Wiring harness and wire harness manufacturing method

A wire harness and wire technology, applied in the field of wire harnesses, can solve the problems of difficulty in reducing the cost of manufacturing wire harnesses and automation of assembly processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Referring to the accompanying drawings, the embodiments of the present invention will be described in detail below. Herein, in the process of explaining the following embodiments, the same reference numerals are used to designate the same components in order to simplify or omit the corresponding explanations.

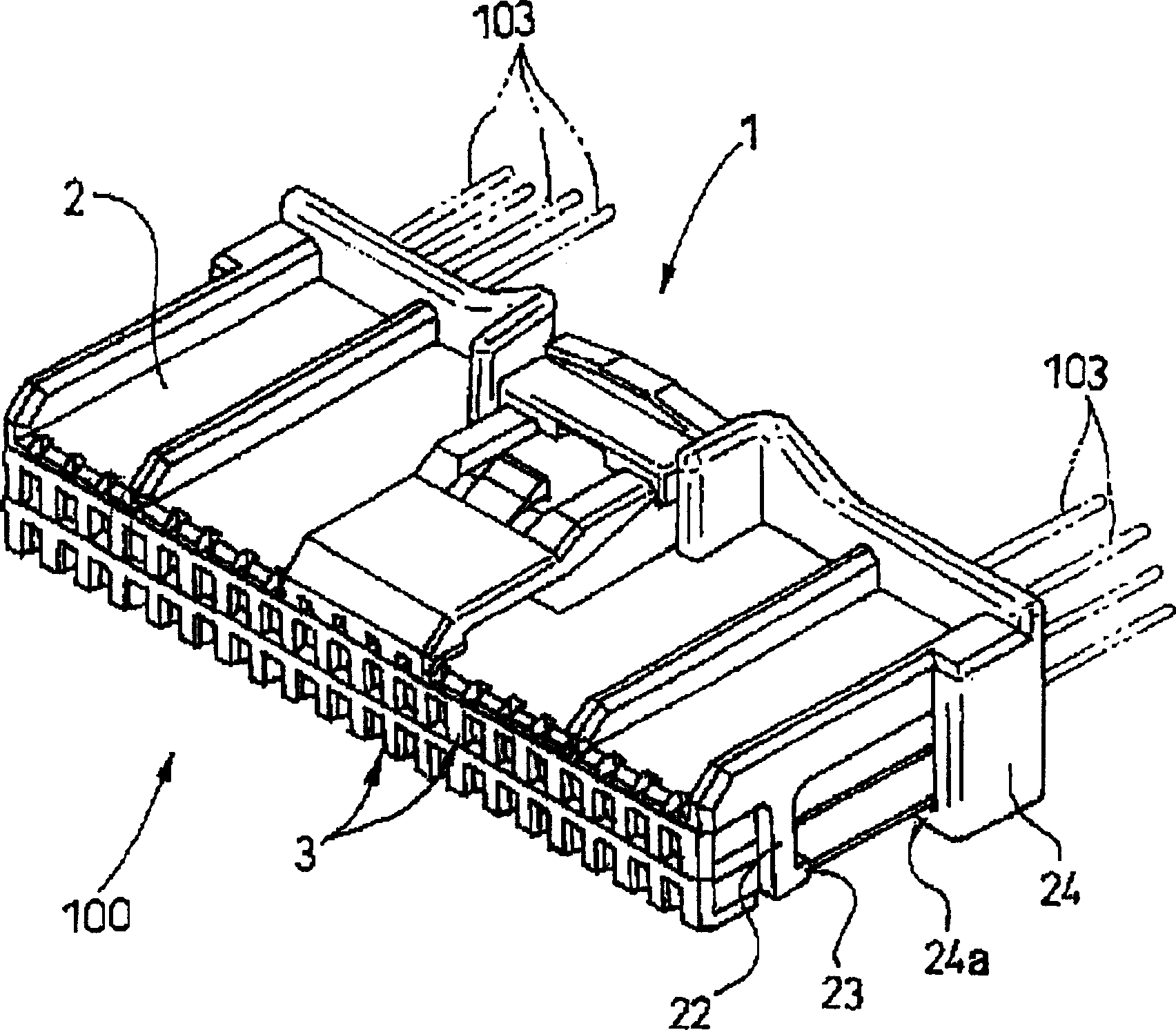

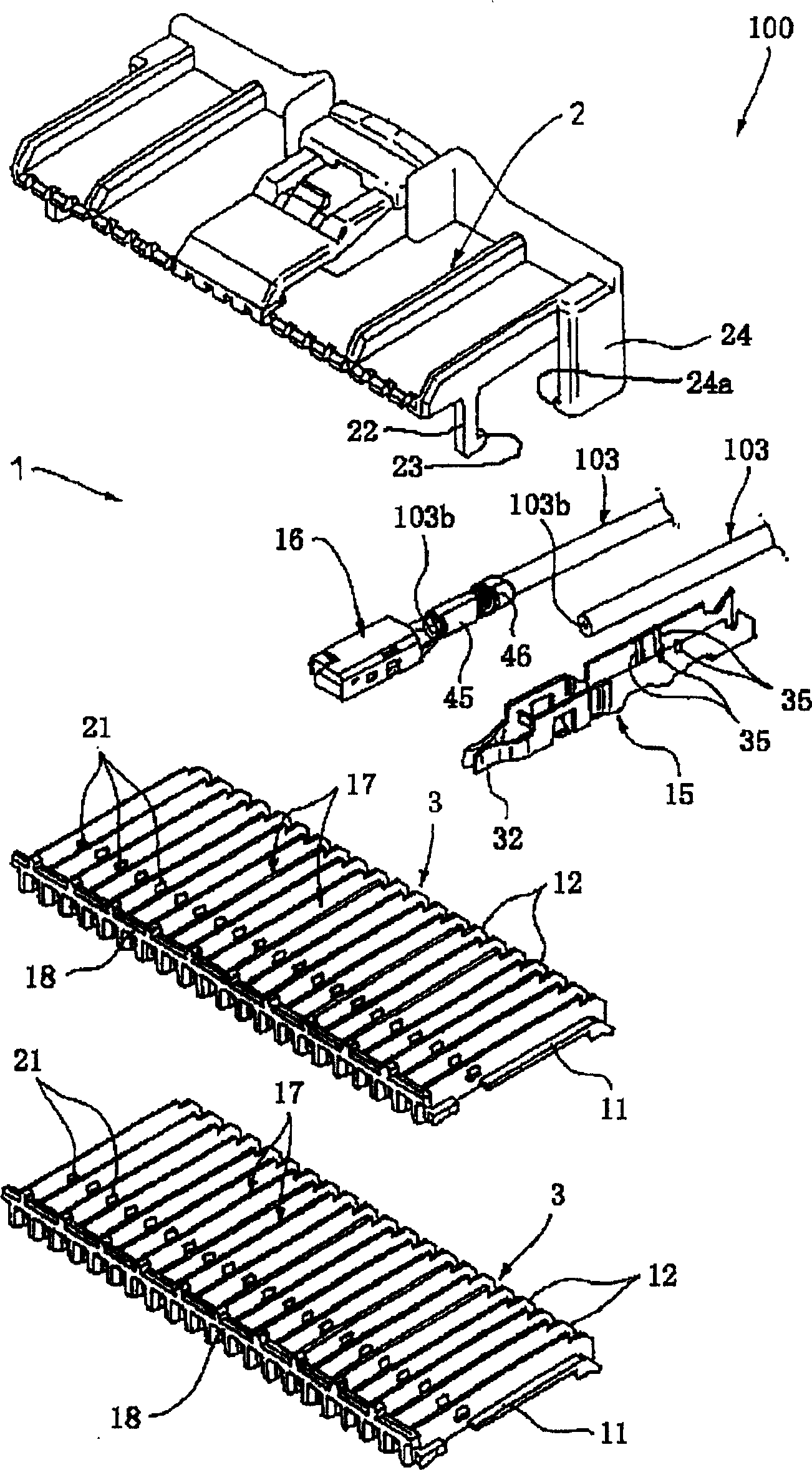

[0057] Such as figure 1 with 2 As shown in , the wire harness 100 according to the first embodiment of the present invention includes a connector 1 for accommodating a plurality of crimp terminals 15 and crimp terminals 16, wherein the crimp terminals 15 and crimp terminals 16 are respectively connected to a large number of electric wires 103 connections.

