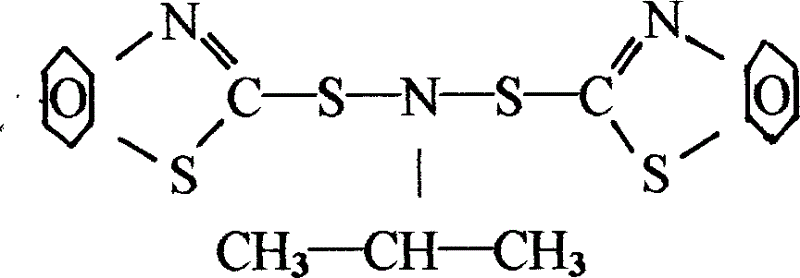

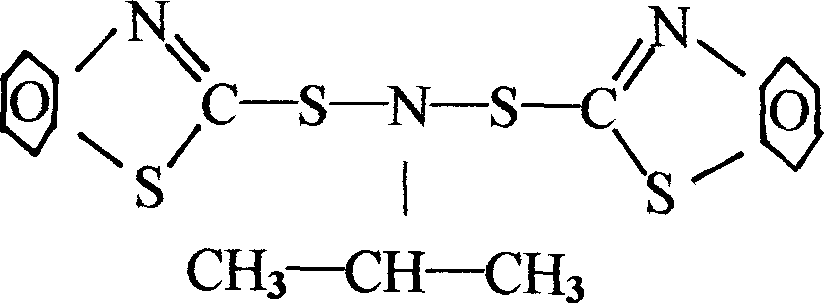

N-tert-butyl-2 (benzothiazyl) sulfenamide and production process thereof

A technology of benzothiazole and sulfenamide, which is applied in the direction of organic chemistry, etc., can solve the problems of poor scorch resistance and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] N-tert-butyl-bis(benzothiazole)sulfenamide of the present invention has passed small-scale test,

[0013] In a small test: take NS and maleic anhydride in a ratio of 1:0.5mol;

[0014] It is carried out according to the following steps:

[0015] (1), take the raw materials NS and maleic anhydride, add them to the synthesis reaction ax in the ratio of 1:0.5mol and stir, add 120 # Solvent oil, heated up to 90°C, reacted for 40 minutes;

[0016] (2) The above-mentioned synthetic raw materials are cooled to room temperature, neutralized to neutral with 5% aqueous sodium hydroxide solution, washed with water, filtered, dried, pulverized, and packaged as a finished product.

[0017] The small-scale test product of N-tert-butyl-bis(benzothiazole)sulfenamide TBSI of the present invention has been tested by the State Key Laboratory of Metal Matrix Composite Materials of Shanghai Jiaotong University, and the test items are: characteristic curve of vulcanizer, hardness, tensile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com