Hydrolysis-resistance polyester composition and preparation method there

A composition and hydrolysis-resistant technology, which is applied in the field of hydrolysis-resistant polyester composition and its preparation, can solve the problems of difficulty in maintaining physical properties and insufficient practicability, and achieve the effect of improving hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

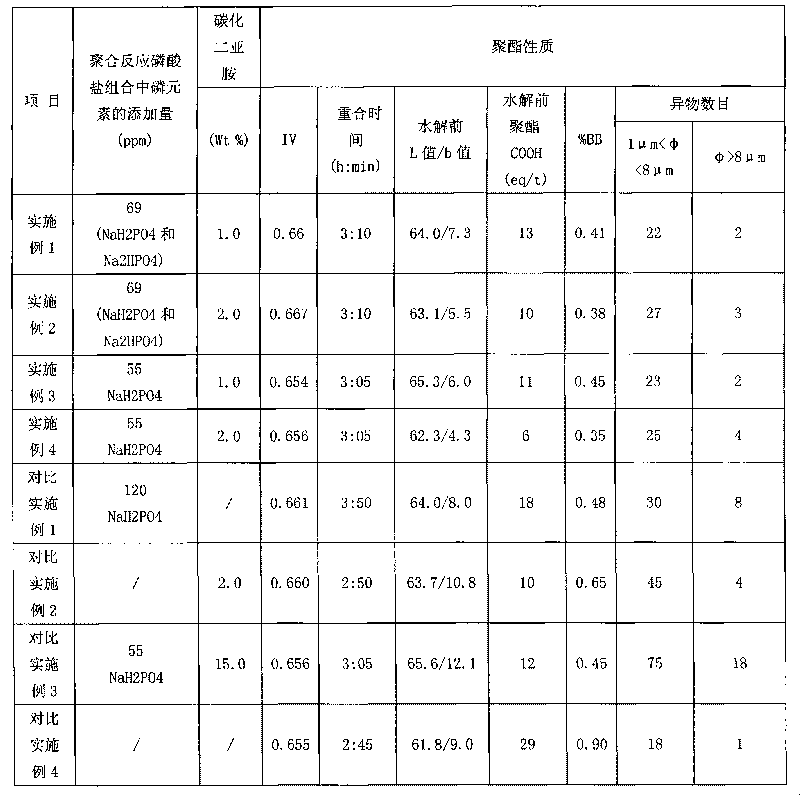

Examples

Embodiment 1

[0041] A hydrolysis-resistant polyester composition and its preparation method, which is obtained by precondensing aromatic dicarboxylic acid or its derivatives and aliphatic dihydric alcohol to obtain a small molecular polymer, and then performing polycondensation reaction on the small molecular polymer to obtain Polyester containing terminal carboxyl groups, antimony compound, phosphorus compound and magnesium compound are added in the polycondensation reaction to form a catalyst, and inorganic phosphate or composite inorganic phosphate is used as a buffer; The imine compound is blended and extruded to obtain a hydrolysis-resistant polyester composition. Relative to the weight of the polyester, the amount of phosphorus added in the inorganic phosphate is 1-100ppm, and relative to the weight of the polyester, 0.01-10wt% of an end-capping agent carbodiimide compound is added, preferably carbodiimide The added amount is 0.5-3.0 wt%.

[0042] The polyester is polyethylene terep...

Embodiment 2

[0056] Relative to the polyester weight, the following substances are added in amounts:

[0057] The addition amount of antimony element in the antimony compound is 120ppm;

[0058] The amount of phosphorus added in the phosphorus compound is 32ppm;

[0059] The addition amount of magnesium element in the magnesium compound is 60ppm;

[0060] The addition amount of potassium element in potassium hydroxide is 6ppm;

[0061] The amount of phosphorus added in sodium dihydrogen phosphate and disodium hydrogen phosphate is 69ppm;

[0062] N, N'-two-2,6-dicumylcarbodiimide addition 2.0wt%;

[0063] All the other are with embodiment 1. The viscosity of the obtained polyester is 0.667; the overlapping time is 3 hours and 10 minutes; the L value of the color of the polyester chip is 63.1, the b value is 5.5; the terminal carboxyl group content is 10eq / t; the obtained BB% after the hydrolysis treatment is 0.38. The results of observation of foreign objects were as follows: 27 forei...

Embodiment 3

[0065] Relative to the polyester weight, the following substances are added in amounts:

[0066] The addition amount of antimony element in the antimony compound is 120ppm;

[0067] The amount of phosphorus added in the phosphorus compound is 32ppm;

[0068] The addition amount of magnesium element in the magnesium compound is 60ppm;

[0069] The addition amount of potassium element in potassium hydroxide is 6ppm;

[0070] The amount of phosphorus added in sodium dihydrogen phosphate is 55ppm;

[0071] N, N'-two-2,6-dicumylcarbodiimide addition 1.0wt%;

[0072] All the other are with embodiment 1. The viscosity of the obtained polyester is 0.654; the overlapping time is 3 hours and 05 minutes; the L value of the color of the polyester chips is 65.3, the b value is 6.0; the terminal carboxyl group content is 11eq / t; the obtained BB% after the hydrolysis treatment is 0.45. The results of observation of foreign objects were as follows: 23 foreign objects with a size of 1-8 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com