Production method and preparation method of glucans

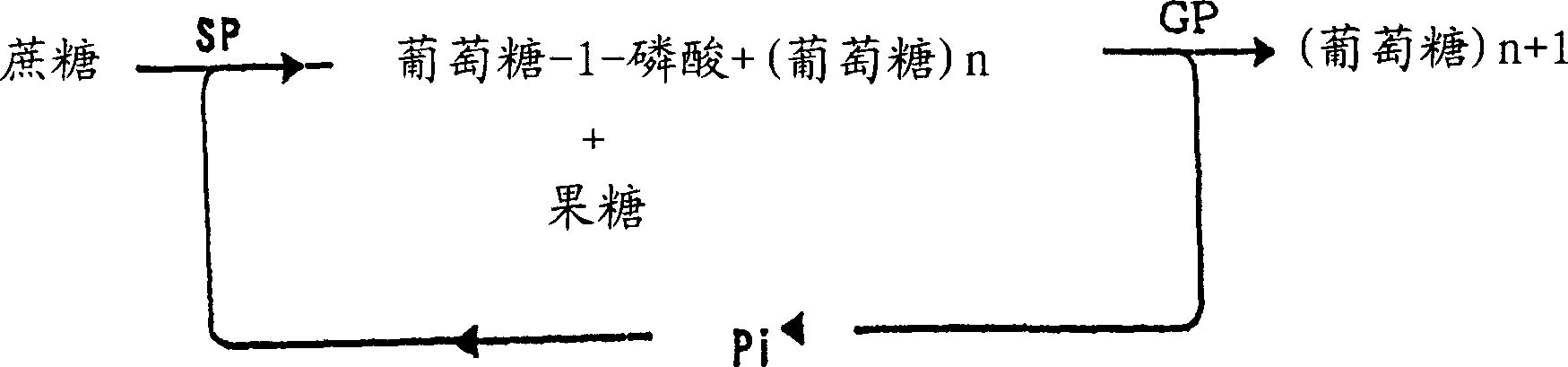

A technology for glucan and glucose, applied in the field of production of glucan and its derivatives, can solve the problems of undisclosed thermal stability of sucrose phosphorylase, cost and human safety, environmental problems are not good, prediction and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

