Container fixing method

A container, front-to-back direction technology, applied in packaging, deck loading, transportation and packaging, etc., can solve problems such as poor workability, longer ship stay time, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

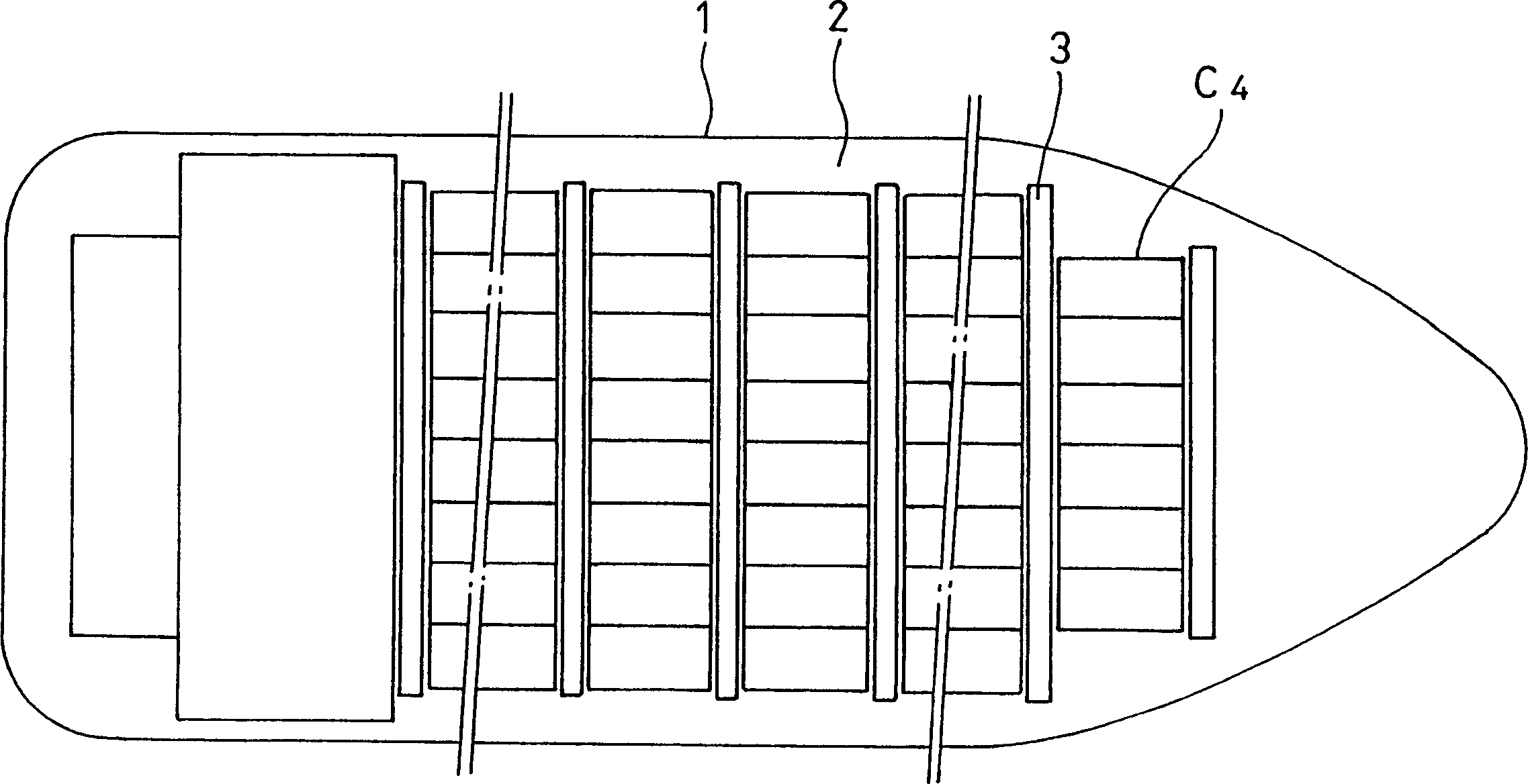

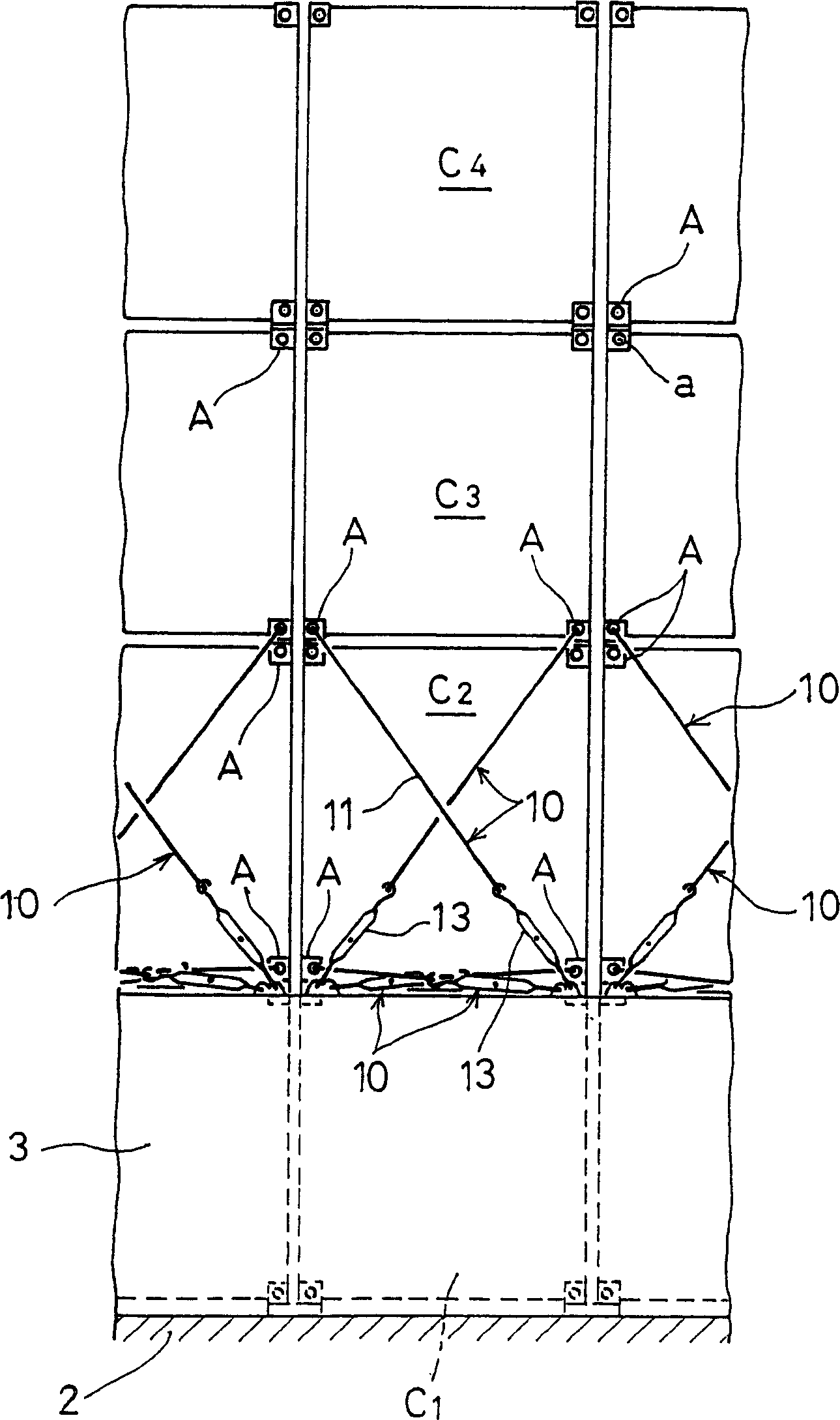

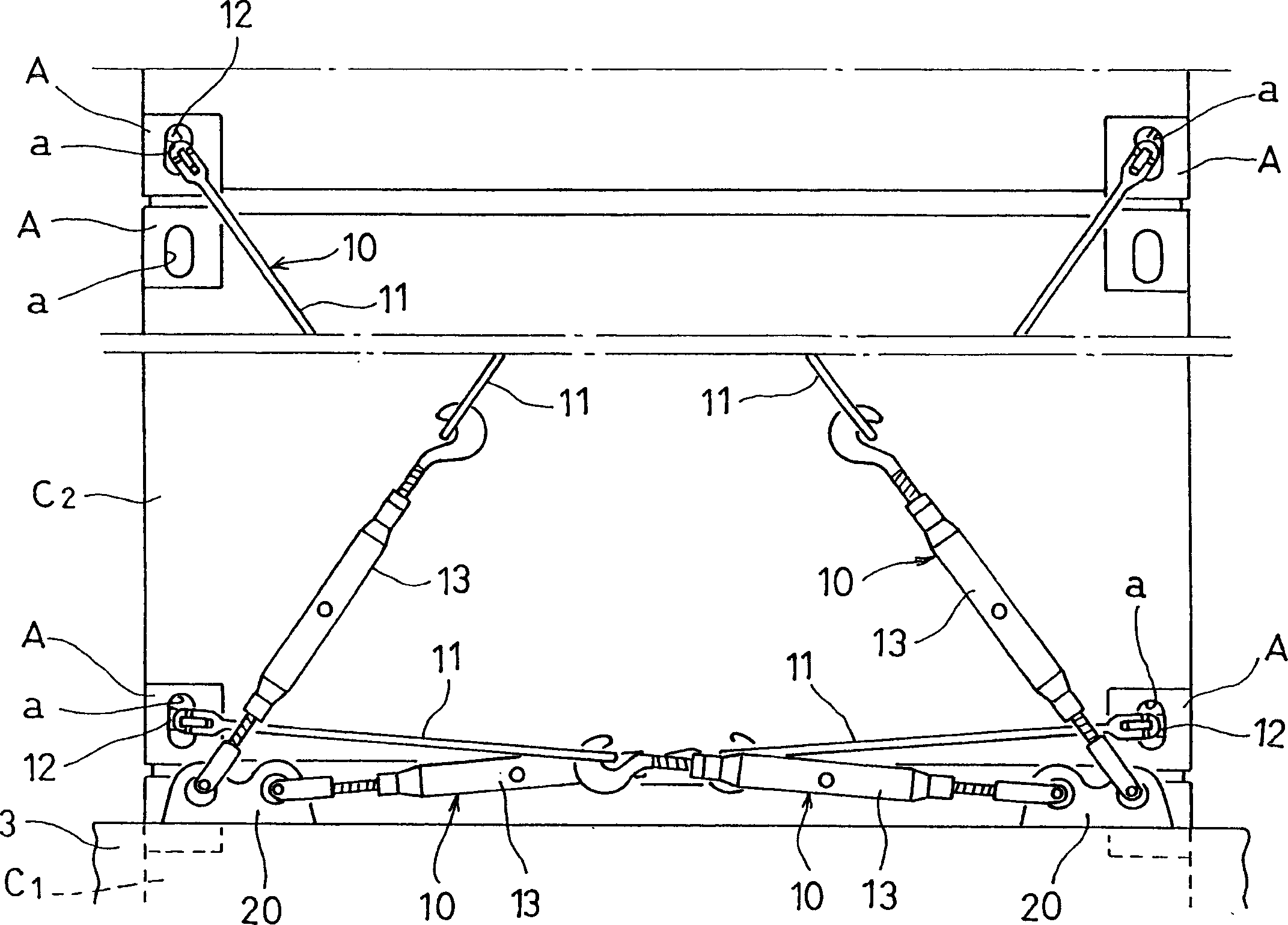

[0042] Embodiments of the present invention will be described below with reference to the drawings. Such as figure 1 As shown, on the deck 2 of the hull 1, a plurality of fastening bridges 3 extending along the side of the hull 1 are provided at intervals along the front and rear directions of the hull. The distance between the fastening bridges 3 at the front and rear is such that the container can be accommodated in the longitudinal direction. In addition, the height of the fastening bridge 3 is approximately an integer multiple of the height of a general-purpose container. Such as figure 2 As shown, in the embodiment, the height of the fastening bridge 3 is approximately equal to the height of the container.

[0043] Such as figure 2 As shown, on the deck 2, the first container C is stacked between the front and rear fastening bridges 3 1 ~Fourth Container C 4 , the stacked containers are arranged in multiple rows in the longitudinal direction of the fastening brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com