Infrared permeating oxide fluoride glass

An oxyfluoride, infrared-transmitting technology, applied in the field of chemical composition of fluoroaluminate glass, can solve the problems of difficulty in obtaining fluoroaluminate glass with a thickness, and the anti-devitrification performance of glass has not been fundamentally improved, and achieves good chemical composition. Stability, good glass-forming properties, good glass-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

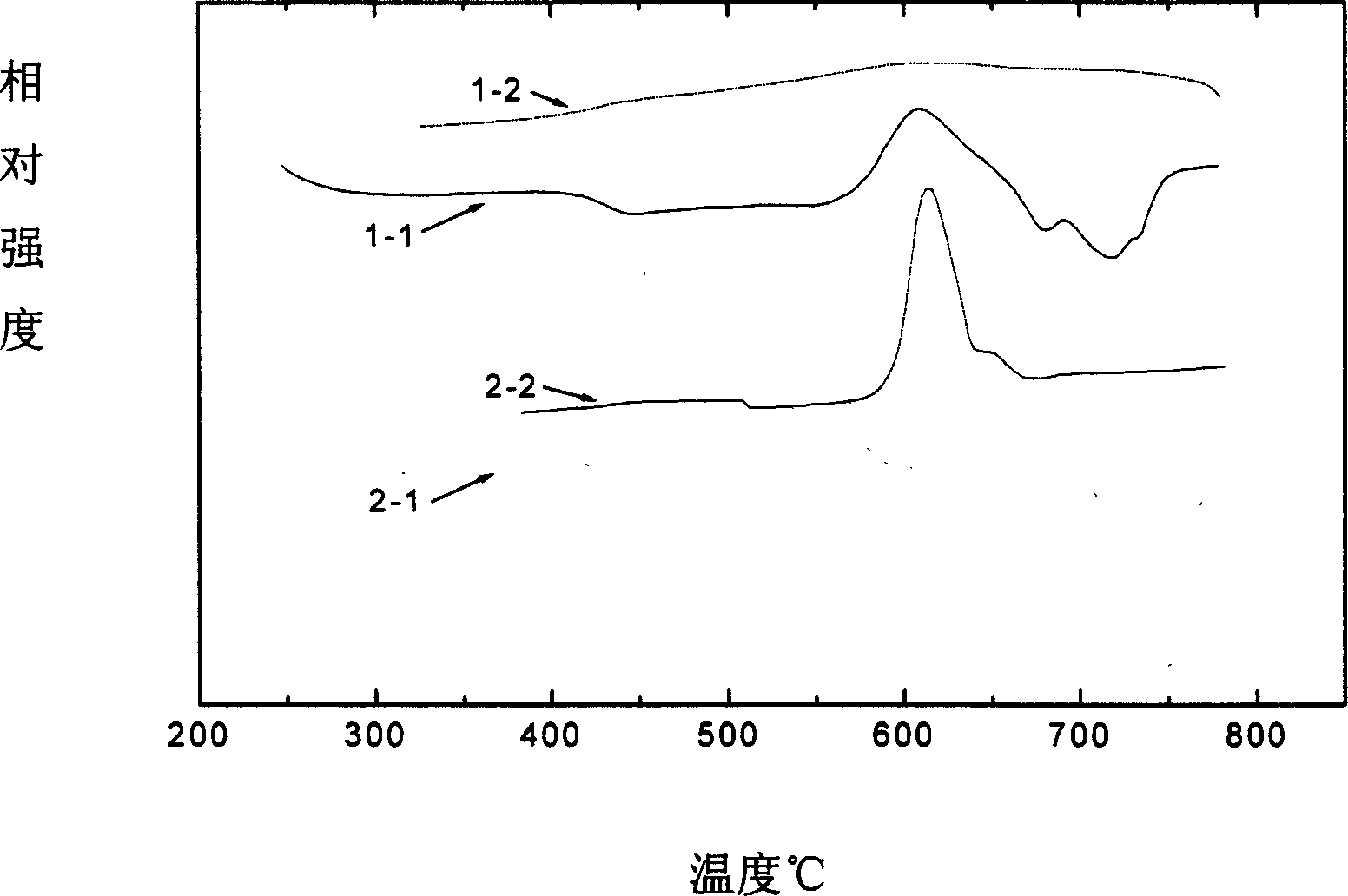

[0027] figure 1 Respectively, the differential thermal ("DTA") heating and cooling curves of pure fluoroaluminum glass (AF) and glass obtained in the present invention (AFT). 1-1 is the AF heating curve; 1-2 is the AF cooling curve; 2-1 is the AFT heating curve; 2-2 is the AFT cooling curve. Comparing 1-2 and 2-2, it can be seen that the pure fluorine-aluminum glass has obvious crystallization peaks in the process of heating up and cooling down of the melt. However, the crystallization peak of the glass obtained in the present invention becomes flat during the heating process, and there is no obvious crystallization peak in the melt cooling process, which shows that the glass composition of the present invention has better glass-forming properties and is suitable for making large-scale materials. .

