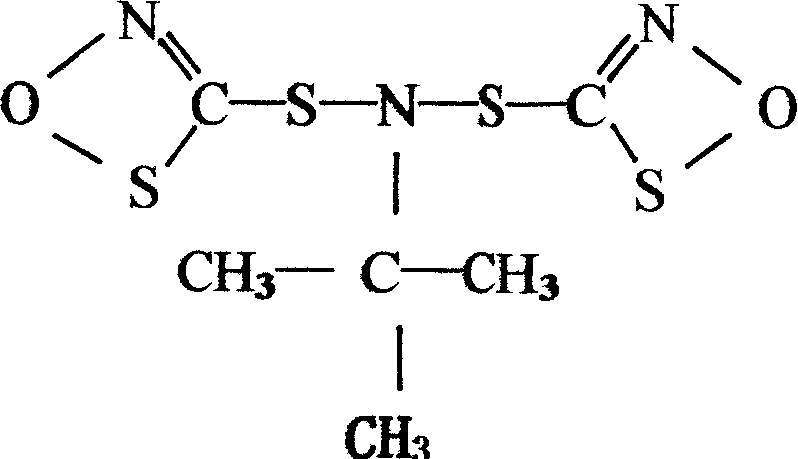

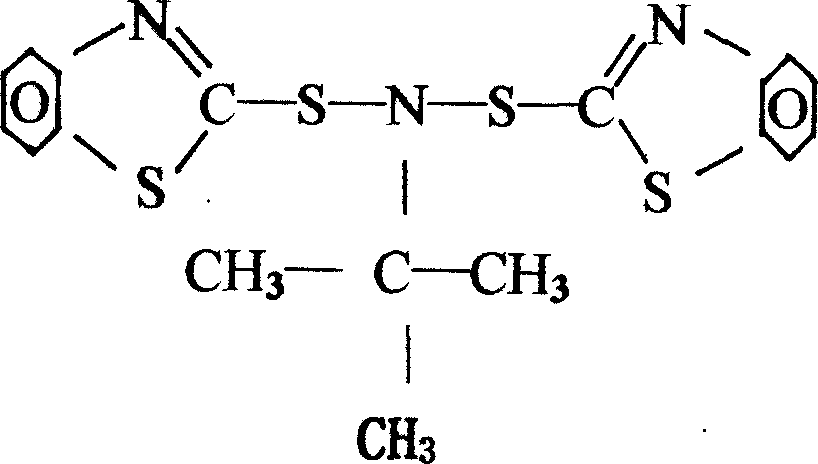

N-teriary-butyl-2 (benzothiazyl) sulfenamide and production process thereof

A technology of benzothiazole sulfenamide and benzothiazole is applied in the field of N-tert-butyl-bissulfenamide and its production technology, and can solve the problems of poor scorch resistance, increased production cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The N-tert-butyl-bis(benzothiazole) sulfenamide of the present invention has passed a small test,

[0012] In a small-scale test: prepare tert-butyl-2-benzothiazole sulfenamide and maleic anhydride in a ratio of 1:0.5mol;

[0013] It is carried out according to the following steps:

[0014] (1) Take the raw materials tert-butyl-2-benzothiazole sulfenamide and maleic anhydride, add them to the synthesis reaction axe at a ratio of 1:0.5 mol, and add 120 in the volume of the material twice. # Solvent oil, heat up to 90°C, react for 40 minutes;

[0015] (2) Cooling the above synthetic raw materials to room temperature, neutralizing them with 5% sodium hydroxide aqueous solution to neutrality, washing, filtering, drying, pulverizing, and packaging the finished product.

[0016] The N-tert-butyl-bis(benzothiazole) sulfenamide TBSI of the present invention is a small-scale test product tested by the State Key Laboratory of Metal Matrix Composites of Shanghai Jiaotong University. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com