Relief for forming layer

A convex and tiny technology, applied in applications, coatings, printing plates, etc., can solve the problems that the organic light-emitting layer 22 is too thin, it is difficult to print, and it is difficult to print highly fine patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

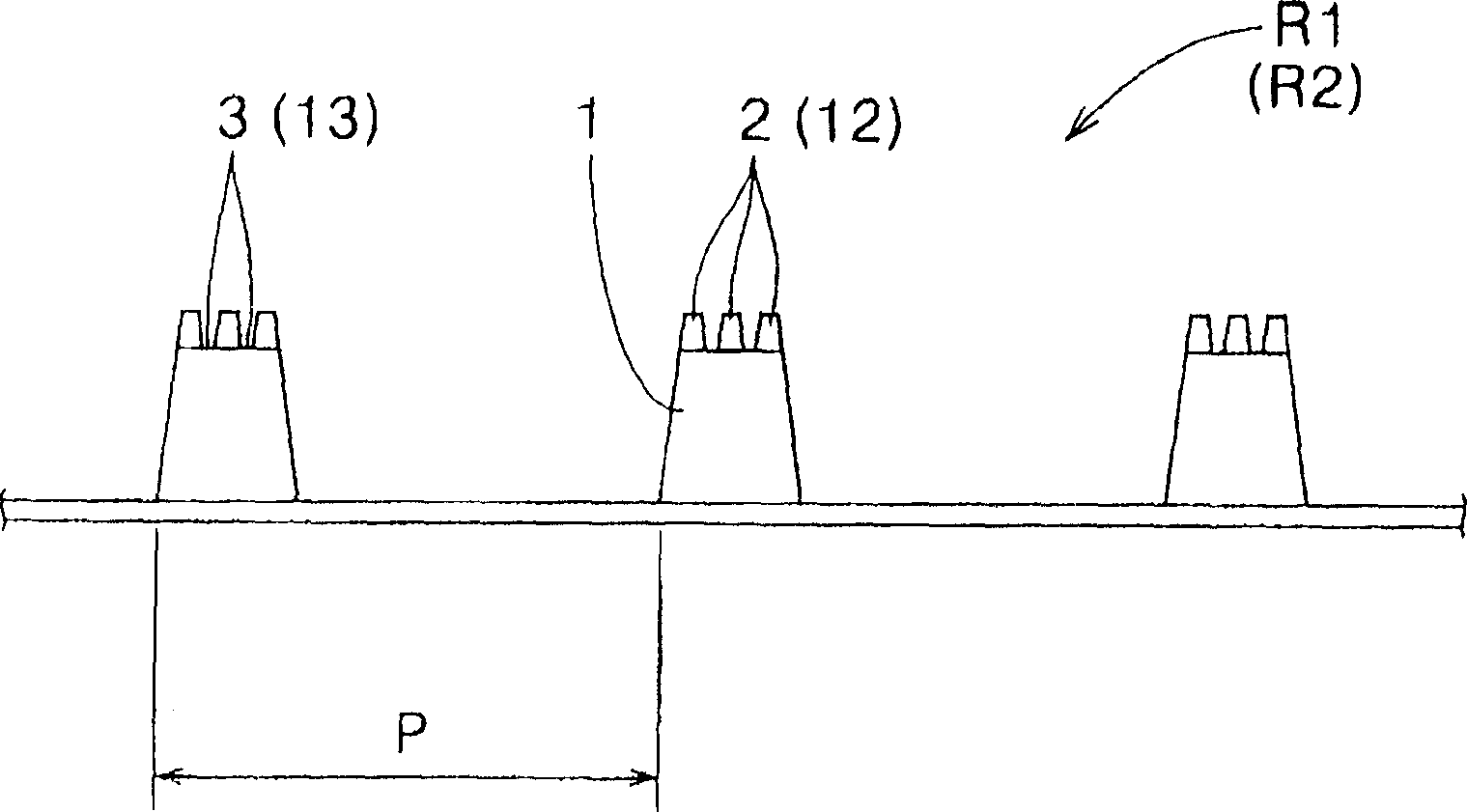

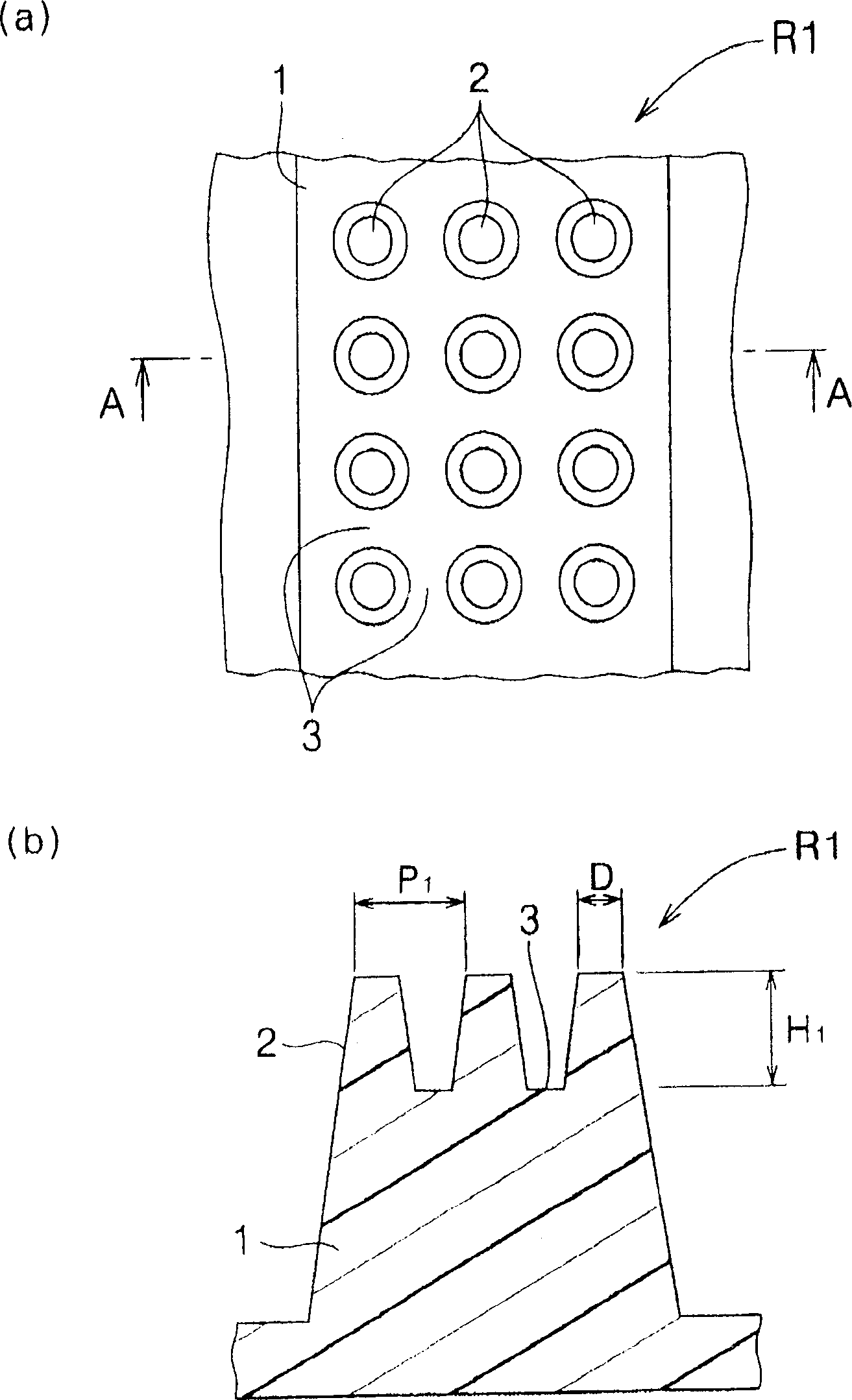

[0041] Prepare a representation such as figure 1 The indicated layer is formed with relief R1. This relief plate R1 for layer formation was manufactured in the same manner as above using liquid photocurable resin (manufactured by Asahi Kasei Co., Ltd.) 7 as a material. In addition, the dimensions of the microprotrusions 2 and the like of the relief plate R1 for layer formation are set as follows.

