A sort of device and method for arranging multiple modling pipes produced by ceramics press

A cloth and equipment technology, applied in the field of cloth equipment, can solve the problems of complicated methods and equipment, inability to produce long and short ceramic tiles, etc., and achieve the effect of simple and reliable methods and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

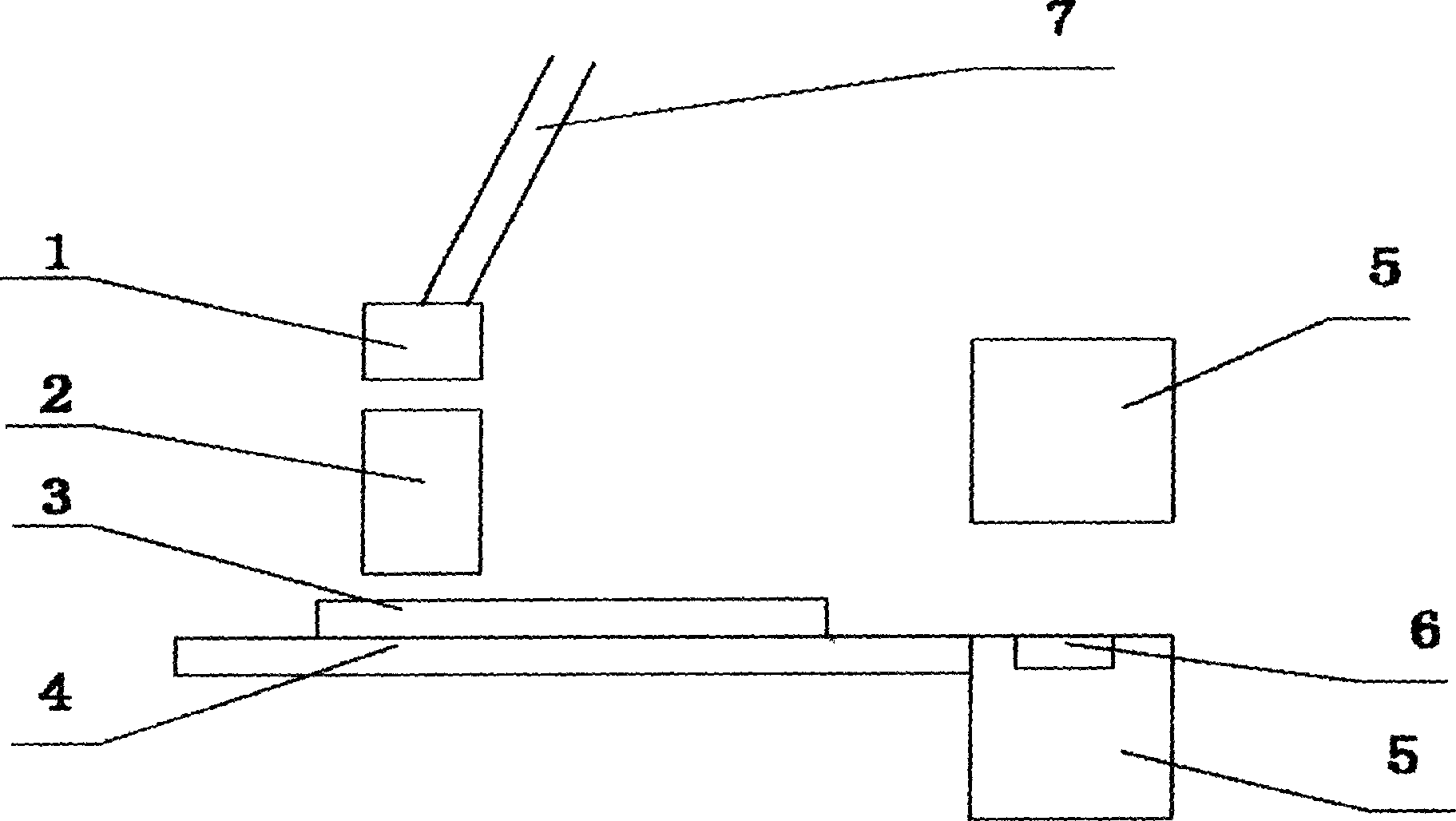

[0025] figure 1 Shown is an example of the distributing equipment of the present invention, and feeding pipe 7 puts various powder materials in the feeder 1, and feeder 1 moves back and forth along the left-right direction of press 5 above the distributing hopper 2, and feeds the cloth The bucket 2 feeds; the distribution bucket 2 or the grid 3 moves in the front and back direction of the press 5, and the distribution bucket 2 feeds the grid 3; the grid 3 on the bottom plate 4 moves to the press 5 to feed the mold frame 6. Feeder 1 is the feeder shown in Figure 8 and Figure 9, and the distribution hopper 2 is Figure 4 Cloth hopper shown.