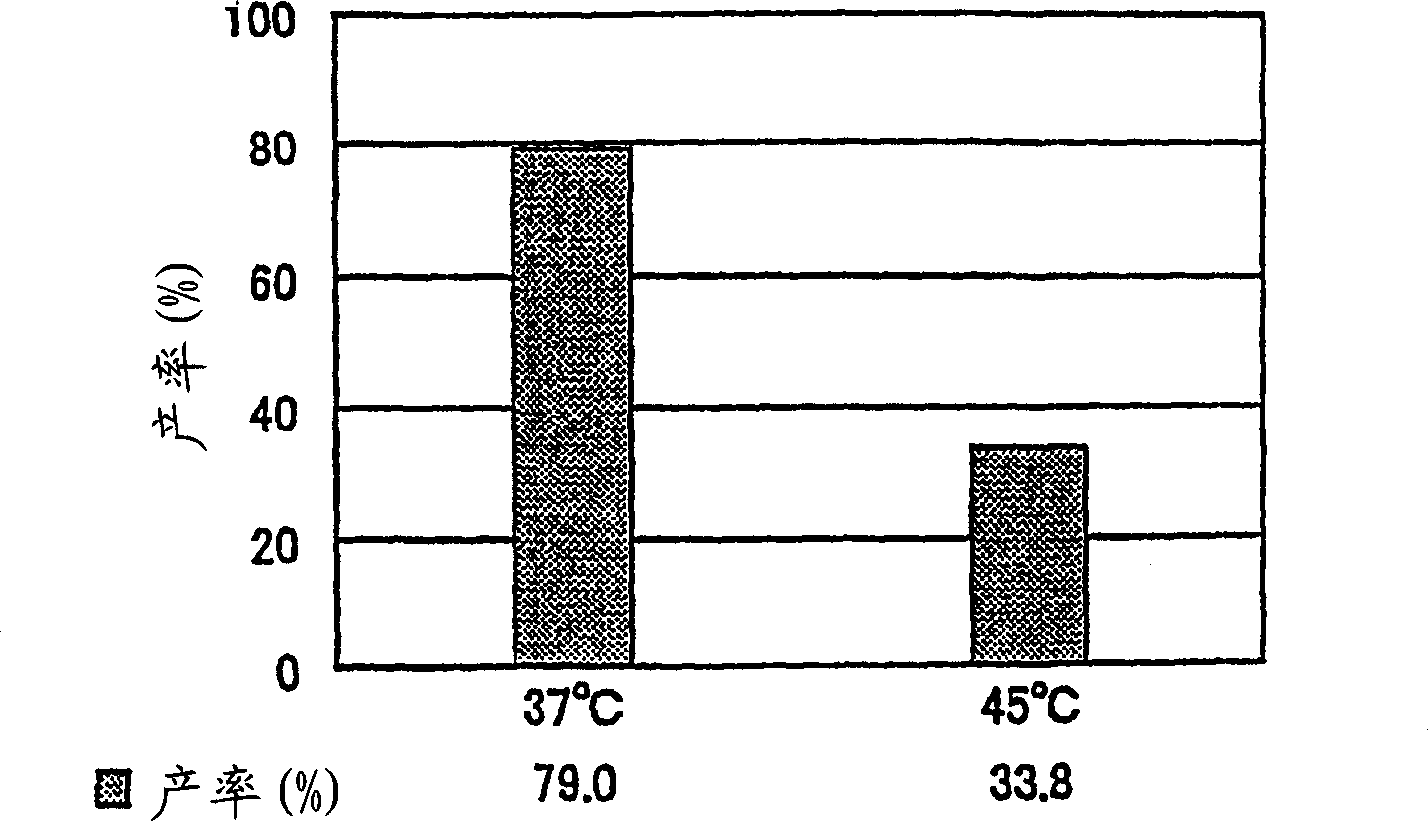

Embodiment 2-1 to 2-5 and comparative Embodiment 2-1 to 2-7

[0368] (Examples 2-1 to 2-5 and Comparative Examples 2-1 to 2-7: Amylose is synthesized using a small amount of enzyme)

[0369] Synthesis of amylose was carried out using a reaction mixture whose composition (at the start of the reaction) is shown in Table 3 below.

[0370] Numbering

sucrose

(%)

G7

(mM)

Pi

(mM)

SP(U / g

sucrose)

GP(U / g

sucrose)

reaction

temperature

Comparative Example 2-1

4

2

20

5

5

37℃

Comparative Example 2-2

8

4

40

5

5

37℃

Comparative Examples 2-3

10

5

50

5

5

37℃

Comparative Examples 2-4

15

7.5

75

5

5

37℃

Comparative Examples 2-5

20

10

100

5

5

37℃

Comparative Examples 2-6

25

12.5

125

5

5

37℃

Comparative Examples 2-7

4

2

20

5

5

45℃

Example 2-1 ...

