Method and apparatus for large area photoetching by constant light source step scanning

A step-scanning, large-area technology, applied in optics, optical components, optomechanical equipment, etc., can solve problems such as low resolution, high cost, and inapplicability, and achieve flexible and variable field of view, structure and control Easy to improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

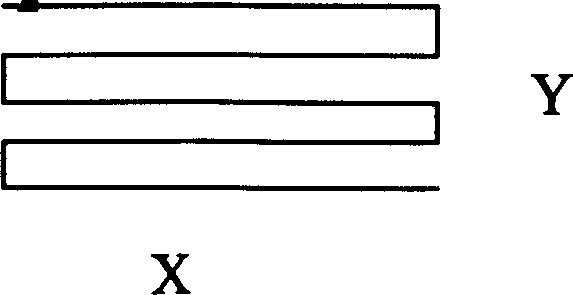

[0017] Such as figure 1 As shown, the scanning unit is a small light source with high uniformity and constant power. It uses the light source to scan step by step, scan along the X direction, and step by step along the Y direction for splicing. One exposure is completed through multiple scans.

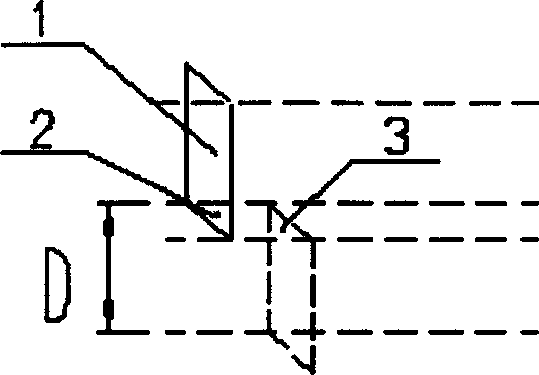

[0018] Such as figure 2 As shown, the scanning unit is a parallelogram, 1 is the scanning area, 2 is the scanning parallelogram unit, 3 is another scanning parallelogram unit, the scanning unit itself has high uniformity, and the step distance of each scan is D , the splicing parts 2 and 3 just compensate each other, and the power of the scanning unit is constant. In this way, the energy accumulation sum of any point in the area swept by the splicing part is equal to the energy accumulation sum of any point in the area swept by the unspliced part 1. Scanning completes one exposure. In addition, the scanning process can be multi-speed uniform scanning, and the scanning speed can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com