Method for establishing mixed expert system of maintaining cigarette leaf group formulation

A leaf group formula, mixing expert technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of not guaranteeing the fluctuation range of the new leaf group, unable to fully balance the sensory evaluation and smoke analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

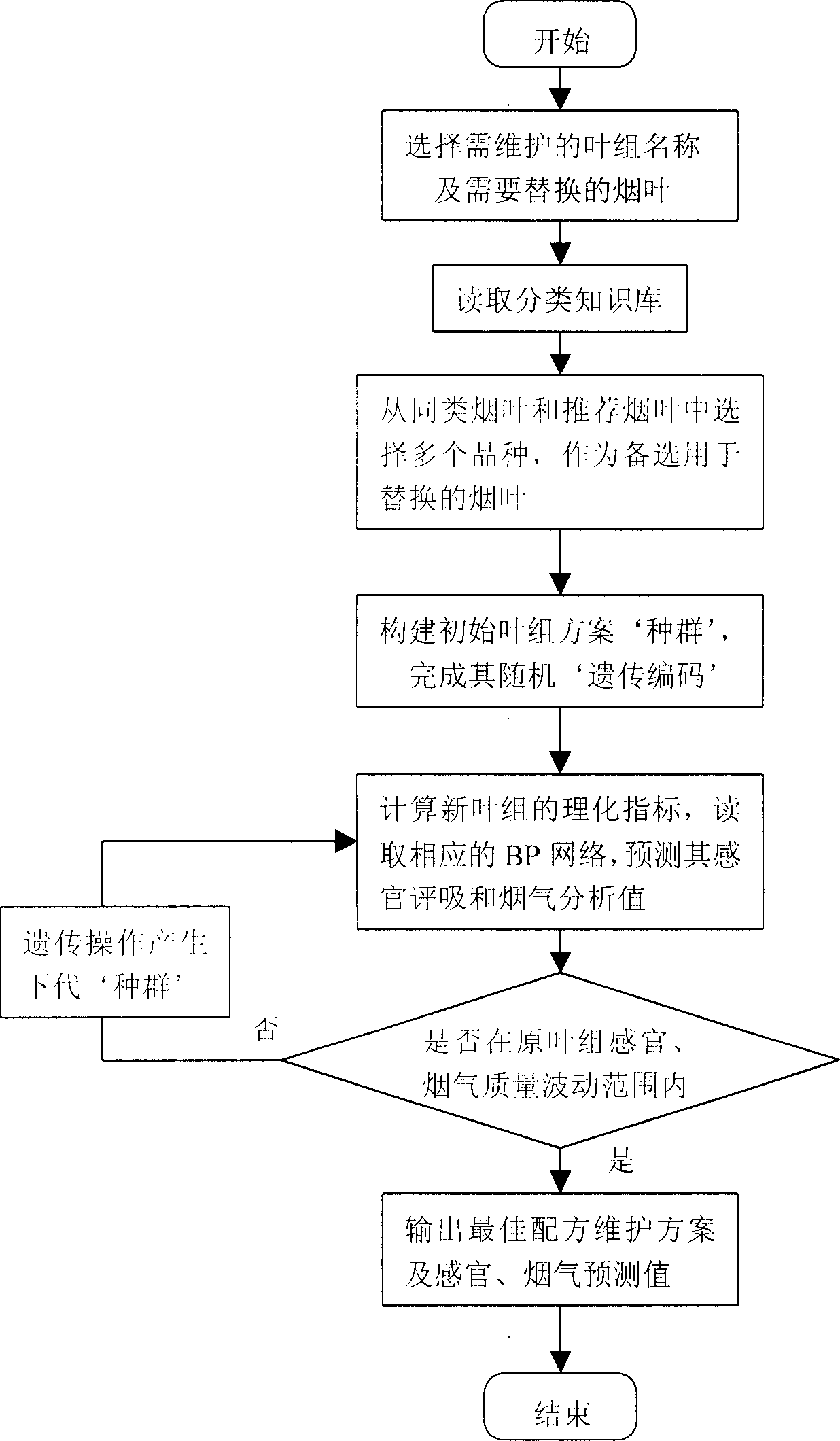

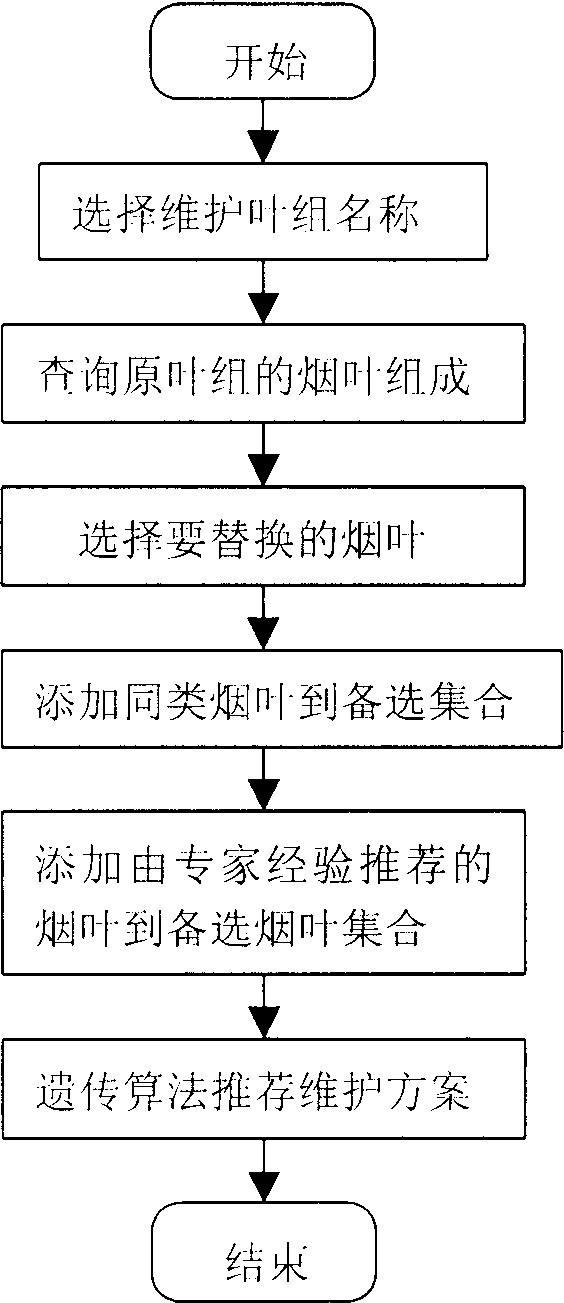

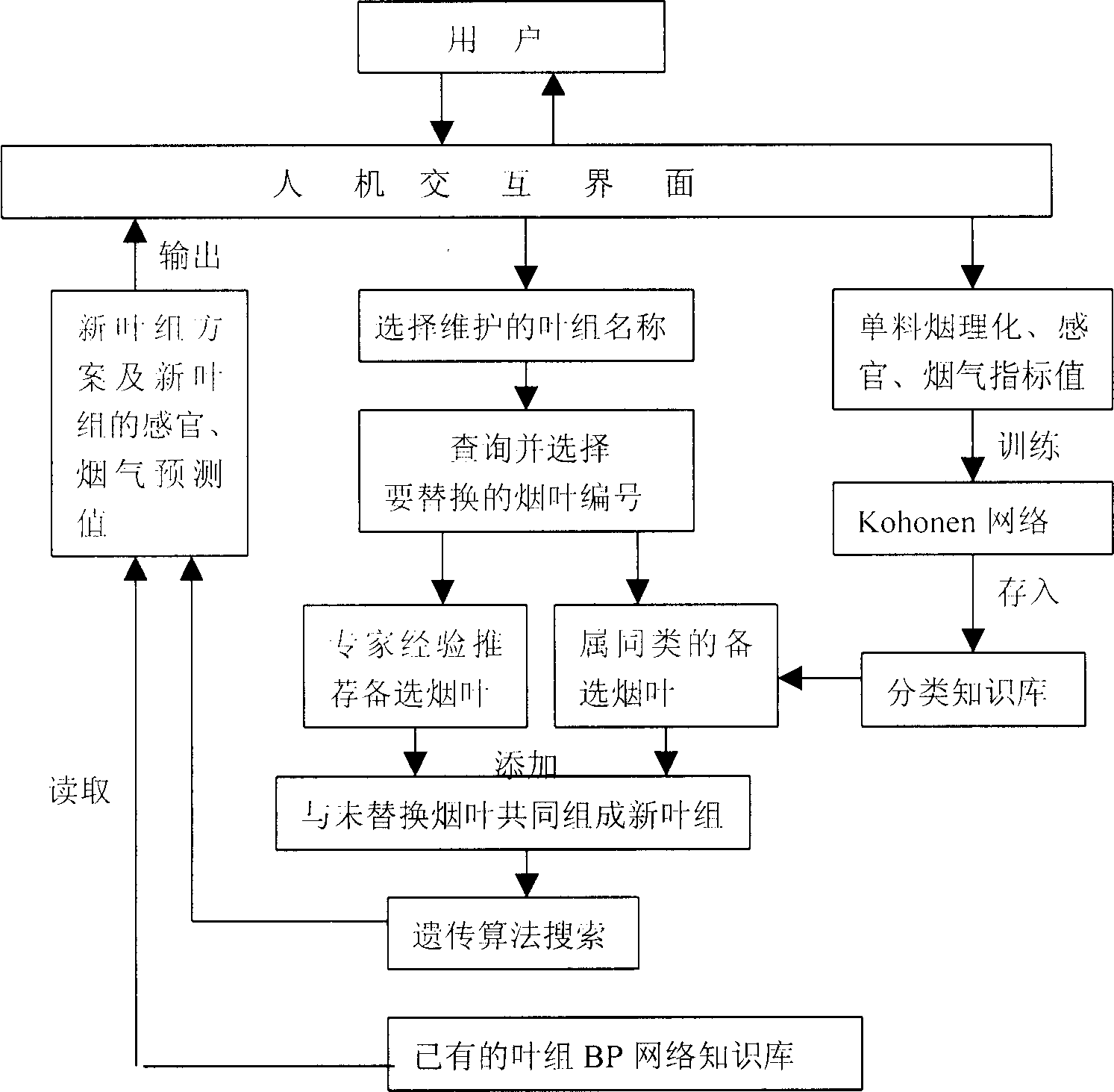

[0018] The process of the present invention for establishing the intelligent leaf group formula maintenance system is as follows: figure 1 and 3 As shown, the steps are as follows:

[0019] (1) First, the sample data is grouped by style according to the experience of industry experts, and then according to the physical and chemical analysis (including gas chromatography analysis), sensory evaluation (sensory test) and smoke analysis index data of the tobacco leaves in each group, self-organization through the Kohonen network Clustering to obtain multi-category tobacco leaf collections;

[0020] (2) Select the name of the leaf group formula to be maintained, and inquire about the tobacco leaf composition of the original leaf group;

[0021] (3) According to production needs, determine the tobacco leaves to be replaced in the leaf group, read the information of each set to which each replaced tobacco leaf belongs, and recommend it to the user. On this basis, the user selects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com