Graded porous nano alumina/gold composite film electrode and preparation method thereof

A technology of nano-alumina and composite thin films, which is applied in the direction of material electrochemical variables, metal material coating technology, ion implantation plating, etc., to achieve high electrocatalytic activity, high electron transfer efficiency, and good detection sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

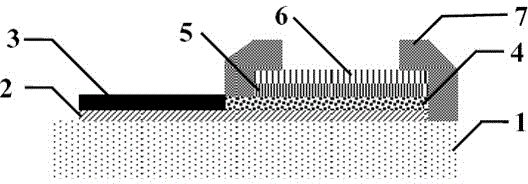

[0019] 1. Preparation of multilayer composite films

[0020] a. Use quartz as the insulating substrate. After thorough cleaning, dry it with nitrogen gas, and use magnetron sputtering to deposit the first bonding layer titanium layer on the insulating substrate with a thickness of 50 nm;

[0021] b. Using magnetron sputtering, a gold layer is deposited on the surface of the titanium layer of the first bonding layer, with a thickness of 120 nm;

[0022] c. Using magnetron sputtering, deposit a quasi-second bonding layer titanium layer at one end of the surface of the gold layer 7, with a thickness of 30 nm;

[0023] d. Depositing an aluminum layer with a thickness of 1000 nm on the quasi-second bonding layer titanium by thermal evaporation;

[0024] e. Using magnetron sputtering, deposit a silicon dioxide layer on the edge of the composite film with a thickness of 1300 nm;

[0025] 2. Anodizing multilayer films

[0026] f. Using an oxalic acid solution with a concentration...

Embodiment 2

[0034] 1. Preparation of multilayer composite films:

[0035] a. Use glass as the insulating substrate. After thorough cleaning, dry it with nitrogen gas, and use magnetron sputtering to deposit the first bonding layer of tantalum on the insulating substrate with a thickness of 80nm;

[0036] b. Using magnetron sputtering, a gold layer is deposited on the surface of the tantalum layer of the first bonding layer, with a thickness of 180nm;

[0037] c. Using magnetron sputtering, deposit a quasi-second bonding layer tantalum layer at one end of the gold layer surface, with a thickness of 40nm;

[0038] d, using thermal evaporation to deposit an aluminum layer on the quasi-second bonding layer tantalum layer, with a thickness of 2500nm;

[0039] e. Using magnetron sputtering, deposit a silicon dioxide insulating layer on the edge of the composite film layer, with a thickness of 2900 nm;

[0040] 2. Anodizing multilayer films

[0041] f. Using a phosphoric acid solution with ...

Embodiment 3

[0046] 1. Preparation of multilayer composite films:

[0047] a. Using a silicon wafer with silicon dioxide as the insulating substrate, after thorough cleaning, dry it with nitrogen, and use magnetron sputtering to deposit the first bonding layer of niobium on the insulating substrate with a thickness of 5 nm;

[0048] b. Using magnetron sputtering, a gold layer is deposited on the surface of the niobium layer of the first bonding layer, with a thickness of 80 nm;

[0049] c. Using magnetron sputtering, deposit a quasi-second bonding layer niobium layer at one end of the gold layer surface, with a thickness of 5 nm;

[0050] d. Depositing an aluminum layer with a thickness of 300 nm on the quasi-second bonding layer by magnetron sputtering;

[0051] e. Spin-coating process is used to cover SU-8 layer along the edge of the composite film layer, with a thickness of 400 nm;

[0052] 2. Anodizing multilayer films

[0053] d. Using a sulfuric acid solution with a concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com