Cam shaft angle sensor mounting structure of IC engine

An angle sensor and installation structure technology, applied in the direction of machines/engines, instruments, valve devices, etc., can solve the problems of lengthening the distance between front and rear wheels and increasing the size of motorized two-wheeled vehicles, so as to avoid the increase in size, realize simplification, Realize the effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

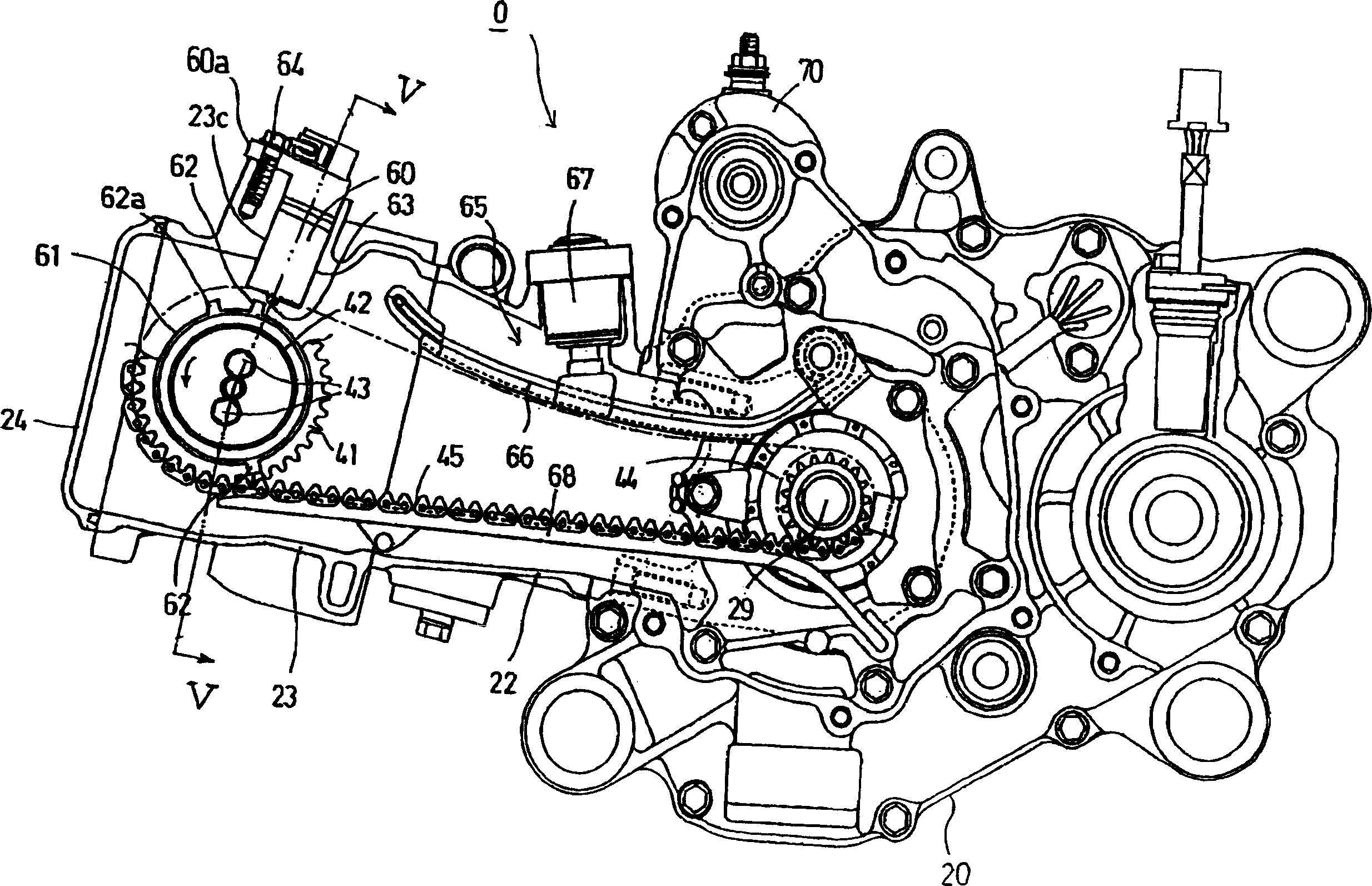

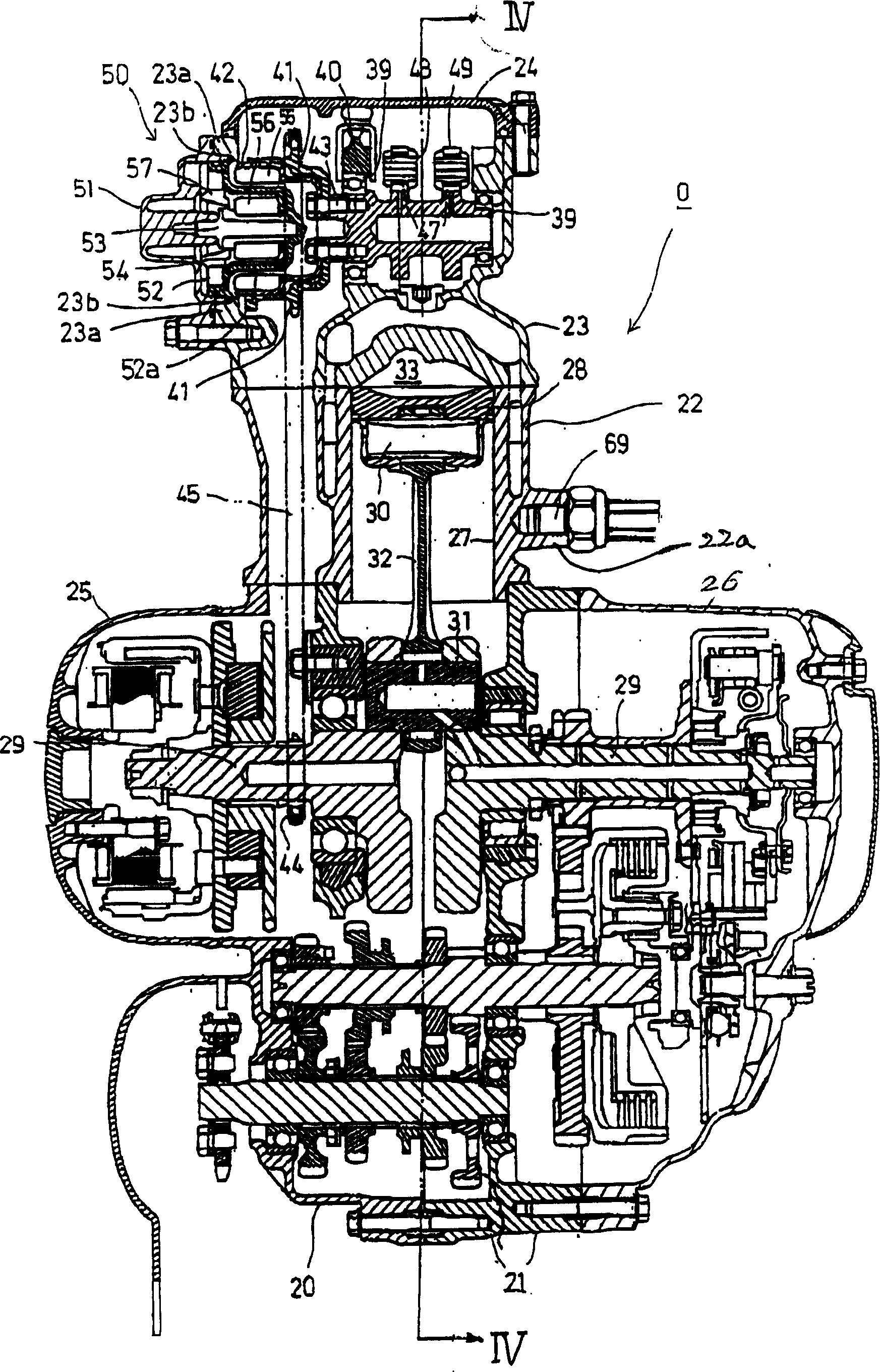

[0019] Below, explain Figure 1 to Figure 5 An embodiment of the invention is shown.

