Shock absorber of washing machine

A shock absorber and washing machine technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of reduced damping force of friction parts, increased noise and vibration of washing machines, and weakened performance of washing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

[0039] A drum type washing machine according to a preferred embodiment will be described with reference to the accompanying drawings.

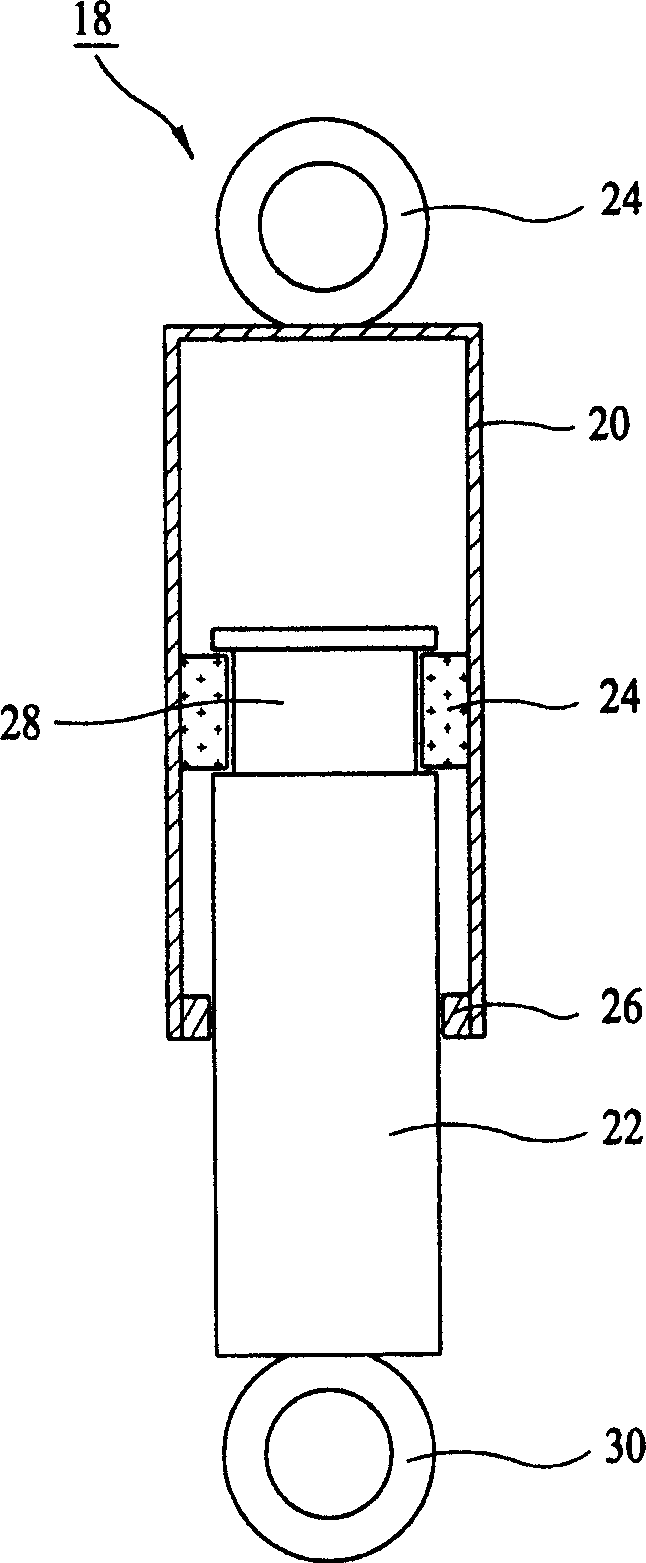

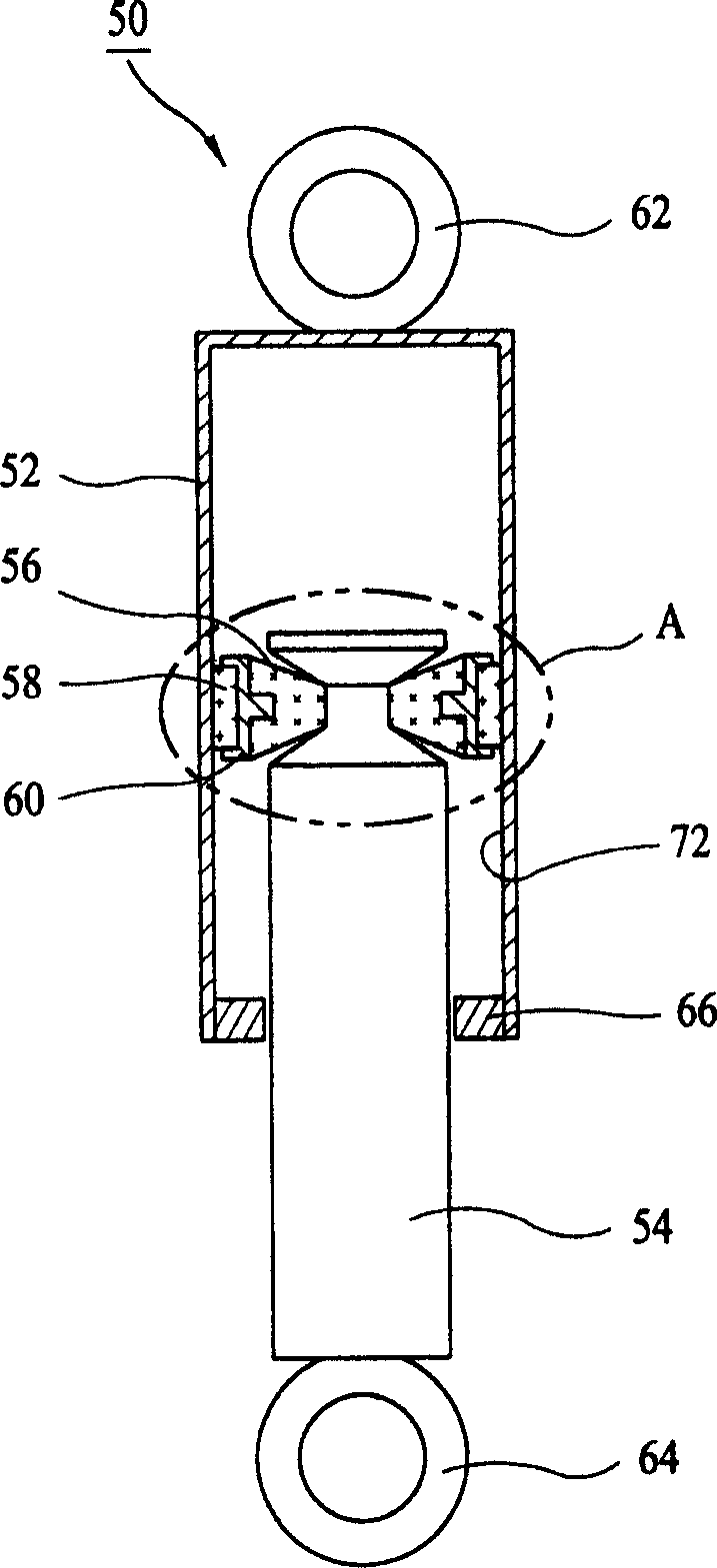

[0040] image 3 is a sectional view showing the shock absorber according to the first embodiment of the present invention.

