Pretightening and endergonic device of safety belt

An energy-absorbing device and seat belt technology, which is applied to seat belts in vehicles, transportation and packaging, vehicle components, etc., can solve the problems of reduced device reliability, complex seat belt structures, and high product prices, and achieve simplified structure and simplification. structure, the effect of increasing the effective stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

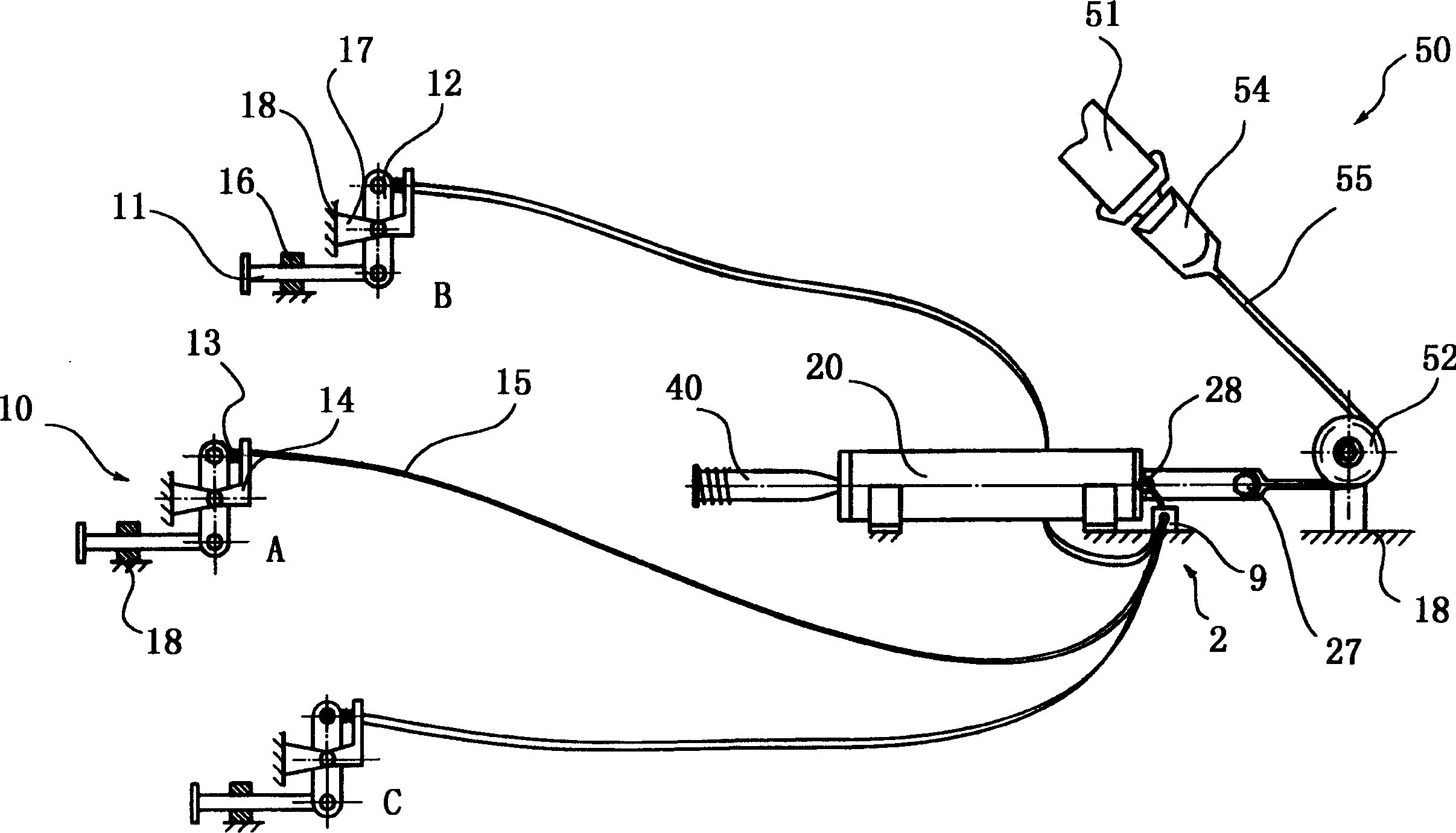

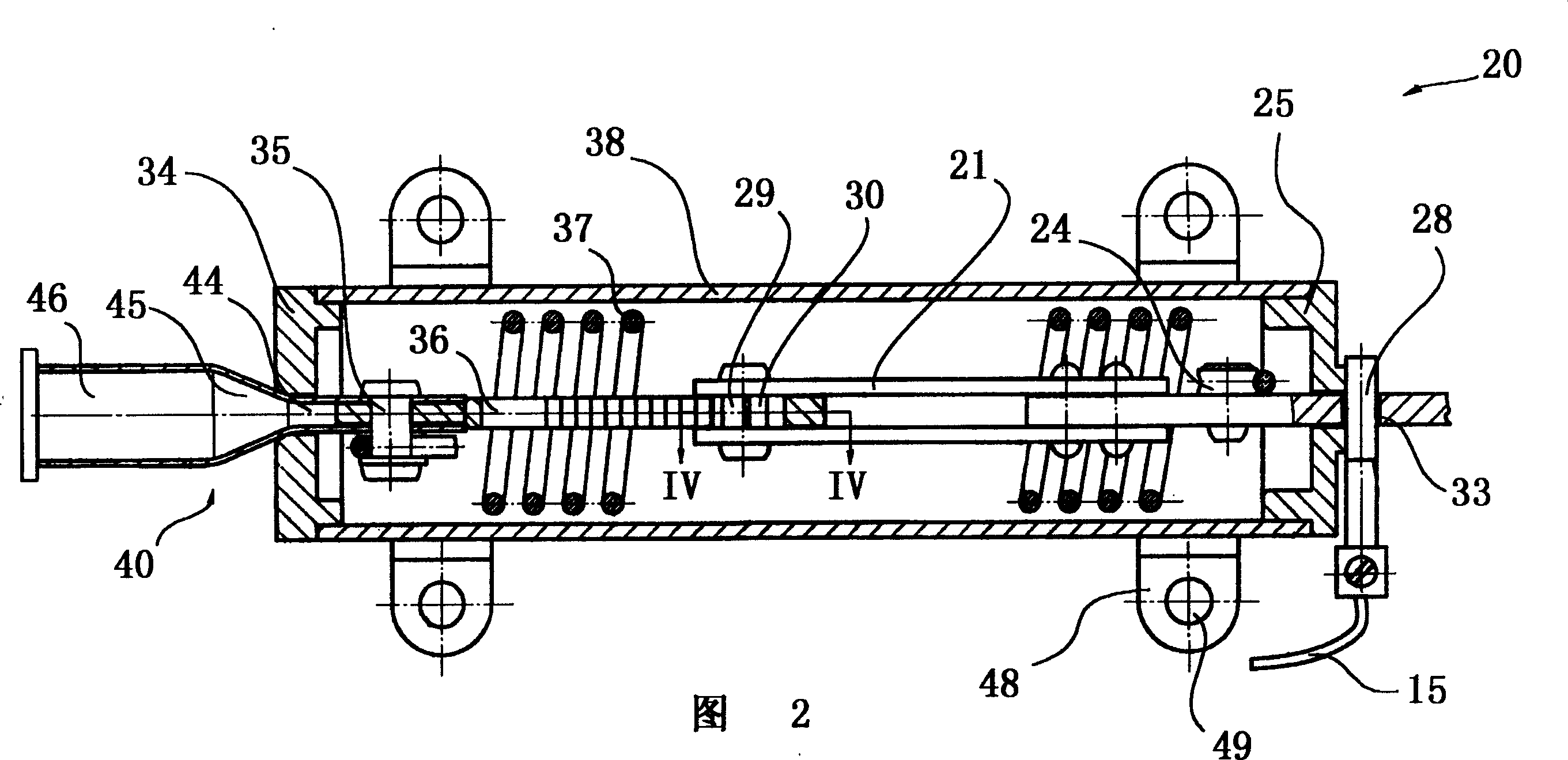

