Novel method for treatment of dye wastewater

A technology of dye wastewater and a new method, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increased treatment costs, secondary pollution, and difficult regeneration, and achieve Improved biodegradability and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

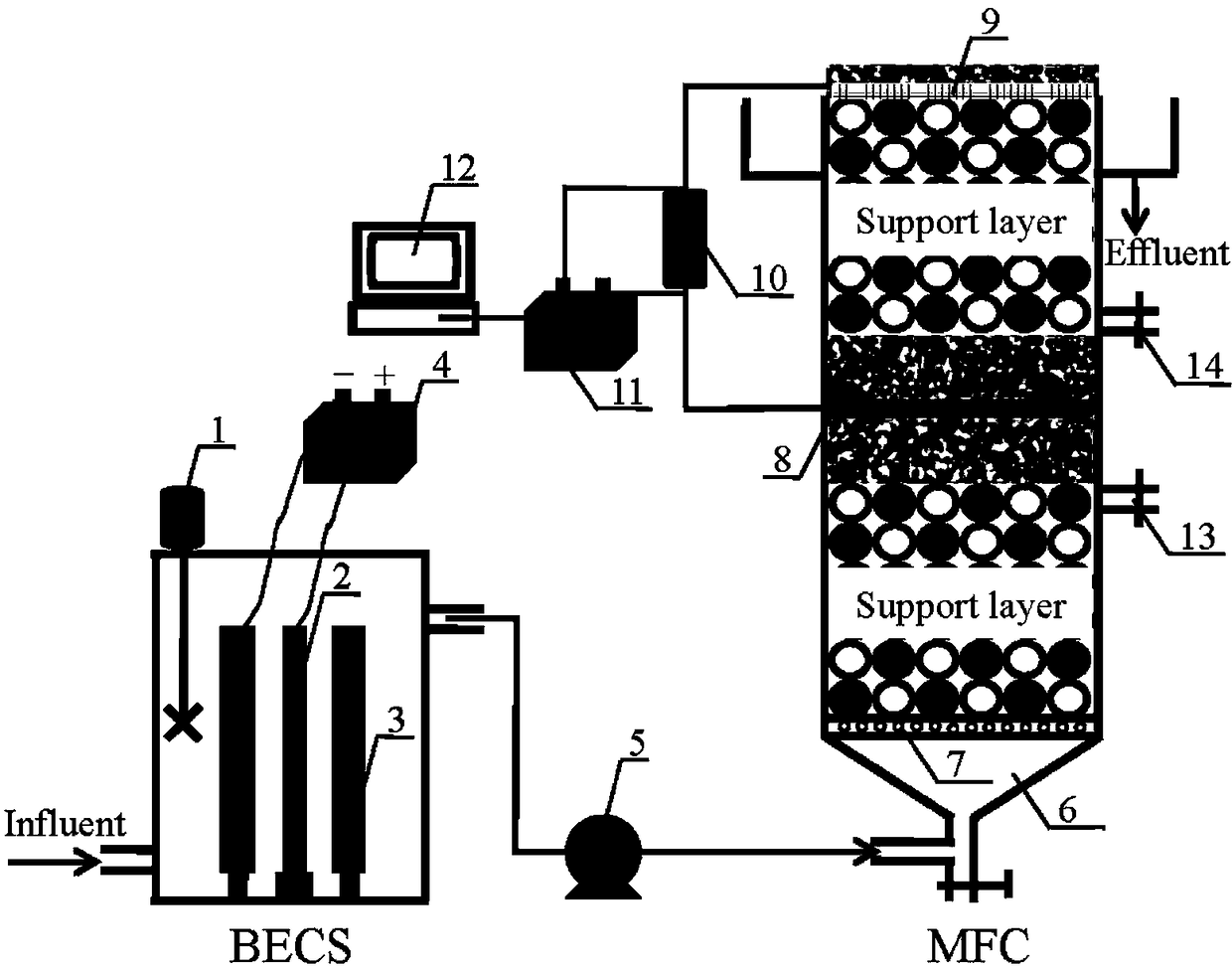

[0030] Through the peristaltic pump, the methyl red dye wastewater with a concentration of 20mg / L is continuously fed into the coupling system of the microbial electrolysis cell (BECS) and the microbial fuel cell (MFC). The working voltage of the electrolysis cell is 1.0V, and the hydraulic retention time is 3d; The COD removal rate is 40.6%, and the chroma removal rate is 94.5%; the COD removal rate of microbial fuel cell effluent is 97.8%, the chroma removal rate is 100%, and the output voltage is 0.62V.

example 2

[0032] Take 50L of dye wastewater from an Anhui Dyestuff Chemical Co., Ltd., and continuously pass it into the coupling system of electrolytic cell (EC) and microbial fuel cell (MFC). The working voltage of the electrolytic cell is 1.0V, and the hydraulic retention time is 3d; The COD removal rate of microbial fuel cell effluent is 96.5%, the color removal rate is 100%, and the output voltage is 0.60V.

[0033] It can be seen from the above examples that the present invention has a good treatment effect on the treatment of dye wastewater no matter it is simulated dye wastewater or actual dye wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com