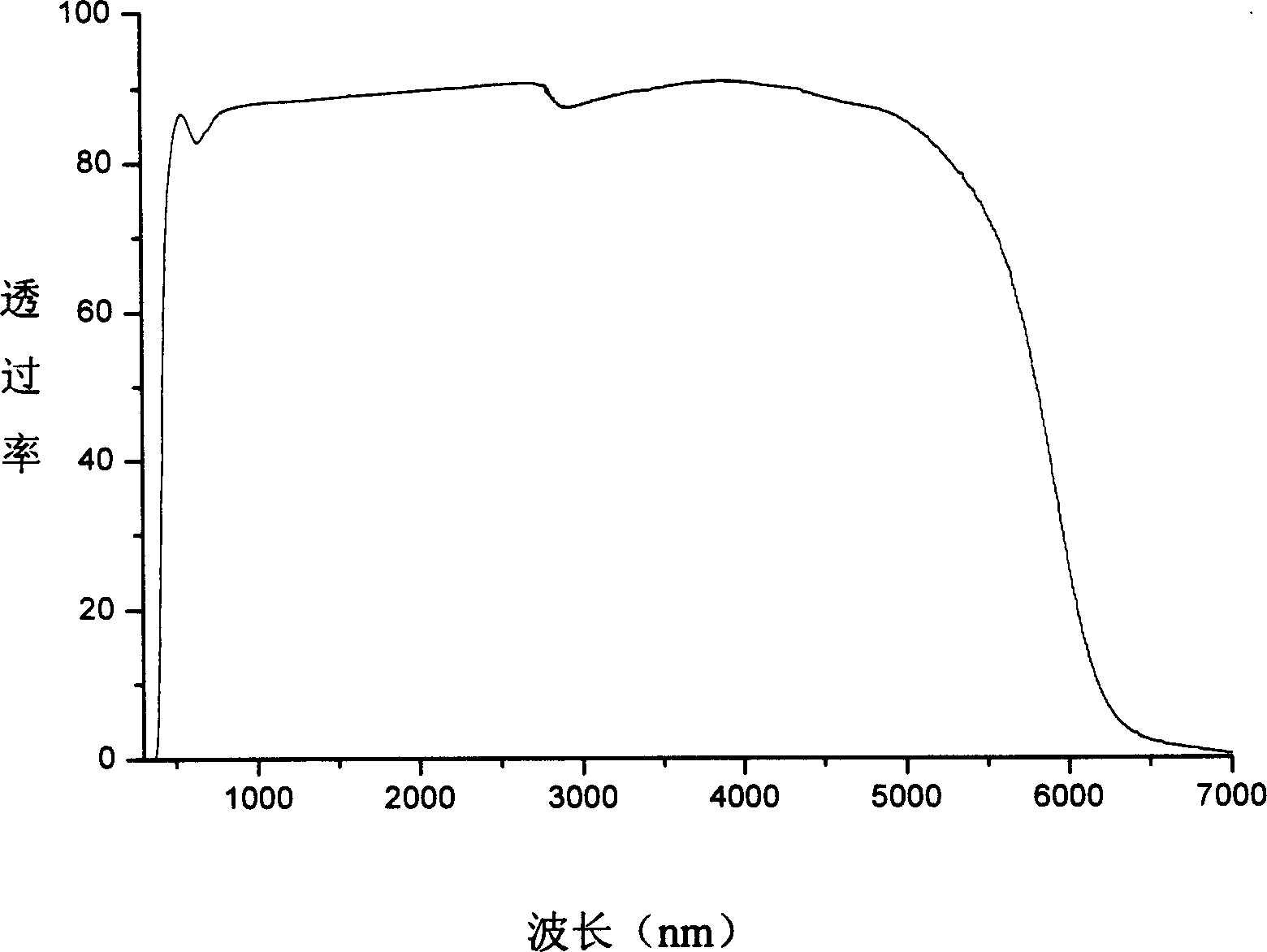

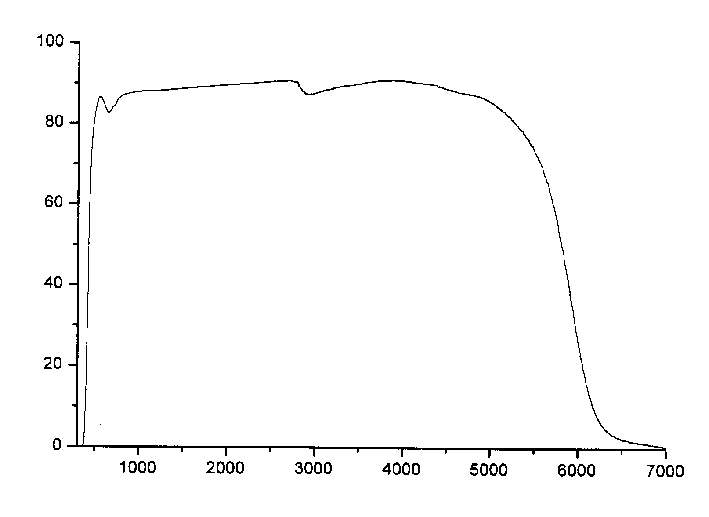

[0028] figure 2 It is the transmittance curve of the large-size glass obtained in the present invention in the near-ultraviolet to mid-infrared band, and the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com