Laminated fuel cell and its maintaining method

A fuel cell, stacked technology, used in fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of dead space, large size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

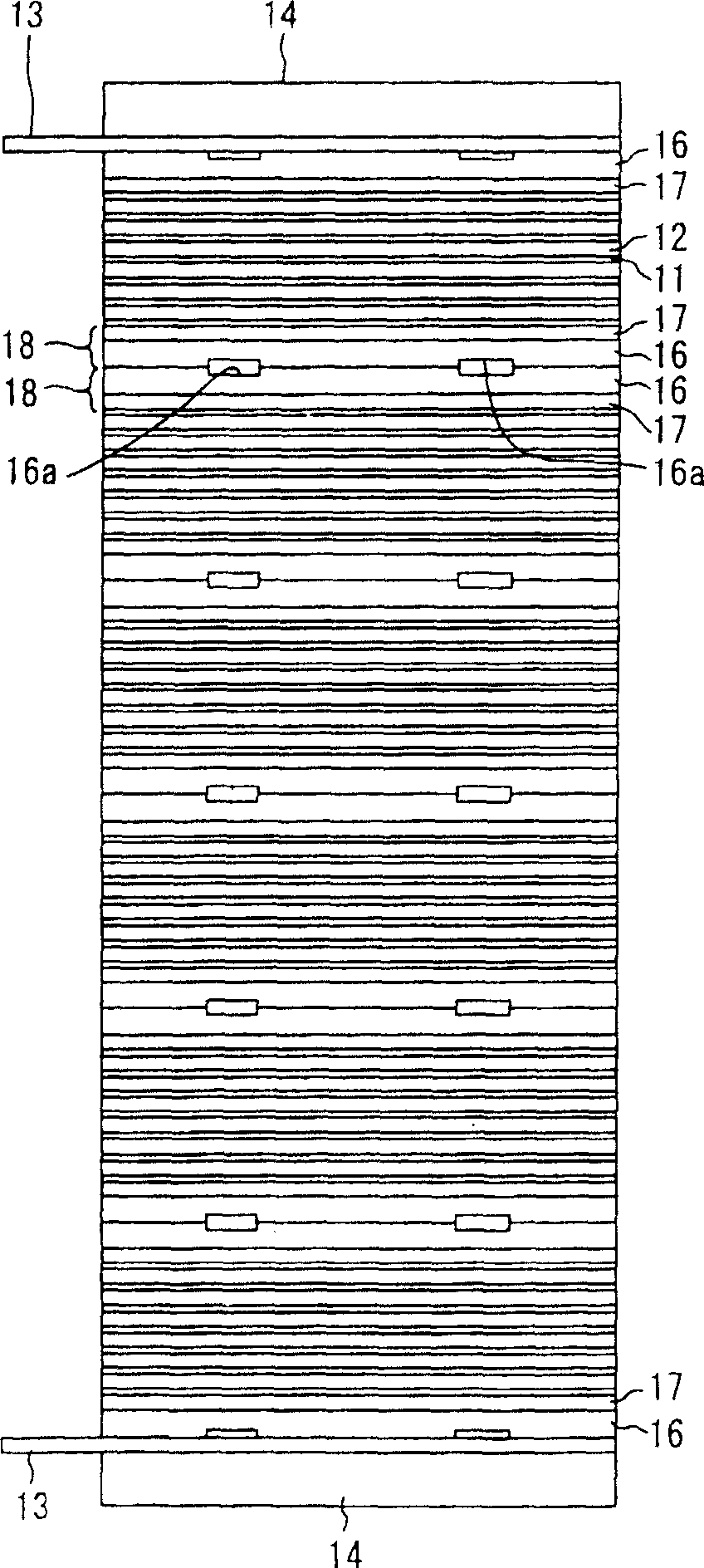

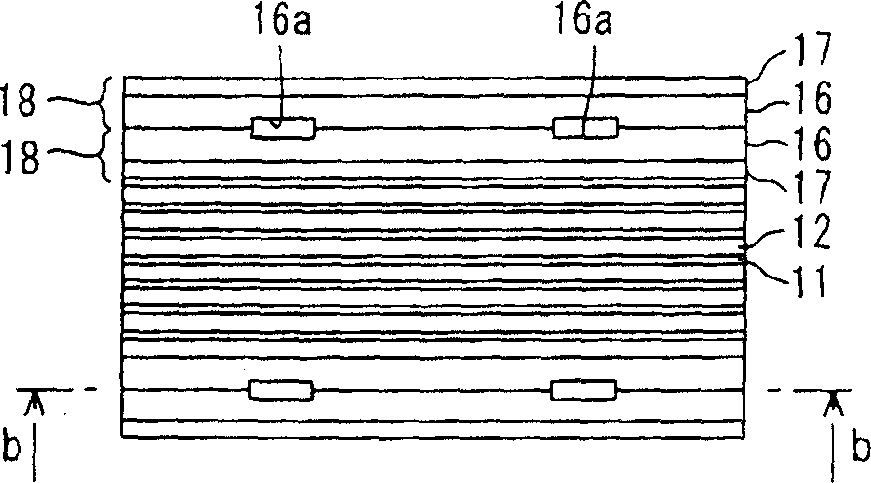

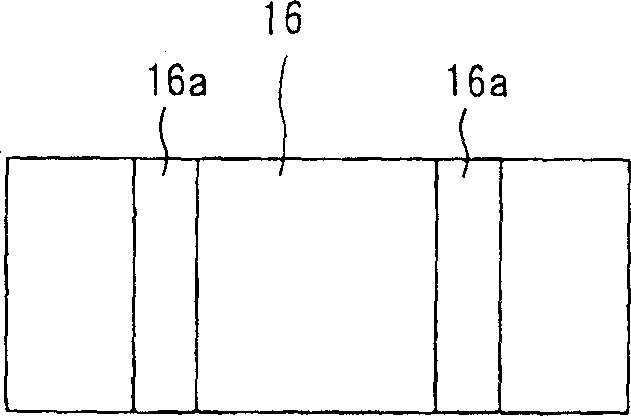

[0025] will now refer to Figures 1 to 4a , 4b describe the first embodiment of the stacked fuel cell of the present invention and its maintenance method. figure 1 A schematic diagram of a stacked fuel cell. Figure 2a and 2b yes figure 1 local enlargement. image 3 It is an explanatory diagram of a method for maintaining a stacked fuel cell. Figure 4a and 4b yes image 3 A partial enlargement of the .

[0026] Such as Figure 1 to Figure 4a As shown in and 4b, the stacked fuel cell of the present invention includes a plurality of cell membranes 11 and a plurality of separators 12 stacked alternately. The cell membranes 11 each comprise a solid polymer electrolyte membrane sandwiched between electrode membranes made of graphite, while the separators 12 are conductive graphite separators and each have a fuel gas passage formed on one surface thereof, and Oxidant gas channels formed on the other surface. In the stacked fuel cell, a plurality of separator plates 18 a...

no. 2 example

[0037] will now refer to Figure 5 and 6 A second embodiment of the stacked fuel cell and its maintenance method of the present invention will be described. Figure 5 is a schematic diagram of the structure of a stacked fuel cell, Figure 6 yes Figure 5 A partial enlargement of the . For the same parts as in the first embodiment described above, the same explanations as in the first embodiment will be omitted by using the same symbols as in the contents of the explanation in the first embodiment.

[0038] Such as Figure 5 and 6 As shown, the stacked fuel cell of this embodiment includes a plurality of cell membranes 11 and a plurality of separators 12 stacked alternately. In the stacked fuel cell, a plurality of separator plates 28 are inserted at predetermined intervals in the stacking direction. The separator plates 28 each have a conductive graphite terminal plate 26 having a groove 26a forming a penetration through which the fastening member 19 passes in a directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com