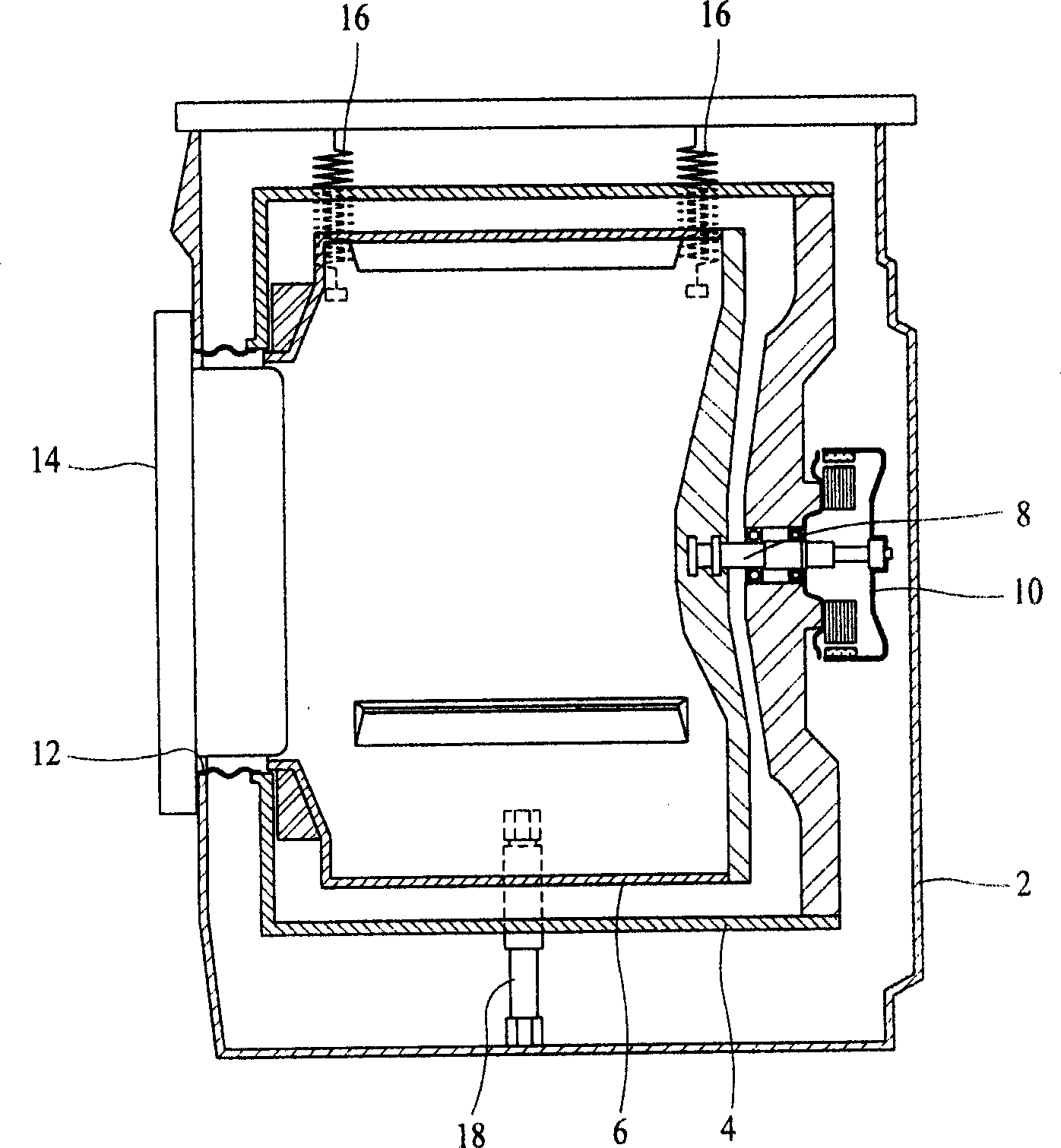

[0041] refer back figure 1 According to the washing machine of the present invention, the washing machine comprises a casing 2 constituting its exterior, a washing tub 4 which is arranged in the casing 2 and stores washing water, and a drum 6 which is rotatably arranged in the washing tub 4 and performs washing and dehydration operations on clothes. . In addition, the washing machine of the present invention also includes a plurality of support springs 16 installed between the top of the washing tub 4 and the upper inner wall of the casing 2, and a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com