[0042] · Micro protrusion 2: height H 1 =15μm

[0043] Top surface diameter D=15μm

[0044] Pitch P between adjacent tiny protrusions 2 1 =27.5μm

[0045] The number of micro-protrusions 2 formed in the width direction of the top surface of each printing convex portion 1 = 3

[0046] Total stripe width = 70 μm (= 27.5 × 2 + 15)

[0047] ・Protrusion 1 for printing: installation pitch P=300μm

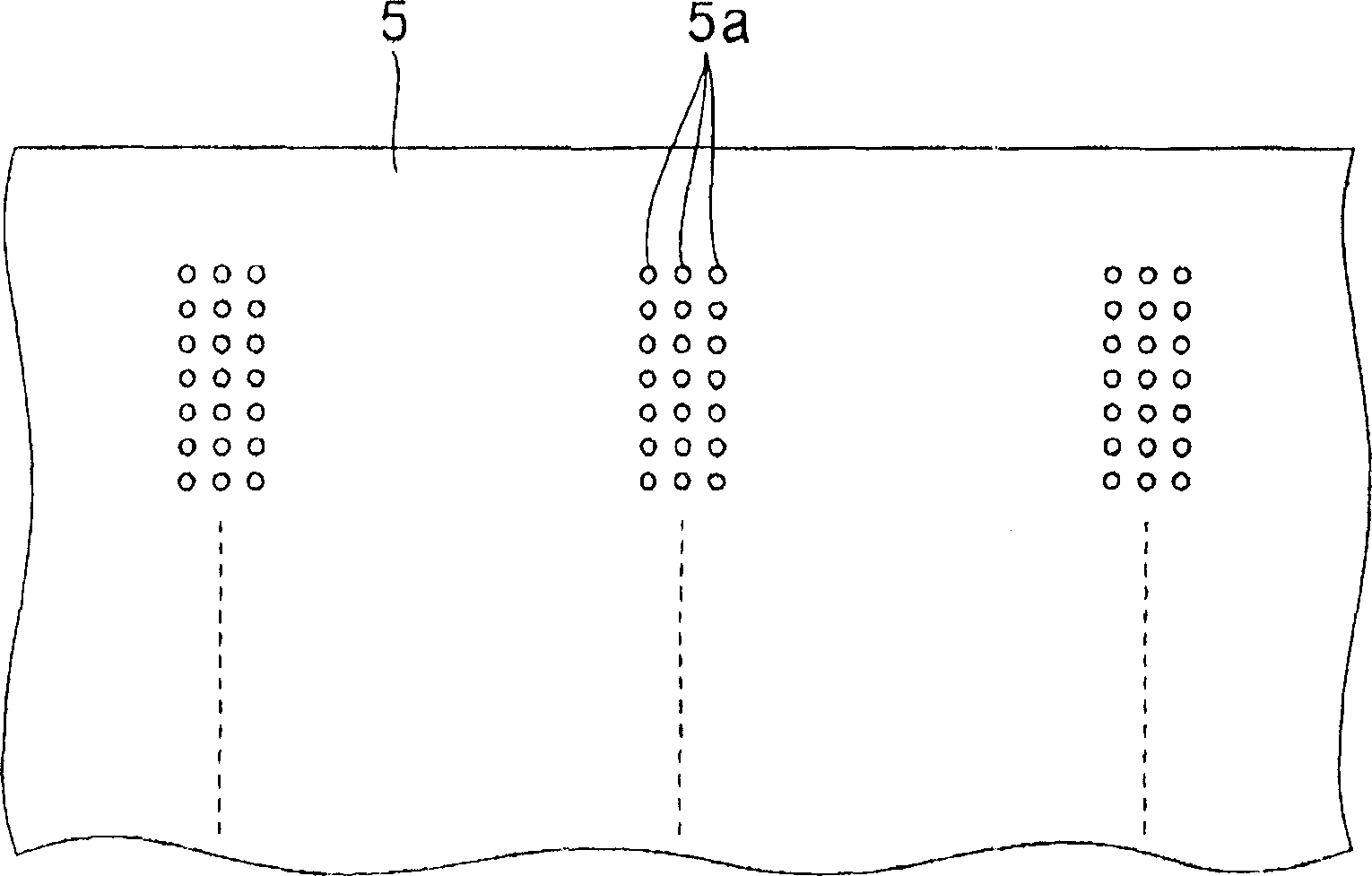

[0048] prepare a Figure 5 The indicated printing machine (manufactured by Nippon Photo Printing Machine Co., Ltd.). The metal ink roller 32 of this printing machine is made into 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com