Assembling type shaped material and use thereof

A profile and matching technology, applied in slender components, building components, buildings, etc., can solve the problems of degumming and harmful substance discharge exceeding standards, lagging profile connection technology, and unsuitable connection structure, etc., to improve the appearance and shape. Simple, distortion-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

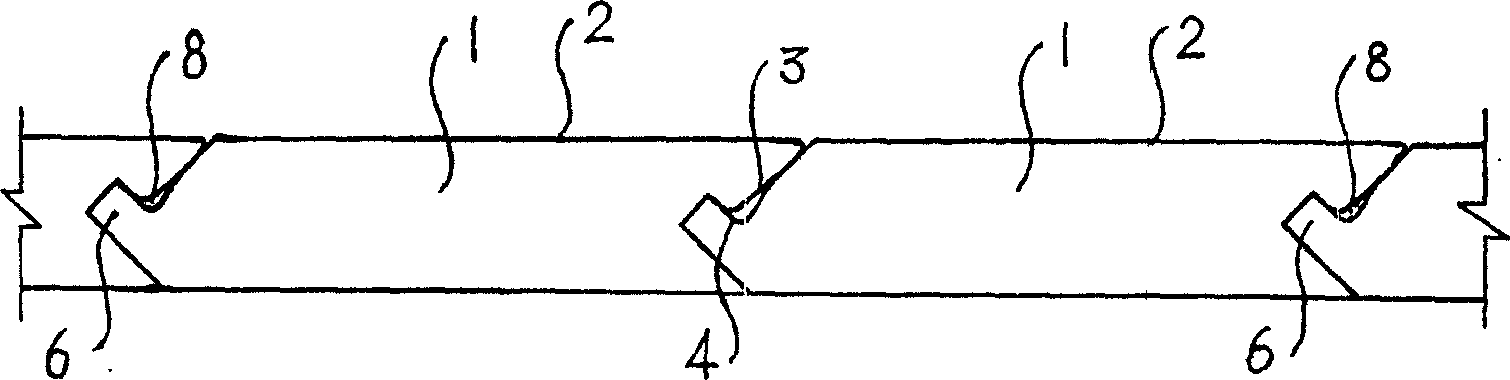

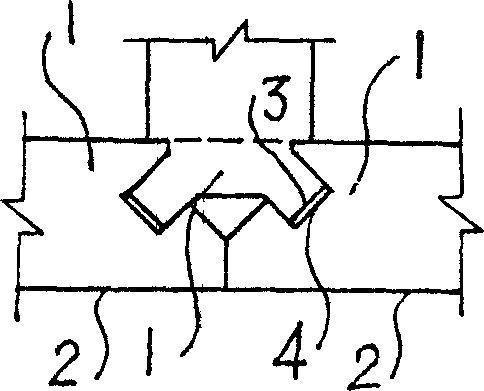

[0017] Example as figure 1 As shown, a rectangular wallboard (brick) 1 has the same width between the boards, and the appearance is basically the same. There are interlocking type sides 3 and 4 respectively around or along the length direction, and the interlocking type sides 4 in pairs. The molded sides 3 and 4 have at least one group of two parallel mating surfaces and the panel surface 2 with a rectangular concave-convex tenon structure 6 at an angle. Every two wallboards 1 are spliced with interlocking molded sides 3 and 4 to form a place for placing nail heads. Void 8, the gap 8 is groove-shaped along the longitudinal direction, so that the wallboard 1 can be directly or indirectly (with wooden strips, keels, splints or other bedding materials in the middle) and the wall nails after sand leveling and alignment. Connect and fix. Adjacent wallboards 1 are movably connected with interlocking sides 3 and 4, and are continuously spliced into a flat large board surface 2, ...

Embodiment 2

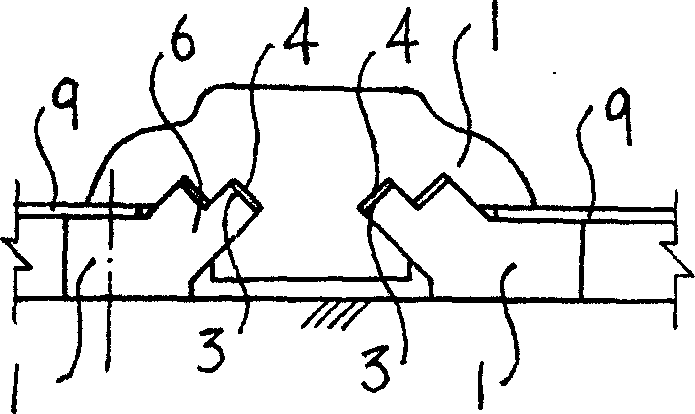

[0018] Embodiment 2 A decorative board, such as figure 2 As shown, each side of a pair of profiles 1 is the same interlocking profile 3 with the same shape, both or one of them is directly or indirectly fixed to the wall with expansion screws or other nails, if the latter is The other profile 1 is attached to the wall in a floating manner, and each pair of profile 1 is arranged in parallel, and each pair is arranged parallel and / or perpendicular to each other on the wall. The other profile 1 also has two interlocking sides 4 of the same shape, both of which are matched with the interlocking sides 3 of the profile 1 respectively. The two sides or the peripheral edges of the splint 9 are floatingly connected to the two profiles 1, or fixed to one of them (nailed or glued, etc.), and the splint 9 can be regarded as a structure on the profile 1.

Embodiment 3

[0019] Embodiment 3 Two or more wooden frames (spliced by wooden boards and strips, and can also include veneers, etc.) are fixed on one side or both sides with a number of fasteners 10. Described section bar 1 and erect ground. Several other profiles 1 are baffle plates with interlocking edges 4, which are movably matched with the interlocking edges 3 on the fastener 10, such as Figure 5As shown, the wall (such as the partition wall can also be fixed with the wall, the ground and / or the roof, including detachable fixing) and / or the cabinet frame is formed together. The panel can also consist of another type of profile 1 as described, including fixing the panel to the aforementioned profile 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com