filter cake, collect the filtrate, wash the filter cake with water until nearly neutral, After the washed filter cake is naturally air-dried, it is sent into a high-temperature furnace and roasted at 300° C. for 2 hours, then cooled and pulverized into 250 meshes to obtain 700 kilograms of edible oil decolorizer. The above-mentioned absorption liquid and filtrate of absorbing waste acid gas with ammonia water are combined with the first and second washing water for washing the filter cake, neutralized with ammonia water precipitation to a pH value of 8, and filtered to obtain Fe(OH) 3 The filter cake is precipitated, and then washed with water, dried at 105°C, and then roasted at 490°C to obtain 57 kg of iron red, and the filtrate is evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com