High-pressure mud pump sandwiching concrete piston and its manufacturing method

A technology of mud pumps and concrete pistons, which is applied in the field of cloth-filled concrete pistons for sealing high-pressure mud pumps used in construction machinery and its manufacturing field, which can solve the problems of frictional noise hazards between pistons and cylinders, poor high temperature resistance, and short service life. Achieve the effect of enhancing pressure resistance, improving wear resistance and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

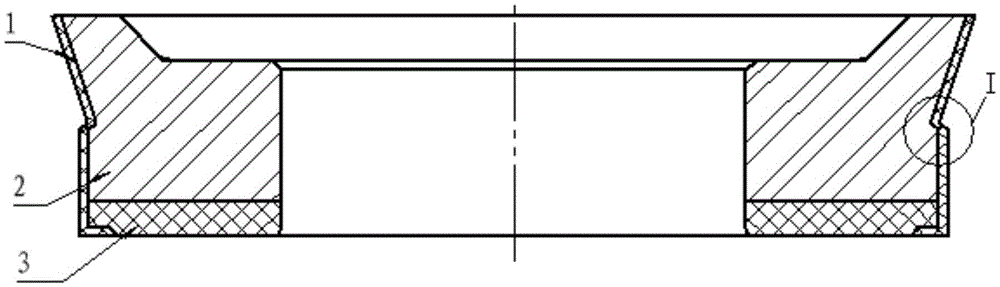

[0046] Such as figure 1 As shown, the high-pressure mud pump is sandwiched with a concrete piston, and the content ratio of each raw material component is as follows in parts by weight:

[0047] Carboxylated nitrile rubber 100 parts,

[0048] ZnO5 parts,

[0049] SA0.5 copies,

[0050] Anti-aging agent 1 part,

[0051] 40 parts of carbon black,

[0052] 3 parts softener,

[0053] 0.2 parts of sulfur,

[0054] Accelerator 4 parts;

[0055] The anti-aging agent is RD, the softener is DO, and the accelerator is TMTD;

[0056] And it is prepared by the following steps:

[0057] The first step, synthetic rubber: the above raw materials are synthesized into rubber through an internal mixer;

[0058] The second step, molding: the synthetic rubber is molded by an open mill;

[0059] The third step, vulcanization: Put the formed rubber into the mold in the vulcanizer, pressurize the range of 150kgf / ㎝2, raise the temperature to 140°C for 30min, and vulcanize.

[0060] The clo...

Embodiment 2

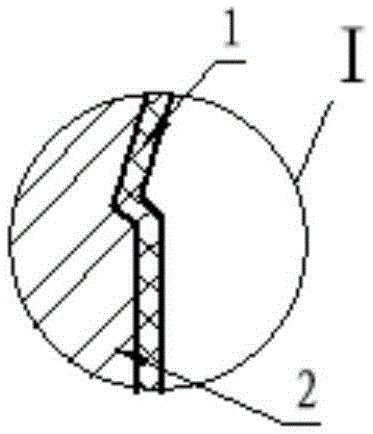

[0076] Such as figure 2 As shown, the high-pressure mud pump is sandwiched with a concrete piston, and the content ratio of each raw material component is as follows in parts by weight:

[0077] Carboxylated nitrile rubber 100 parts,

[0078] ZnO8 parts,

[0079] SA1 copy,

[0080] Anti-aging agent 2 parts,

[0081] 50 parts of carbon black,

[0082] 5 parts softener,

[0083] 0.5 parts of sulfur,

[0084] Accelerator 6 parts;

[0085] The anti-aging agent is MB, the softener is DOS, and the accelerator is DM;

[0086] And it is prepared by the following steps:

[0087] The first step, synthetic rubber: the above raw materials are synthesized into rubber through an internal mixer;

[0088] The second step, molding: the synthetic rubber is molded by an open mill;

[0089] The third step, vulcanization: put the shaped rubber into the mold of the vulcanizer, pressurize the range of 210kgf / ㎝2, raise the temperature to 150°C for 45min, and vulcanize.

[0090] The cloth-cl...

Embodiment 3

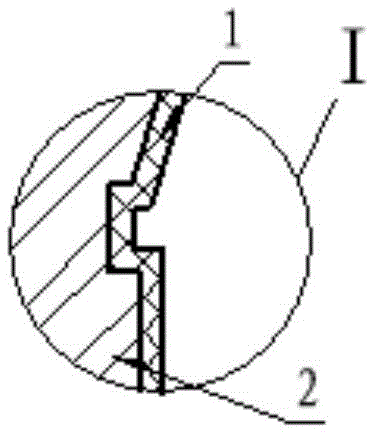

[0106] like image 3 As shown, the high-pressure mud pump is sandwiched with a concrete piston, and the content ratio of each raw material component is as follows in parts by weight:

[0107] Carboxylated nitrile rubber 100 parts,

[0108] ZnO6.5 parts,

[0109] SA0.75 parts,

[0110] Anti-aging agent 1.5 parts,

[0111] 45 parts of carbon black,

[0112] softener 4 parts,

[0113] 0.35 parts of sulfur,

[0114] Accelerator 5 parts;

[0115] The anti-aging agent is 4010NA, the softener is DOA, and the accelerator is BZ;

[0116] And it is prepared by the following steps:

[0117] The first step, synthetic rubber: the above raw materials are synthesized into rubber through an internal mixer;

[0118] The second step, molding: the synthetic rubber is molded by an open mill;

[0119] The third step, vulcanization: put the molded rubber into the mold of the vulcanizer, pressurize the range of 180kgf / ㎝2, raise the temperature to 145°C for 37.5min, and vulcanize.

[0120]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com