[0058] The connector 1 includes insulating housings 3 , 3 , in which crimp terminals 15 or crimping terminals 16 can be arranged separately, and a cover 2 capable of fixing the insulating housings 3 , 3 .

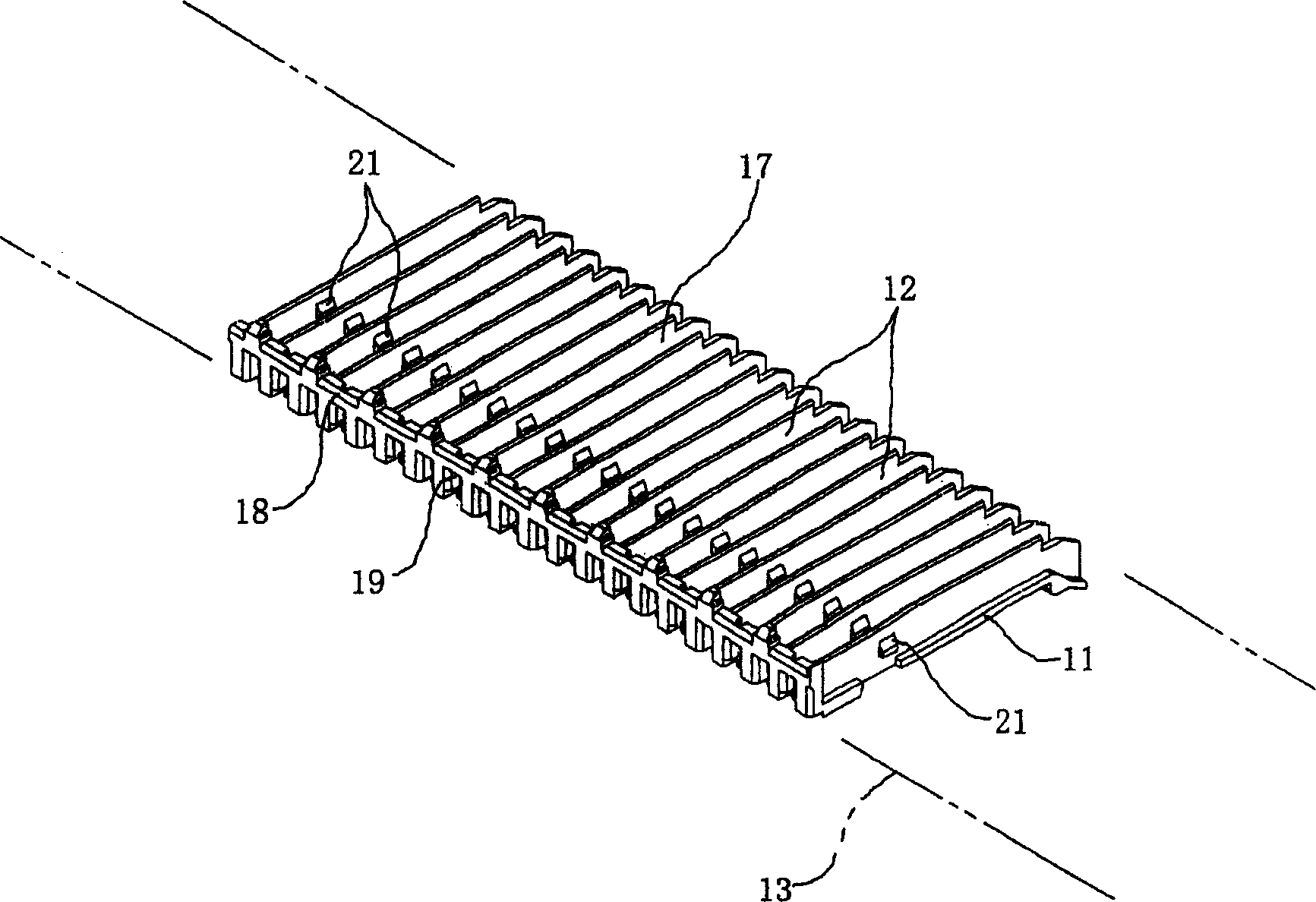

[0059] Such as image 3 As shown in , the insulating case 3 has partition walls 12 , and these part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com