Two-leaf pull-push protective-wing type bullet-taking apparatus

A technology of wing protection and ball collection net, which is applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc., can solve the problems of low ball collection rate, poor strength, easy deformation, etc., and achieve large flow rate, Improve the service life and the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

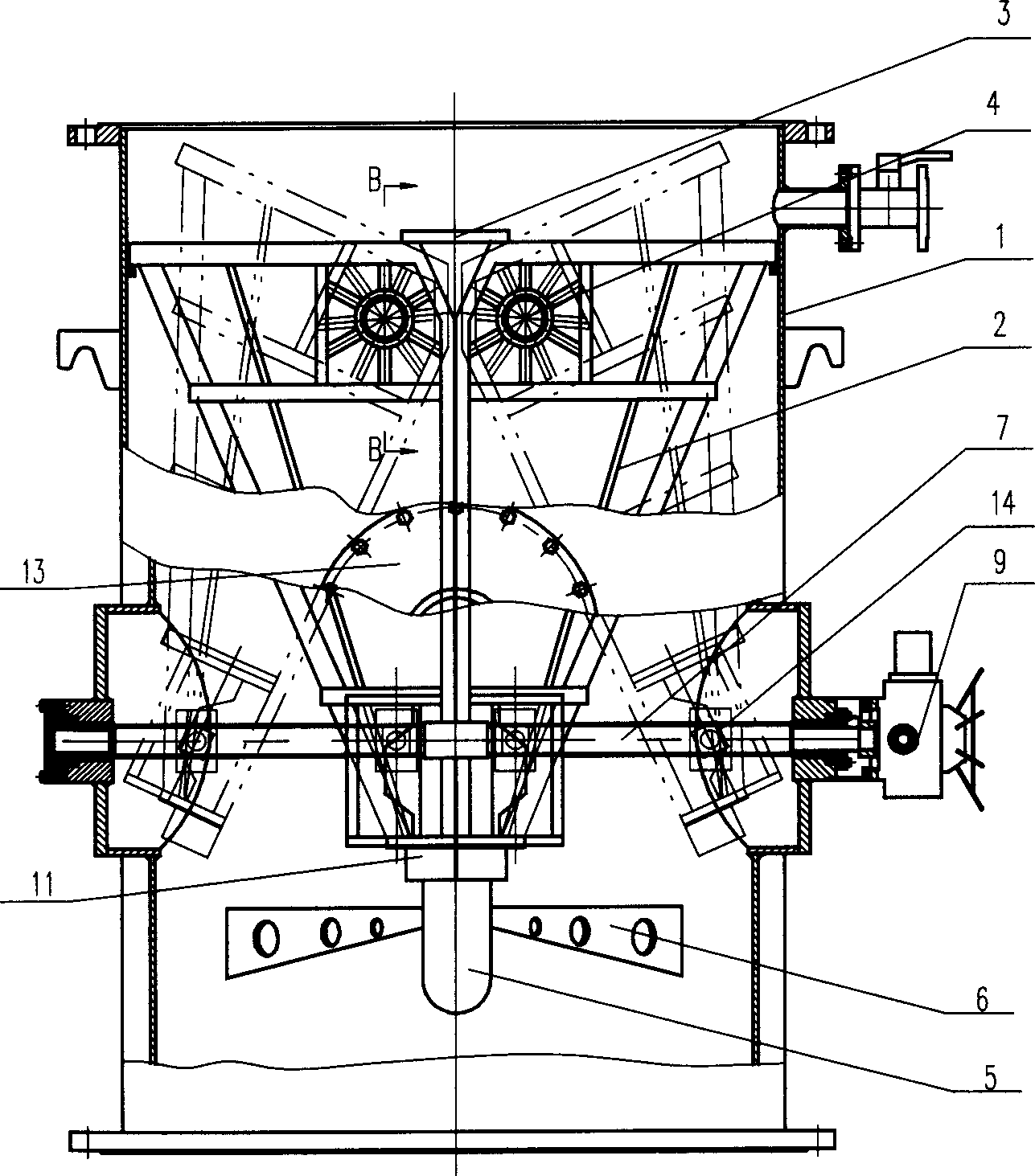

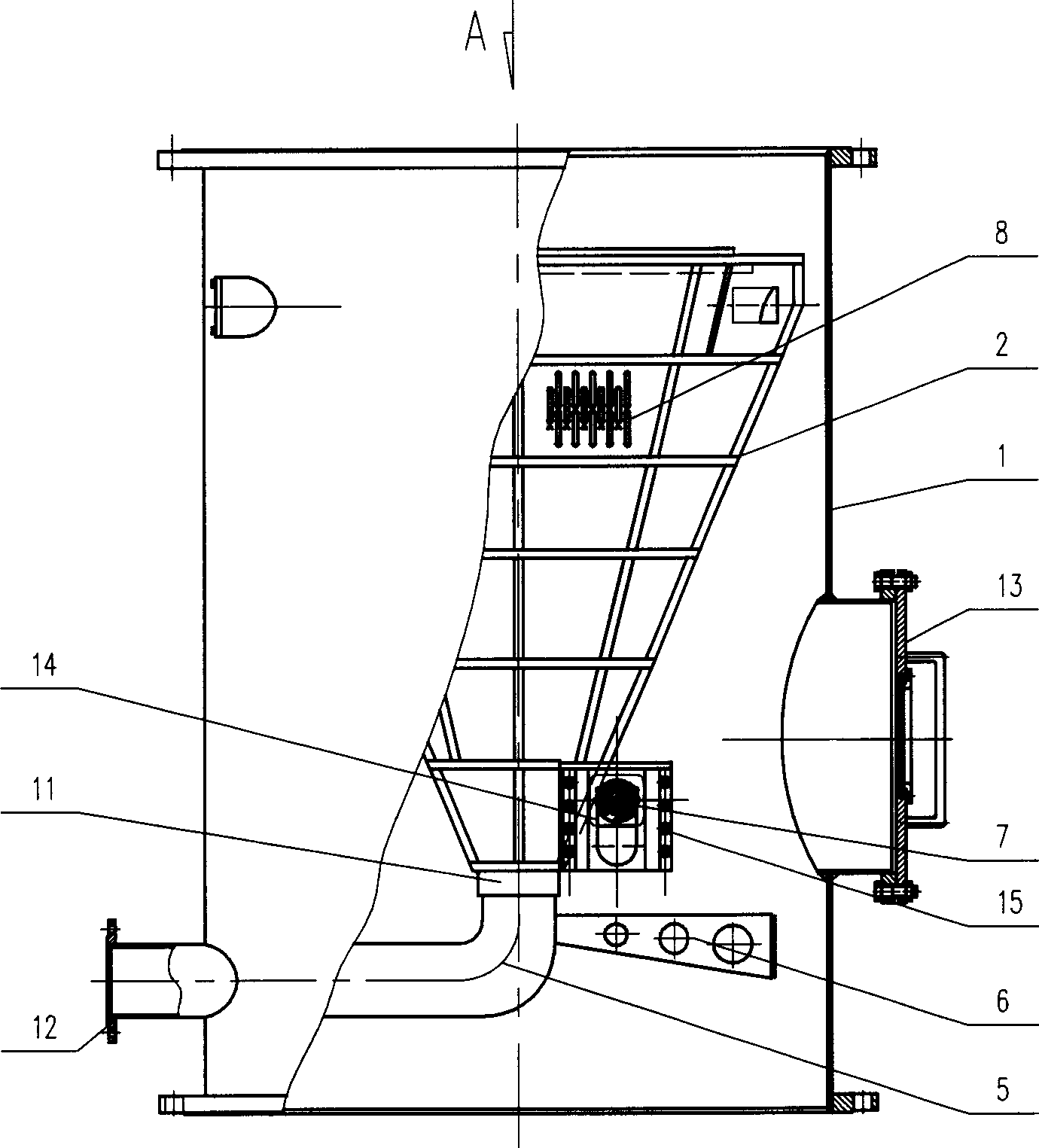

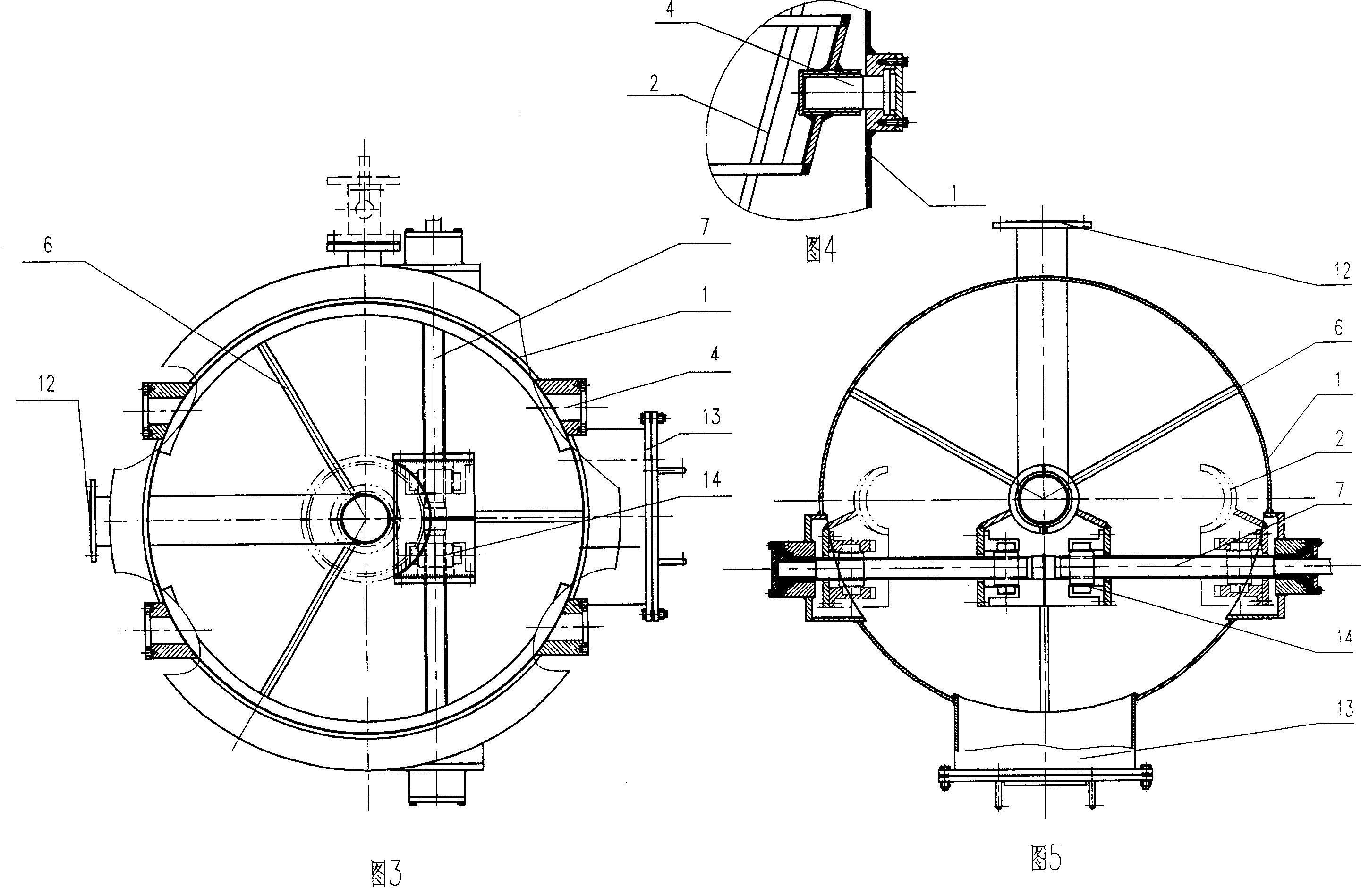

[0011] The present invention will be further described in detail below in conjunction with the drawings.

[0012] The double-leaf push-pull guard wing type ball collecting device of the present invention includes a ball collecting cylinder 1, a pin shaft 4, a transmission shaft 7, a driving actuator 9, a rubber ball outlet 12, and an observation hole 13. The transmission shaft 7 is fixed on the ball collecting cylinder On 1, one end of the drive shaft 7 is connected with the drive actuator 9. The ball collecting cylinder 1 is equipped with an observation hole 13, and the ball collecting cylinder 1 is equipped with a collecting net. The collecting net is in the shape of a funnel. The net frame 2 is composed of a net plate 8 attached to it; the net frame 2 of the retraction net adopts a large-slope curved surface design. The upper and lower ends of the ball-receiving net skeleton 2 are fixed to the ball-receiving cylinder 1 by pins 4, respectively, and the lower ends are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com