Leakage checking up device for evaporation fuel purifying system

A technology for purifying system and evaporating fuel, applied in charging system, measuring device, condensed fuel collection/return, etc., can solve problems such as damage to leak detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] (first embodiment)

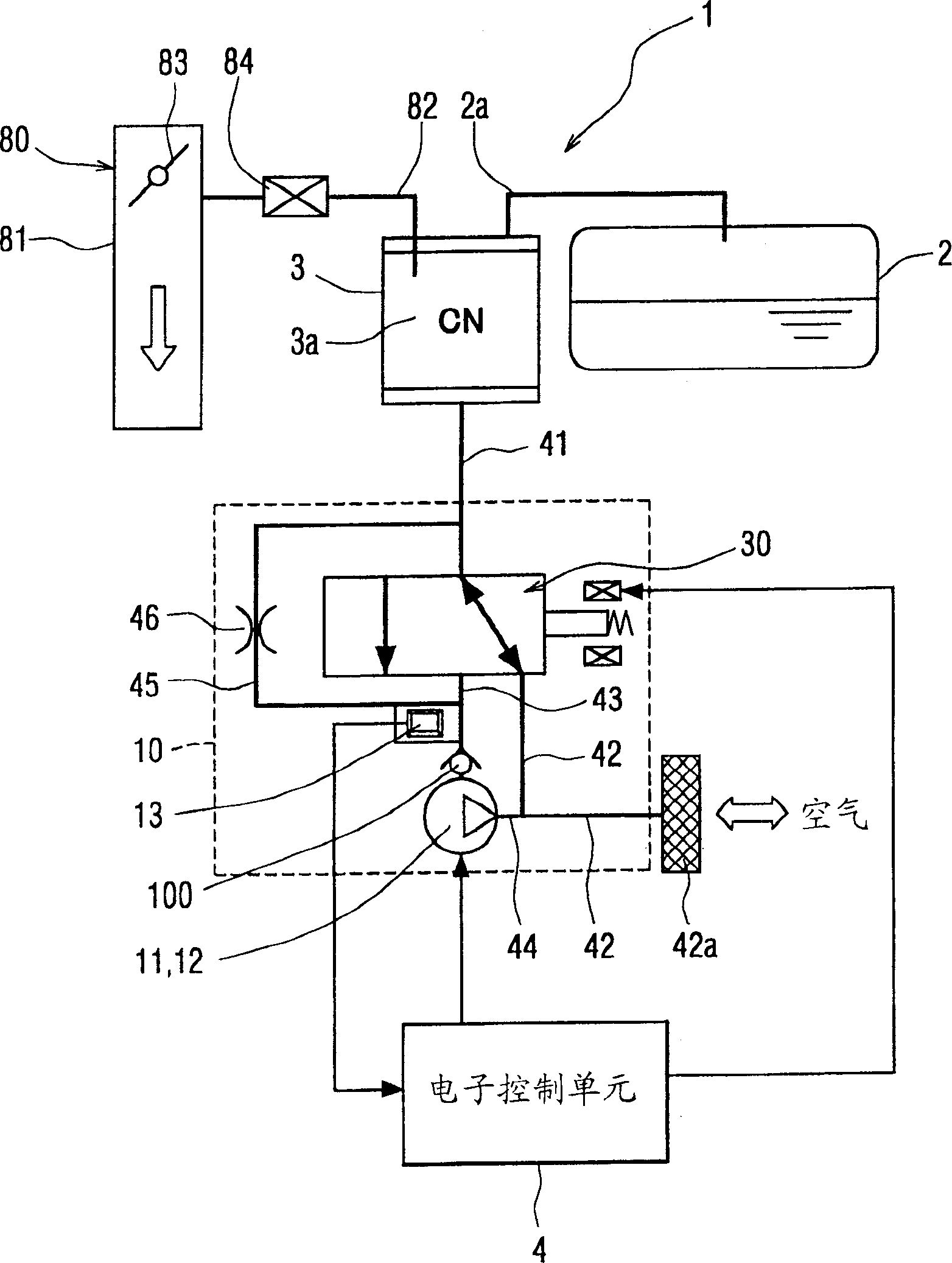

[0036] Such as figure 1 As shown, the evaporative fuel purification system includes a fuel tank 2, a canister 3 as an absorption filter connected to the fuel tank 2 through a connecting fluid passage 2a and having a ventilation fluid passage 41, and a purge control valve 84 as a ventilation valve. One end of the ventilation valve 84 is connected to the canister 3 through the valve fluid passage 82 , and the other end of the ventilation valve 84 is connected to the intake system 80 of the internal combustion engine through the valve fluid passage 82 . The canister 3 contains an adsorbent 3a such as activated carbon.

[0037] A part of the fuel held in the fuel tank 2 evaporates, and the evaporated fuel is generated in the fuel tank 2 . This evaporated fuel is guided into the canister 3, where it is temporarily absorbed and accumulated. When purge control valve 84 is opened by air due to the reduced pressure in suction system 80 , air is drawn thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com