Back light module, light conducting plate and manufacturing method thereof

A manufacturing method and technology for a backlight module, which are applied in optics, optical components, nonlinear optics, etc., can solve the problems of limiting the tonnage of mold holding pressure, and achieve the effects of reducing assembly complexity, increasing brightness, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

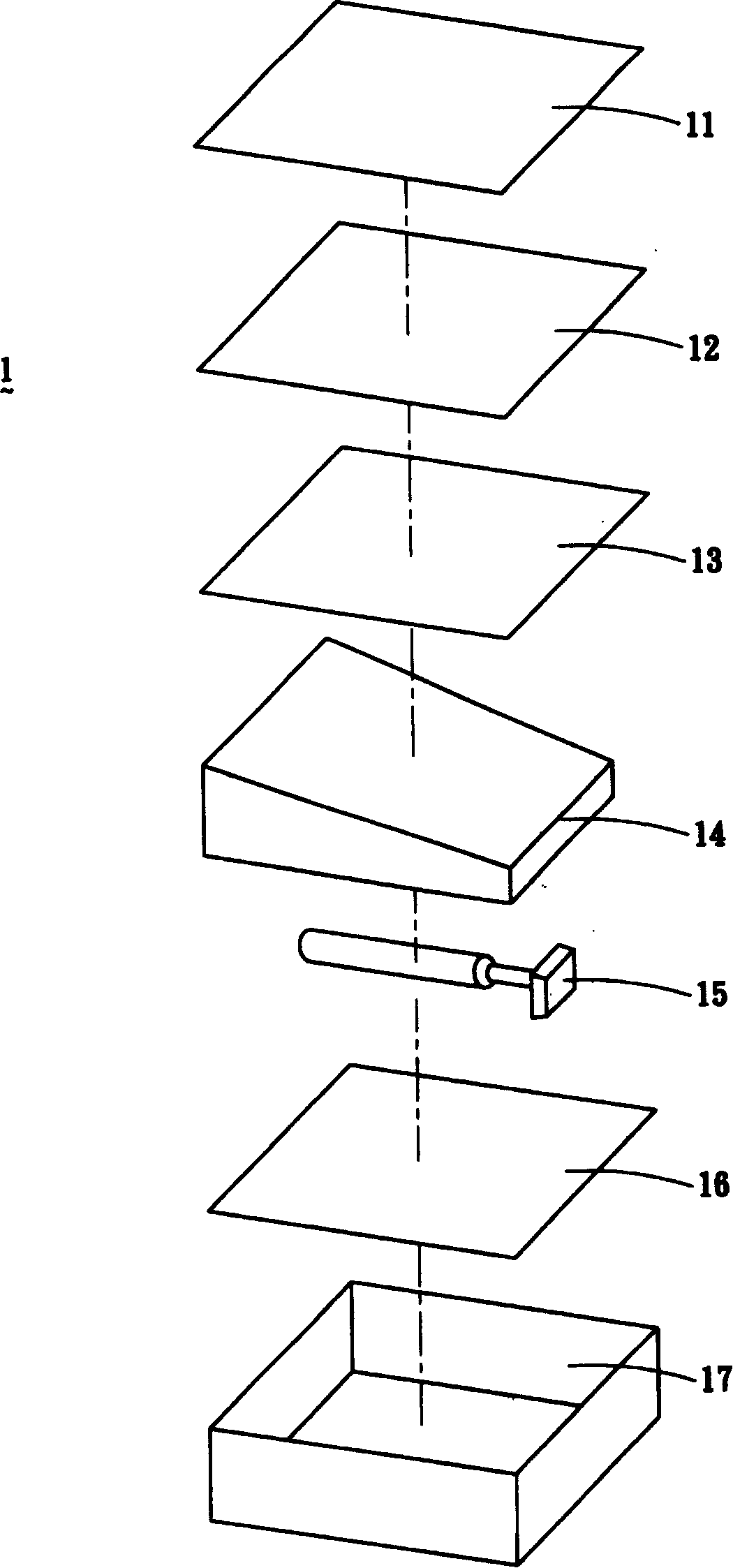

[0037] The light guide plate, the backlight module and the manufacturing method thereof according to the preferred embodiments of the present invention will be described below with reference to related drawings.

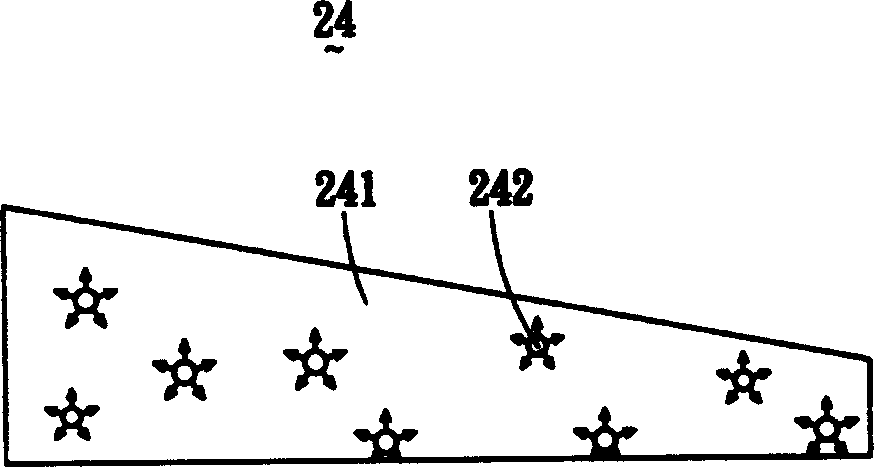

[0038] Such as figure 2 As shown, the light guide plate 24 of the preferred embodiment of the present invention is composed of a light guide substrate 241 and a plurality of diffusion particles 242 . In this embodiment, the light guide substrate 241 can be made of optical acrylic resin or polycarbonate substrate. The diffusion particles 242 can be made of various organic and inorganic materials such as silicon dioxide, titanium dioxide, acrylic resin, polystyrene, silica gel, epoxy resin or polyurethane, or two or more of them. The particle size is between 5 μm and 15 μm, and its proportion in the light guide plate 24 is between 0.5% and 5%. related.

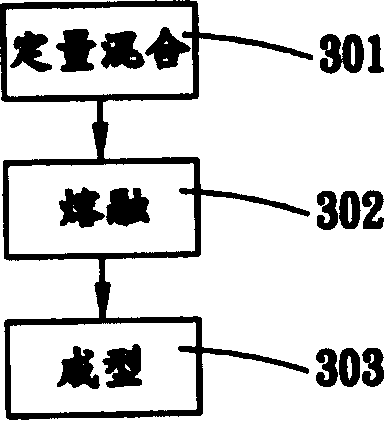

[0039] Also, the manufacturing process of the light guide plate 24 of the preferred embodiment of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com