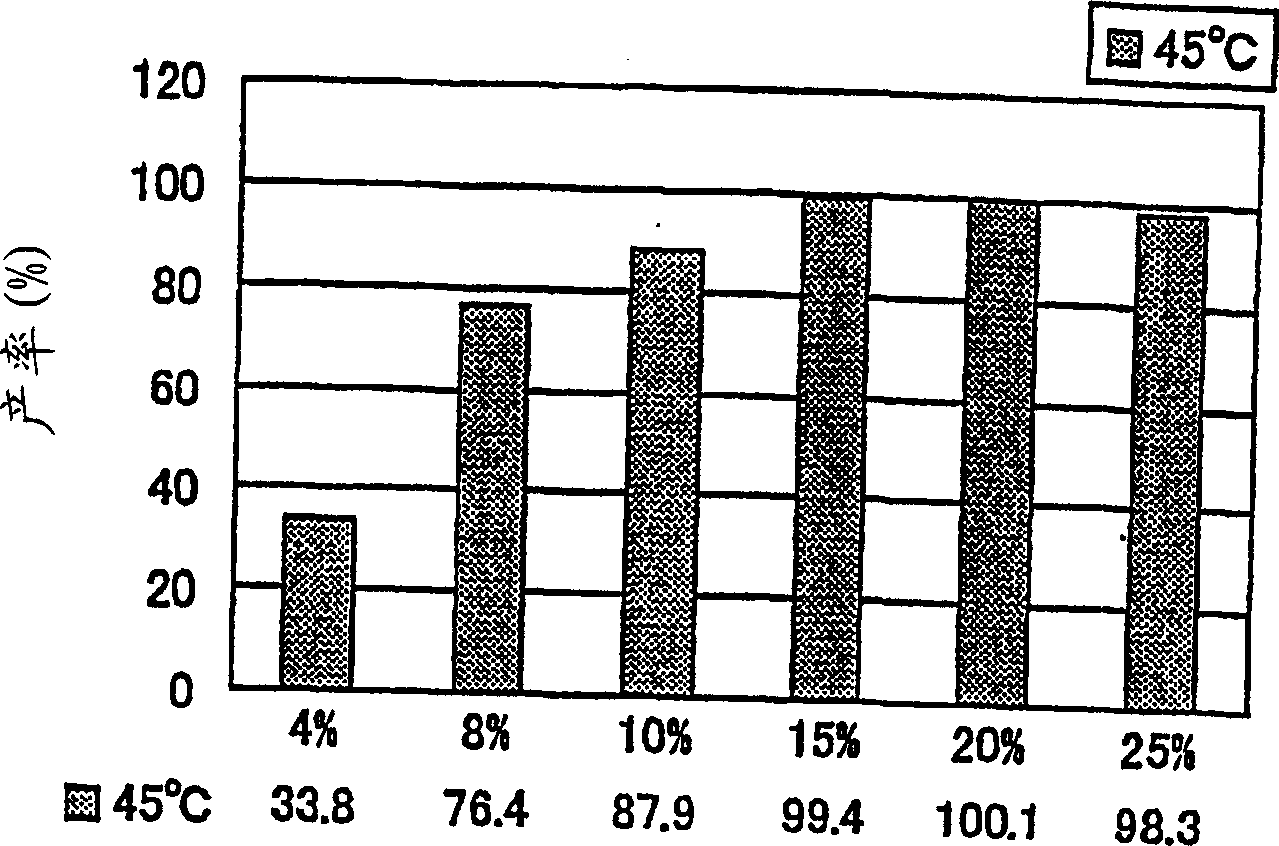

Embodiment 3-1-1 to 3-2-5 and comparative Embodiment 3-1-1 and 3-2-1

[0379] (Examples 3-1-1 to 3-2-5 and Comparative Examples 3-1-1 and 3-2-1: Synthesis of Amylose Using Thermostable Sucrose Phosphorylase)

[0380] Synthesis of amylose was carried out using a reaction mixture whose composition (at the beginning of the reaction) is shown in Table 4 below.

[0381] Numbering

sucrose

(%)

G7

(mM)

Pi

(mM)

SP(U / g

sucrose)

GP(U / g

sucrose)

reaction

temperature

comparative example

3-1-1

4

2

20

10

10

45℃

Example 3-1-1

8

4

40

10

10

45℃

Example 3-1-2

10

5

50

10

10

45℃

Example 3-1-3

15

7.5

75

10

10

45℃

Example 3-1-4

20

10

100

10

10

45℃

Example 3-1-5

25

12.5

125

10

10

45℃

comparative example

3-2-1

4

2

20

10

10

...

Embodiment 4-1-1 to 4-2-5, and comparative Embodiment 4-1-1 and 4-2-1

[0392] (Example 4-1-1 to 4-2-5, and comparative example 4-1-1 and 4-2-1: adopt a small amount of enzyme and thermostable sucrose phosphorylase to synthesize amylose)

[0393] Synthesis of amylose was carried out using a reaction mixture whose composition (at the start of the reaction) is shown in Table 5 below.

[0394] Numbering

sucrose

(%)

G7

(mM)

Pi

(mM)

SP(U / g

sucrose)

GP(U / g

sucrose)

reaction

temperature

comparative example

4-1-1

4

2

20

5

5

45℃

Example 4-1-1

8

4

40

5

5

45℃

Example 4-1-2

10

5

50

5

5

45℃

Example 4-1-3

15

7.5

75

5

5

45℃

Example 4-1-4

20

10

100

5

5

45℃

Embodiment 4-1-5

25

12.5

125

5

5

45℃

comparative example

4-2-1

4

2

20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com