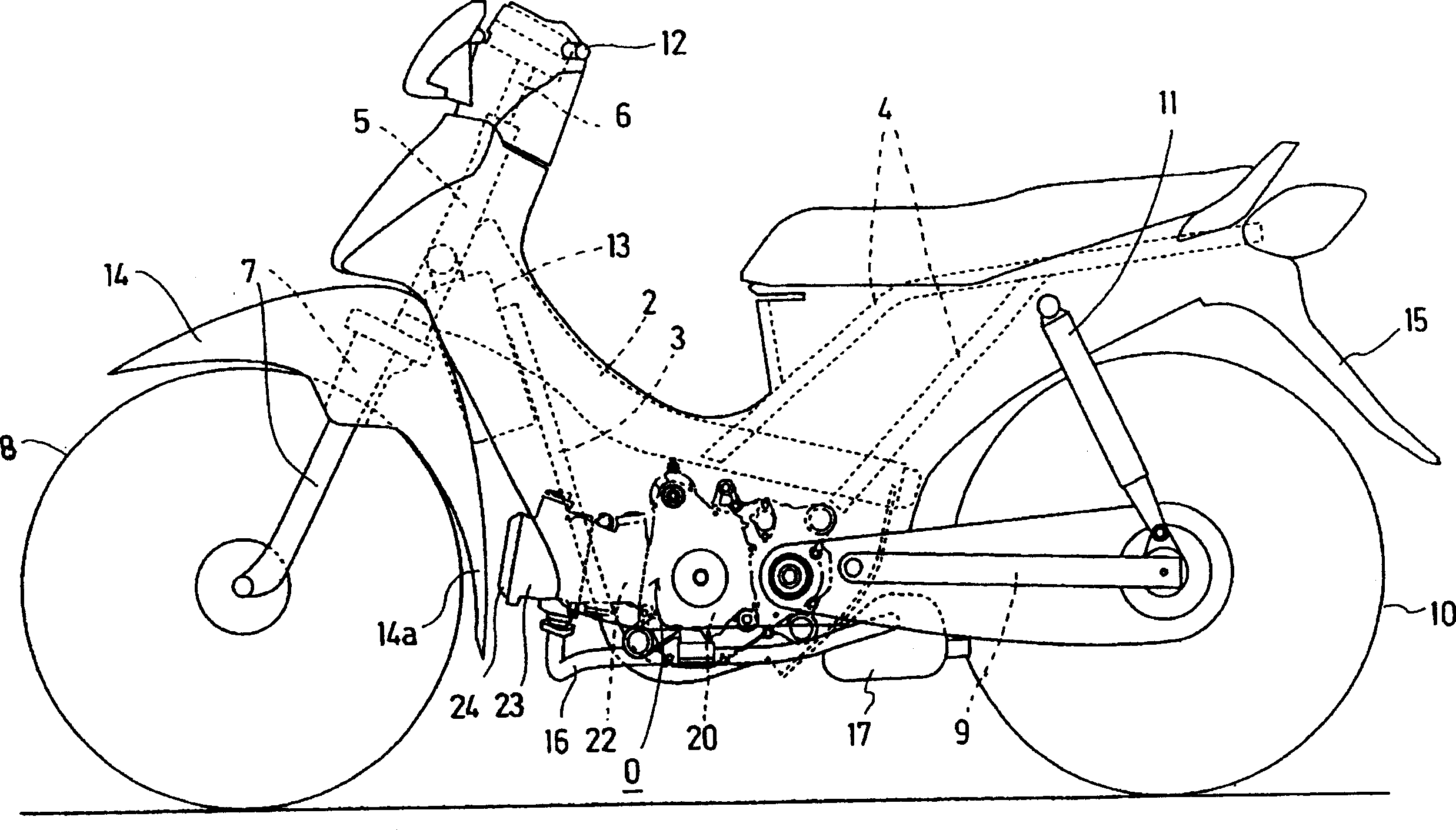

[0020] Such as figure 1 As shown, the overhead valve type four-stroke cycle internal combustion engine 0 related to the present invention is installed on a relatively small (not small) motorized two-wheeled vehicle 1; the body of the motorized two-wheeled vehicle 1 is made up of the following parts: The main frame 2 is inclined from the front upper part of the motor vehicle 1 to the rear lower part; the downpipe 3 is integrated with the front upper part of the main frame 2; Combined into one, pointing from the rear lower part of the main frame 2 to the obliquely rear upper part; the front main pipe 5 is integrated with the front end of the main frame 2. The above-mentioned downcomer 3 is inclined from the front upper part to the oblique rear and downward, and then extended to the rear, and its rear end is integrated with the rear lower part of the above-mentioned main frame 2; The cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com