Microwave door with viewing window

A technology of microwave devices and windows, applied in the direction of microwave heating, electric heating devices, applications, etc., can solve the problems that cannot be realized optimally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

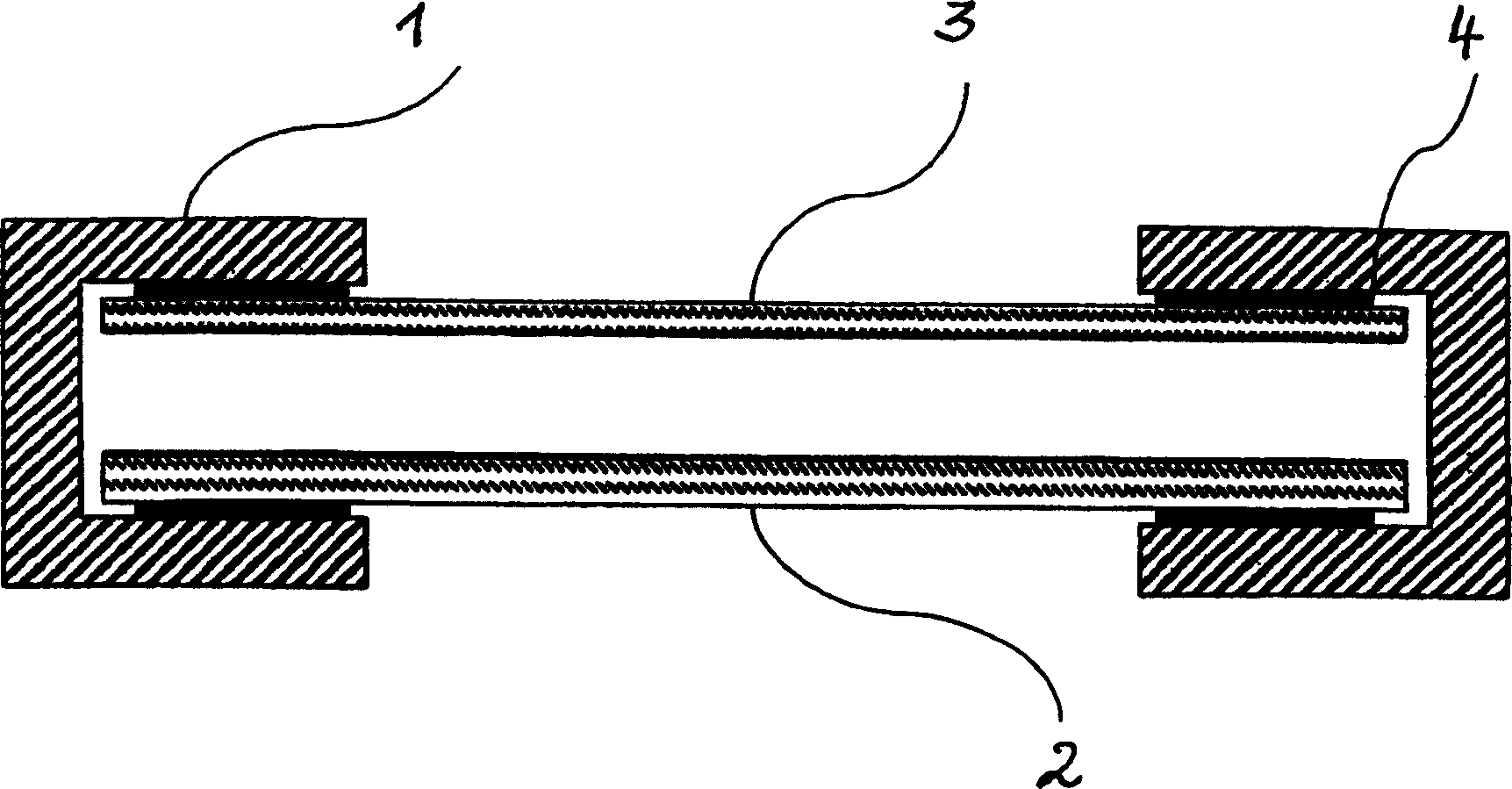

[0026] The windowed door for a microwave device shown in the figures has a metal frame 1 in which two glass panes 2, 3 are fastened spaced apart. The glass plate 3 facing the inside of the device is preferably made by the trademark Borofloat glass, while the glass pane 2 facing the surroundings is preferably made of the trademark "Scholf The glass panes 2, 3 are preferably glued to the metal frame 1 by means of an adhesive 4. The adhesive 4 thus ensures that the glass panes 2, 3 are inserted in a professional manner, i.e. The glass pane is supported continuously elastically and shock-absorbing.

[0027] The glass plate 3 directed towards the inside of the cooking chamber has at least one first layer that is optically transparent and absorbs microwave radiation, the absorption capacity of which is designed such that it heats up to prevent the formation of condensation water.

[0028] The first layer can be formed, for example, by a high-resistance conductive layer having ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com