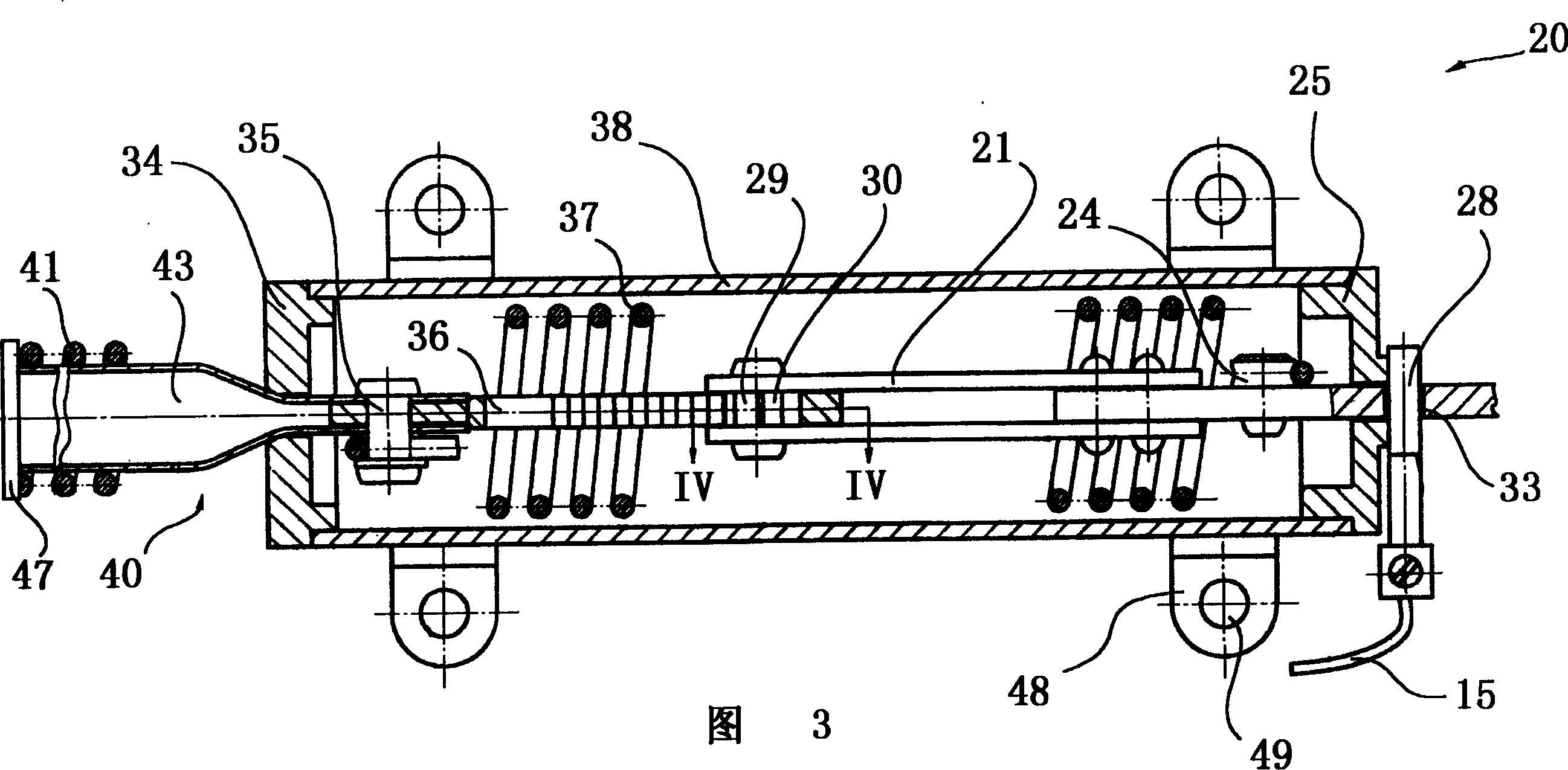

[0040] as attached figure 1 As shown, it depicts a preferred embodiment of the present invention, the seat belt pretensioning and energy absorbing device provided in this embodiment is installed on a car, wherein three contact triggers 10 are depicted, and they are respectively Set on the front and sides of the car. The touch triggers 10 are respectively installed on the frame 18 of the vehicle. The touch trigger 10 is connected to the controller 2 through a cable 15 . In this embodiment, the contact trigger 10 includes a lance element 11, which is movably supported on a lance bracket 16, one end of the lance element 11 is a trigger end, and the other end of the lance element 12 is connected to the lever 12. The first end is hinged. The middle part of the lever 12 is hinged with the lever bracket 17 . The second end of the lever 12 is connected with one end of the cable 15 passing through the limiter 14 and the spring 13 . The other end of the stay cable 15 passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com