Method for producing plastic components

A technology of plastic parts and plastics, which is applied in the field of manufacturing plastic parts and can solve problems such as labor and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

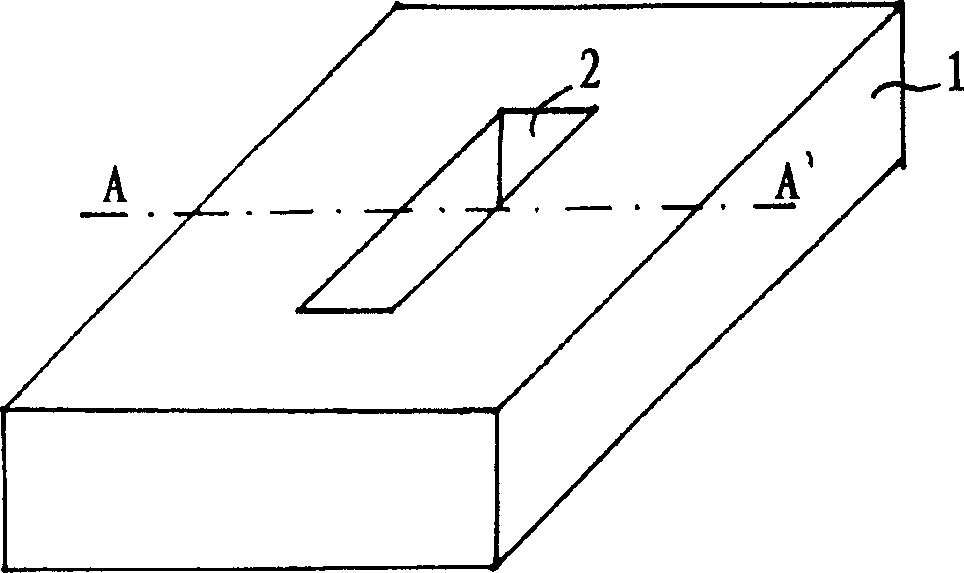

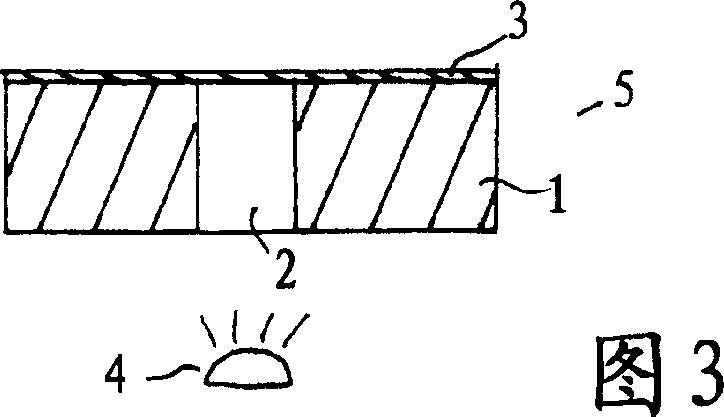

[0013] The first step of the present invention is to form by injection molding such as figure 1 The blank shown in 1. This blank can take any desired shape; it is an opaque plastic part, preferably black, with a recessed space 2 forming a mark or symbol in plan view, which is the translucent area on the front face, It can be seen on a display panel or cover or similar when it is illuminated. The recessed space 2 extends vertically completely through the blank from an opening on the front surface of the blank.

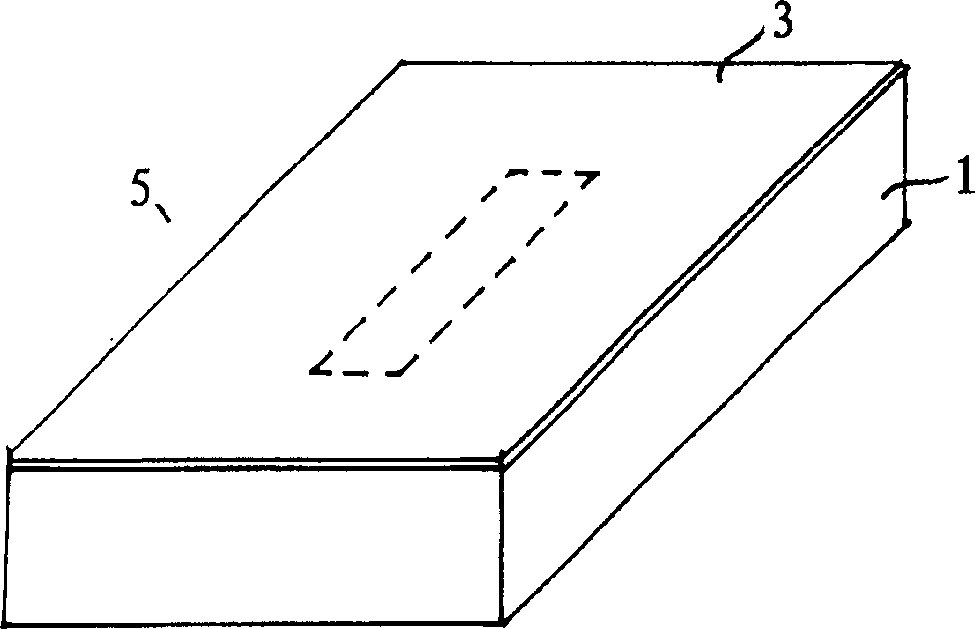

[0014] figure 2 The second step performed by the method according to the invention is shown. This second step can be carried out in the same mold as the previous step or in another mold. A thin layer 3 of the second plastic part is molded onto the surface of the blank 1 . This layer is very thin so it is translucent. Its color can be chosen so as to closely match the surrounding colors. It spans the opening in the surface of the blank. These two plastic parts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com