Carriage structure of car body

A frame structure and vehicle body technology, applied in the structural field of the connecting part, can solve the problem of not being able to improve the corner strength of the connecting support beam and the upper side beam, and achieve the effects of easy installation, simplified shape, and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Next, the embodiments of the present invention will be described, and the same parts as those of the above-mentioned conventional device and the same parts of the respective embodiments will be given the same reference numerals, respectively. However, the present invention is not limited to the examples described below, and various changes can be made without departing from the gist of the present invention.

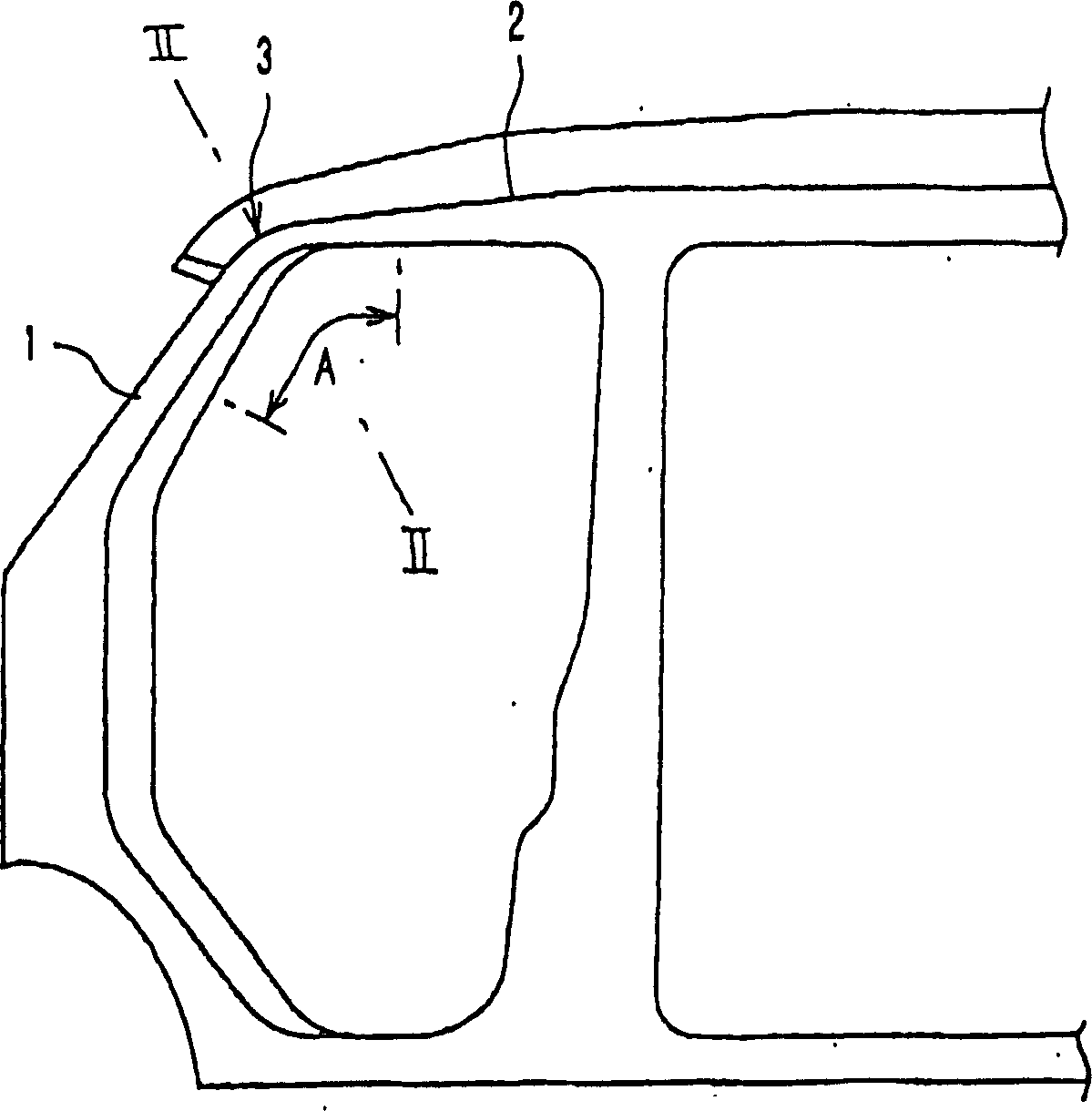

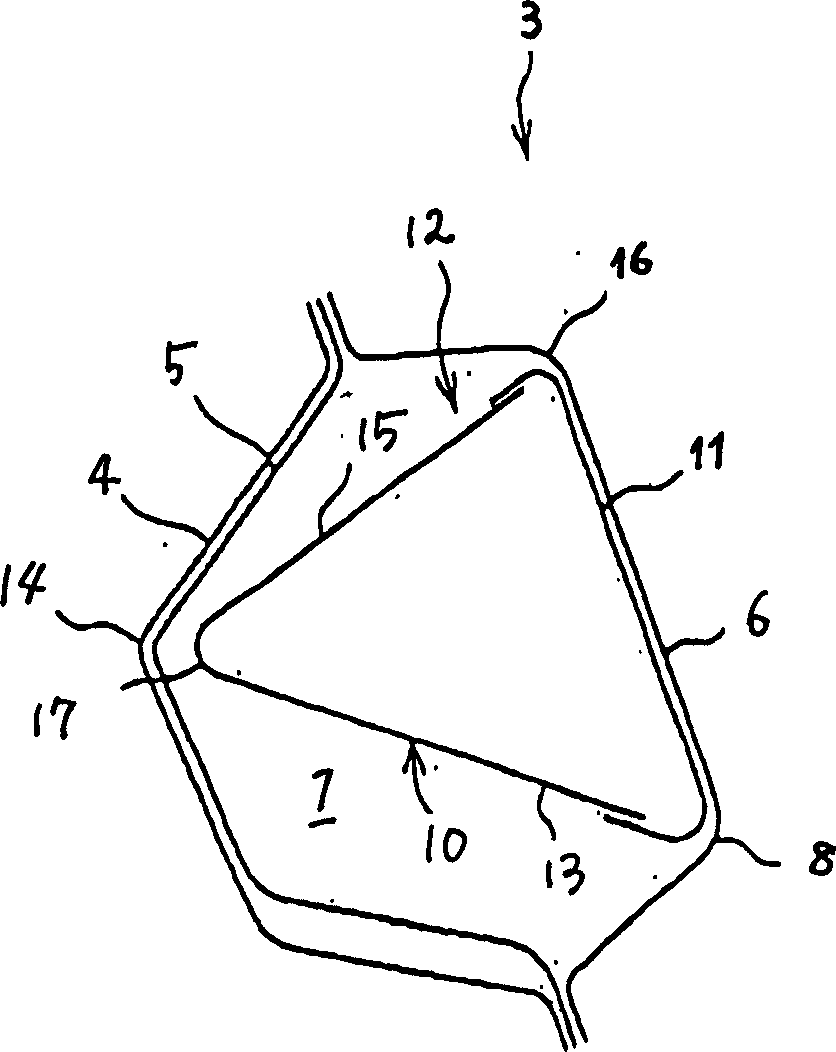

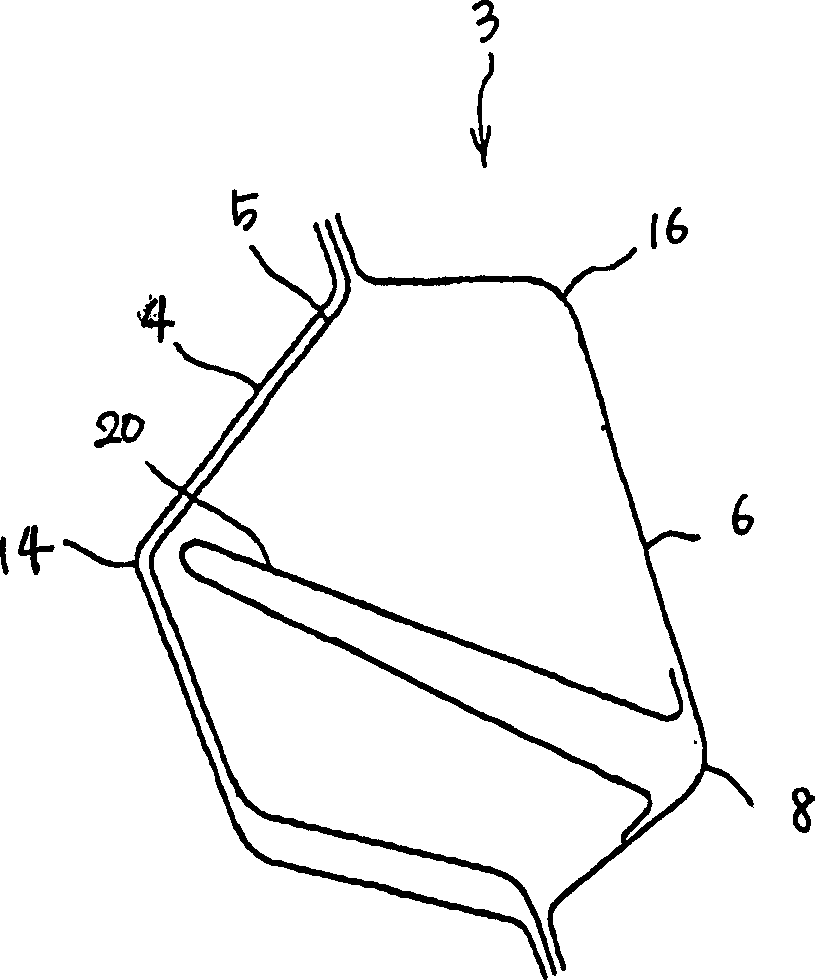

[0016] exist figure 1 and figure 2 In the shown first embodiment, the corner portion 3 where the front support beam 1 of the vehicle body is connected to the roof side rail 2 has a cross-section that is inclined with respect to the up, down, front and rear directions, and has an outer panel 4 and a slanting frame 5 that are superimposed on each other, and an inner panel 6 jointed, substantially polygonal hollow section 7 . In the range of part A extending from the front support beam 1 to the upper side beam 2 through the corner portion 3, the reinforcing member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com