Polyurethane-hard plastcs composite floor

A composite floor and hard plastic technology, applied in building materials, synthetic resin layered products, layered products, etc., can solve problems such as easy deformation, damage to the floor surface, damage to glass cups or hard objects, etc., to overcome Higher hardness, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

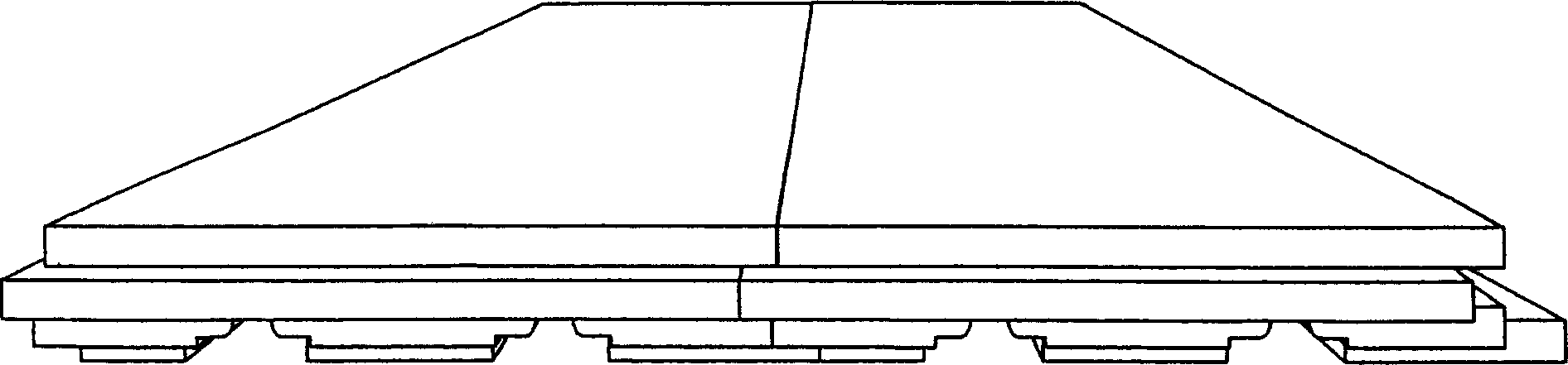

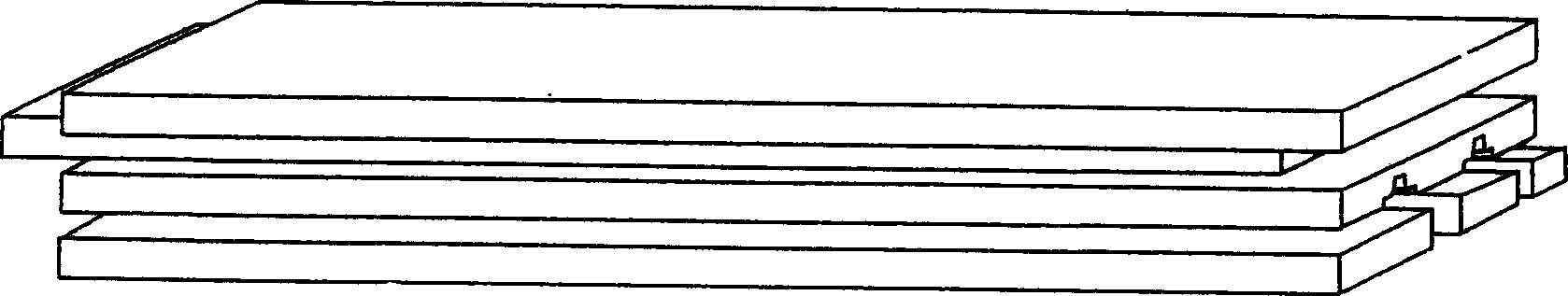

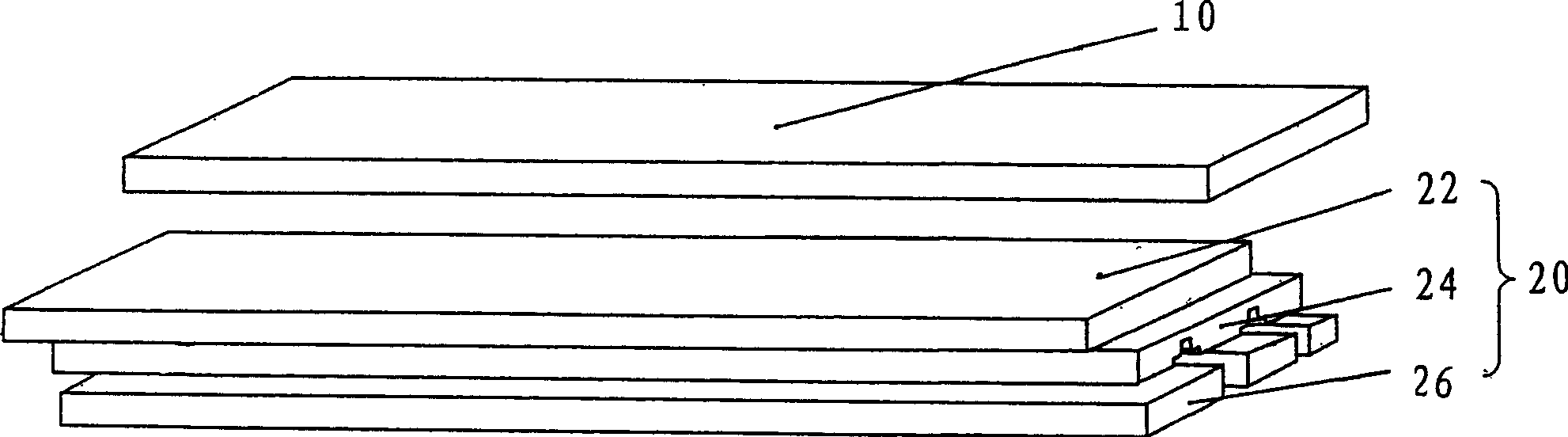

[0012] refer to figure 1 , figure 2 , image 3 and Figure 4 , The polyurethane-rigid plastic composite flooring of the present invention comprises a surface layer 10 and a bottom layer 20 bonded together. The bottom layer 20 includes an integrally formed upper layer 22, an intermediate layer 24 and a fixed bottom layer 26, and the upper layer 22, the middle layer 24, and the fixed bottom layer 26 are respectively formed with a protruding block (not marked in the figure) and a concave card groove (not marked in the figure). Mark), the protruding block is used to dock with the corresponding concave groove of another composite floor. The bottom of the middle layer 24 is provided with two parallel rows of stepped grooves 28 shrinking inward, and the fixed bottom plate 26 has two rows of channels 30 corresponding to the grooves 28 . The fixed bottom plate 26 is provided with screw holes, and the floor can be fixed on the ground by screws.

[0013] The material selected for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com