Pick jet nozzle of water jet loom

A water jet and nozzle technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of non-uniform water flow, large diffusion of jet water, and centrifugal force to promote diffusion, and achieve the effect of good uniformity and improved productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

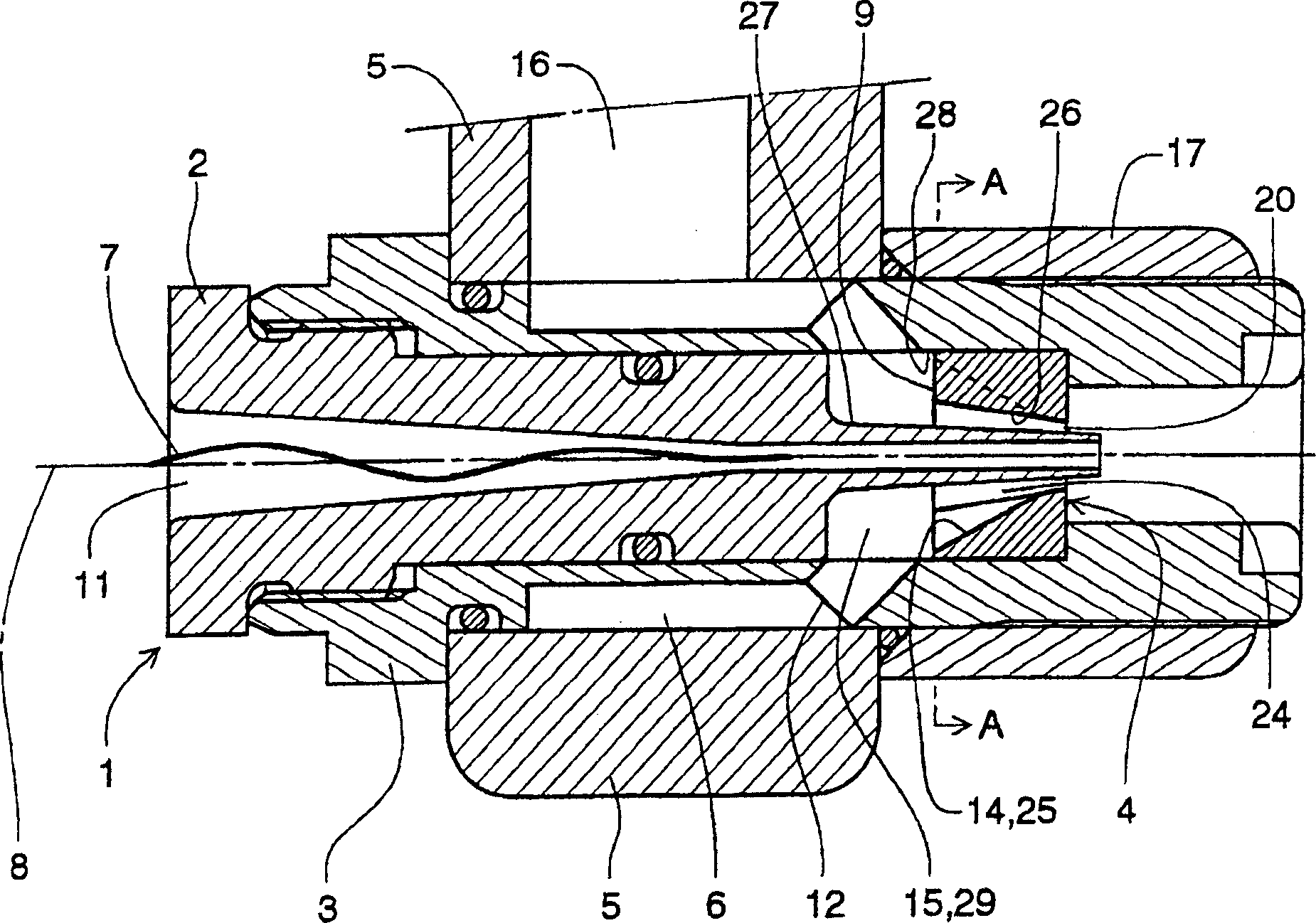

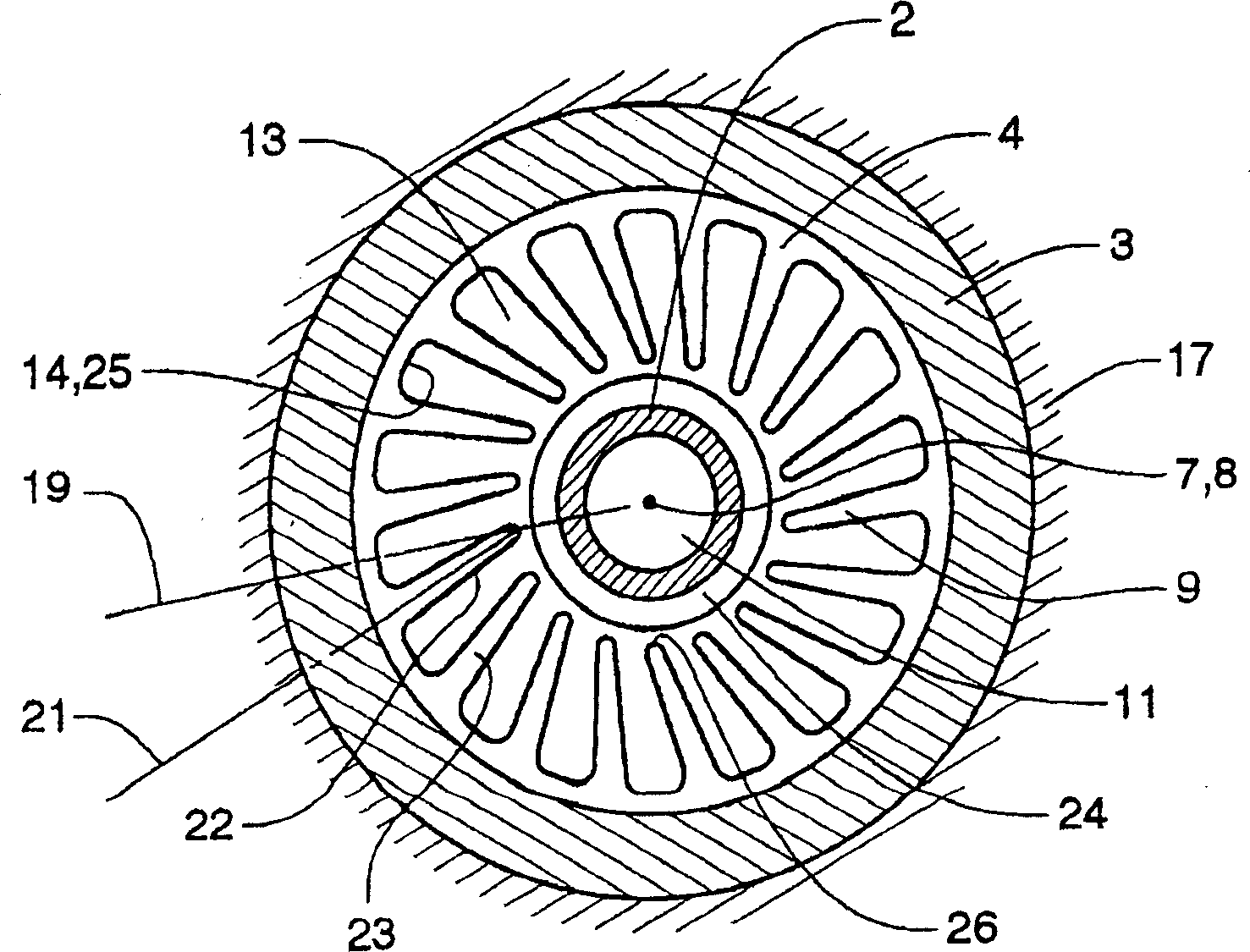

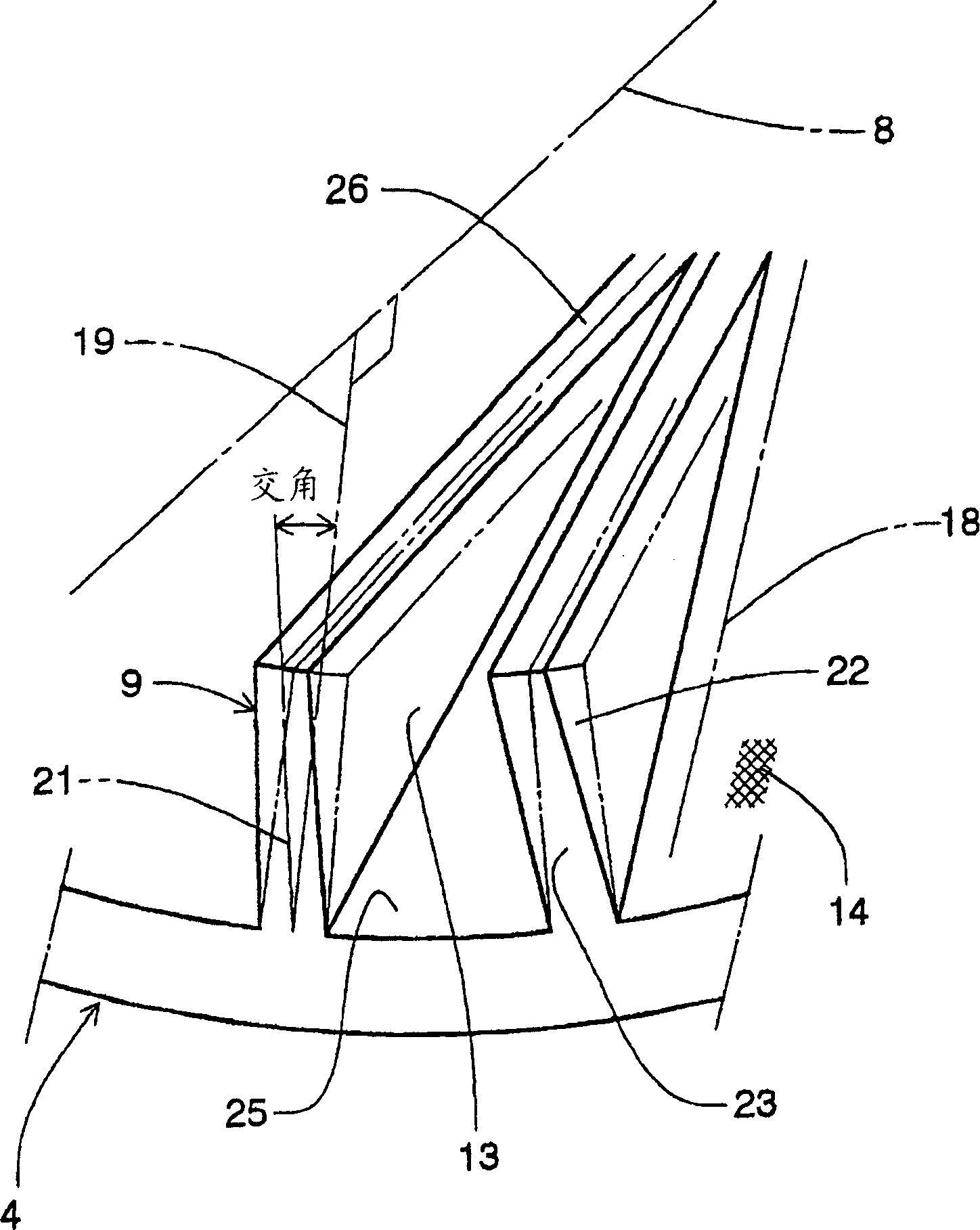

[0034] Figure 1A It is a side sectional view showing the shape of the weft insertion nozzle 1 of the water jet loom according to the present invention, the yarn guide hole 11 of the needle 2 penetrates in the direction of the nozzle axis 8, and the outer diameter portion changes stepwise in the yarn guide direction. Thin, thus forming a thin head shape to the front end. The nozzle main body 3 has a hollow portion formed by narrowing the inner diameter of the injection hole 20 on the right side in a step shape, and the straightening member 4 incorporating the straightening fins 9 is integrally accommodated at the bottom of the step.

[0035] The needle 2 is inserted into the hollow portion 29 so as to coincide with the axis of the nozzle body 3, and the annular chamber 15 is formed by the stepped outer peripheral surface 27 of the needle 2 and the inner perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com