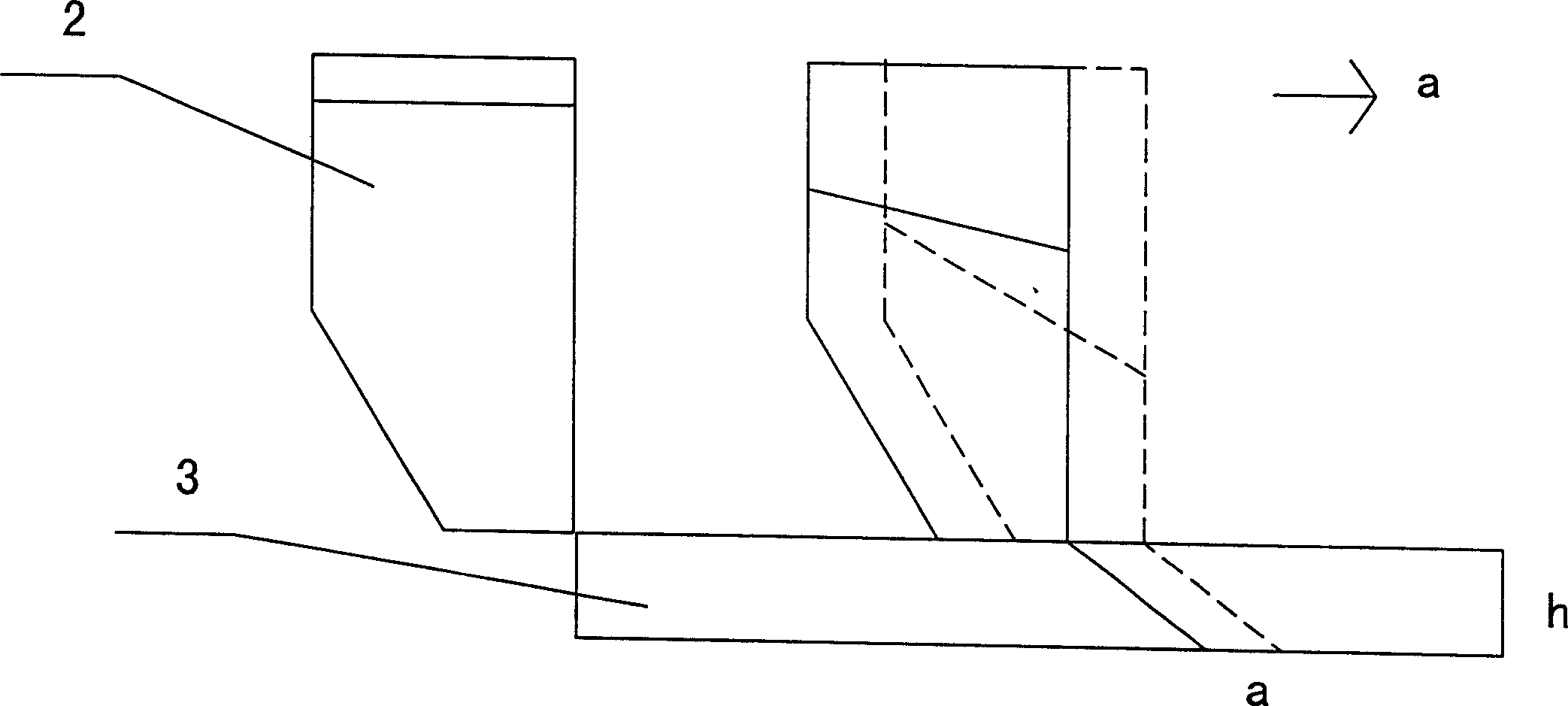

[0026] figure 2 Shown is an existing cloth hopper, such as image 3 As shown, when the existing distributing hopper is distributing, due to the good fluidity of the powder, when the distributing hopper...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap