Pixel structure

A pixel structure, pixel technology, applied in optics, instruments, electrical components, etc., can solve problems such as failure, complicated driving circuit design and manufacturing, and pixel structure cannot operate normally, and achieve the effect of uniform electric field distribution and simplified design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

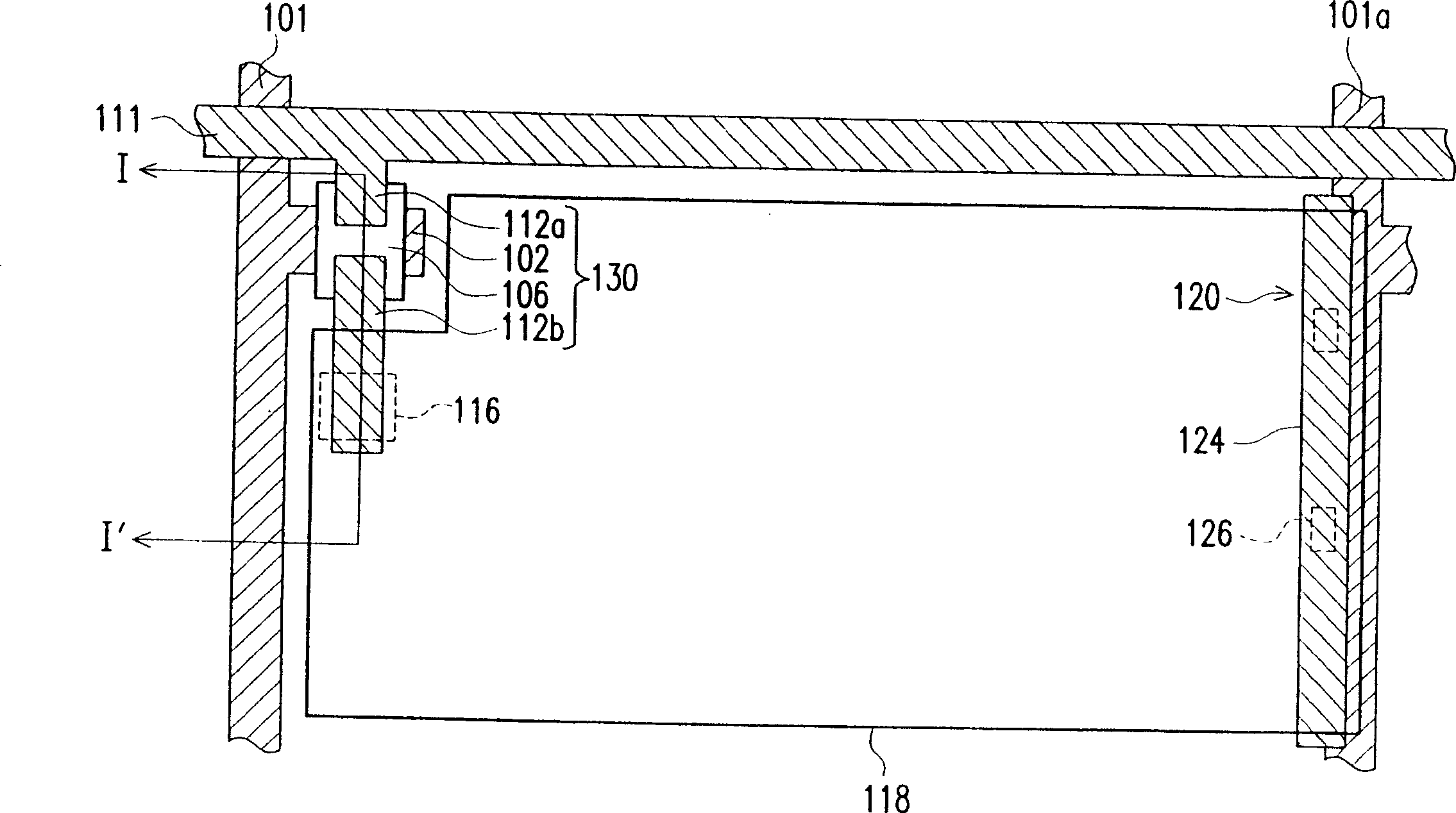

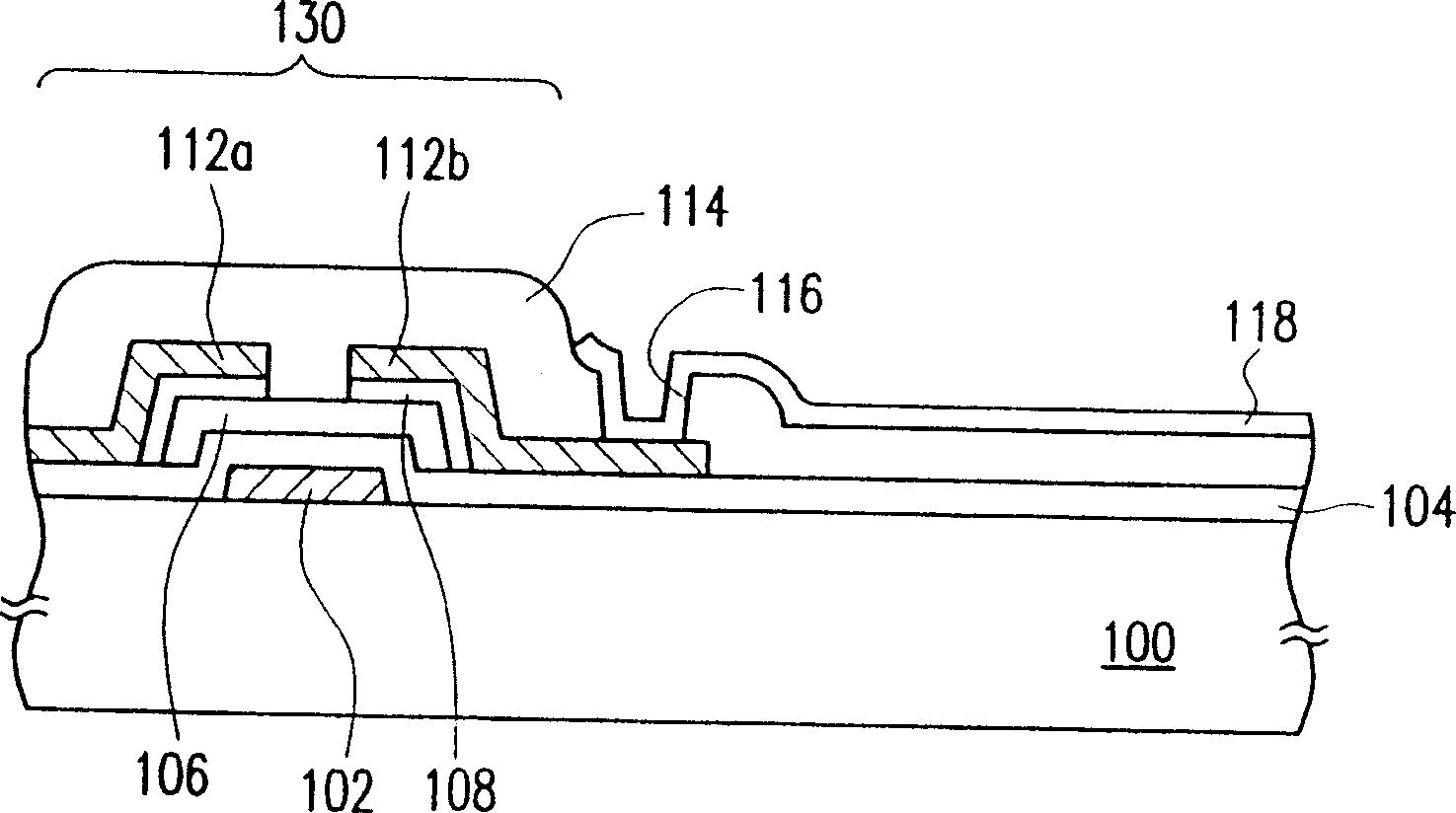

[0024] Such as image 3 , which shows a top view of a pixel structure according to a preferred embodiment of the present invention; and Figure 4 shown as image 3 The schematic diagram of the II-II' section in .

[0025] Please refer to image 3 and Figure 4 , the manufacturing method of the pixel structure of the present invention first provides a substrate 200, wherein the substrate 200 is, for example, a transparent glass substrate or a transparent plastic substrate. Next, a scan line 201 and a gate 202 are formed on the substrate 200 , wherein the scan line 201 is electrically connected to the gate 202 .

[0026] Afterwards, a gate dielectric layer 204 is completely formed on the substrate 200 to cover the scan lines 201 and the gates 202 . The material of the gate dielectric layer 204 is, for example, a dielectric material such as silicon nitride or silicon oxide.

[0027] Next, a channel layer 206 is formed on the gate dielectric layer 204 above the gate 202, whe...

no. 2 example

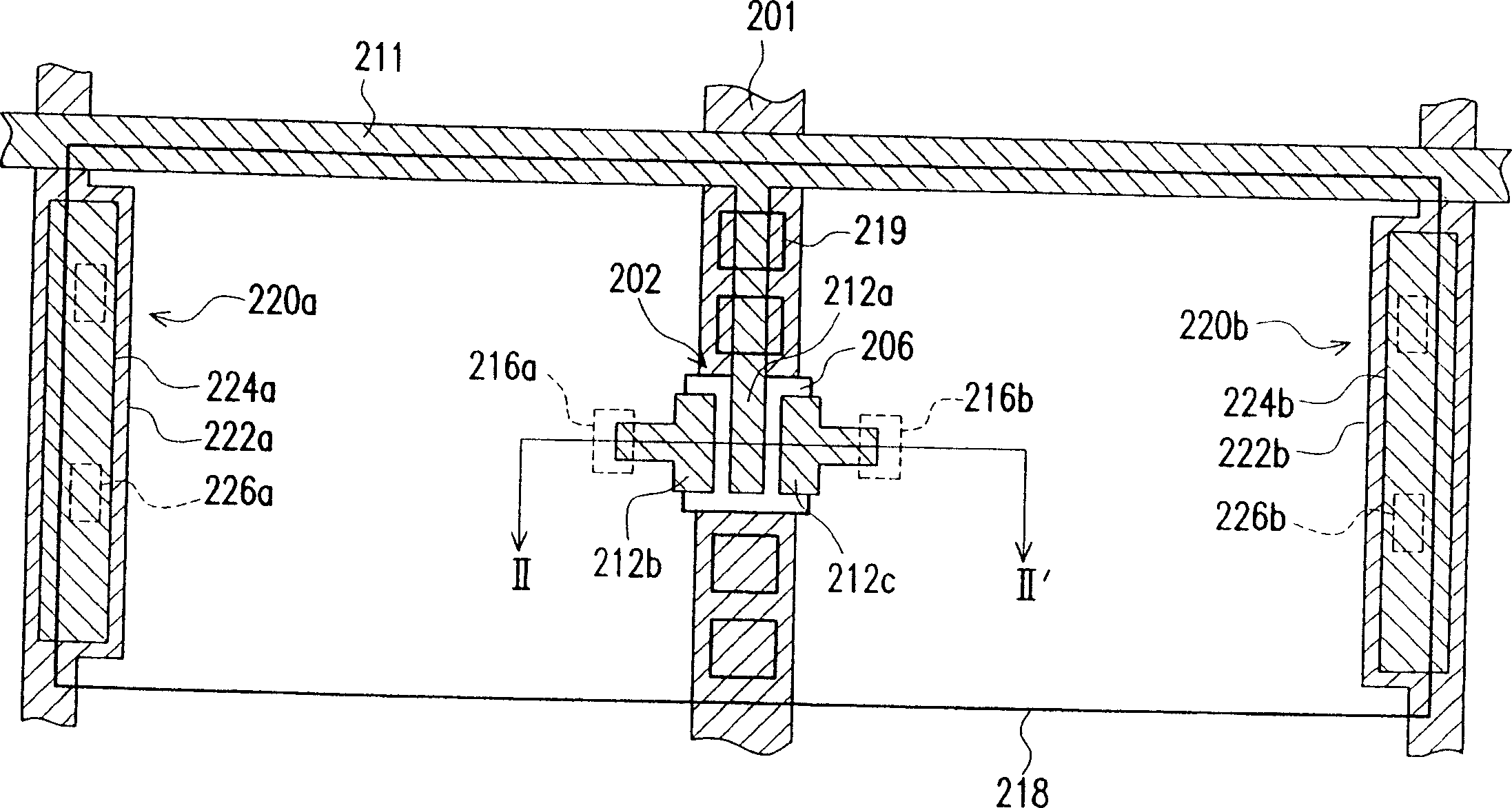

[0038] Figure 5 Shown is a top view of a pixel structure according to another preferred embodiment of the present invention; Figure 7 shown as Figure 5 The schematic diagram of the III-III' section.

[0039] Please refer to Figure 5 and Figure 7 The manufacturing method of the pixel structure in this embodiment is to firstly provide a substrate 300, wherein the substrate 300 is, for example, a transparent glass substrate or a transparent plastic substrate. Next, a scan line 301 and a gate 302 are formed on the substrate 300 , wherein the scan line 301 is electrically connected to the gate 302 .

[0040] Afterwards, a gate dielectric layer 304 is completely formed on the substrate 300 to cover the scan lines 301 and the gates 302 . The material of the gate dielectric layer 304 is, for example, a dielectric material such as silicon nitride or silicon oxide.

[0041] Next, a channel layer 306 is formed on the gate dielectric layer 304 above the gate 302 , wherein the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com