Coater for dispersed slurry

A coating device and technology for dispersing pulp, which is applied to the device for coating liquid on the surface, the processing of textile materials, the process of adding pulp raw materials, etc., can solve the problem of poor fluidity of SAP dispersed pulp, difficulty in stable and uniform coating, Industrialized methods have not yet been developed and other problems, to achieve the effect of smooth surface, stable coating treatment, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

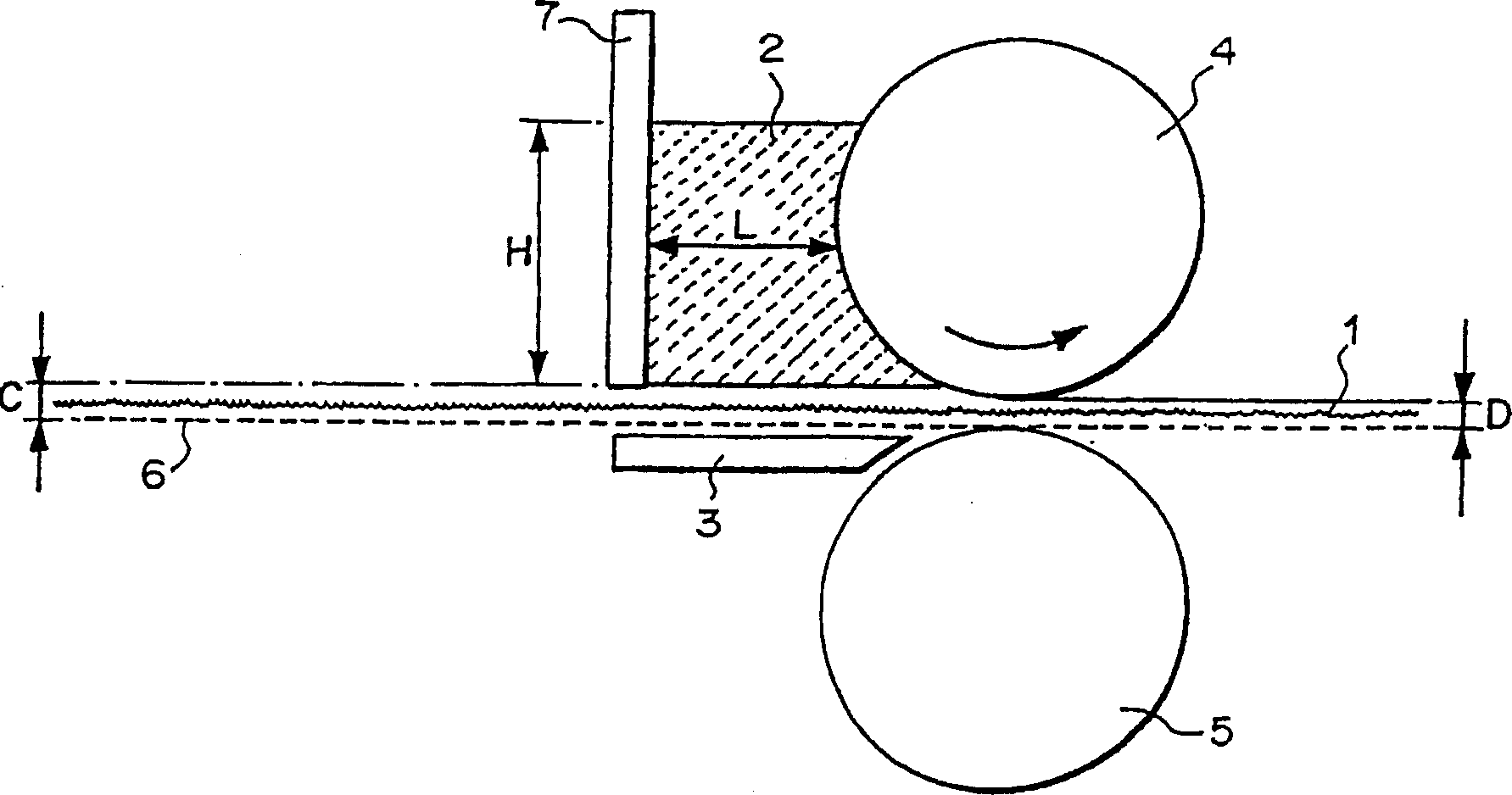

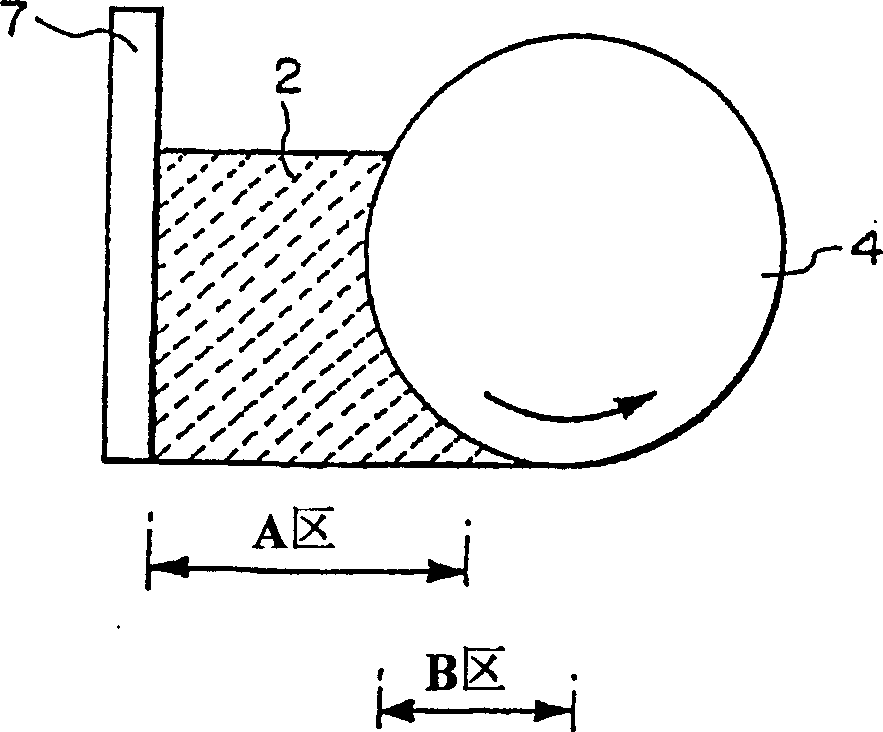

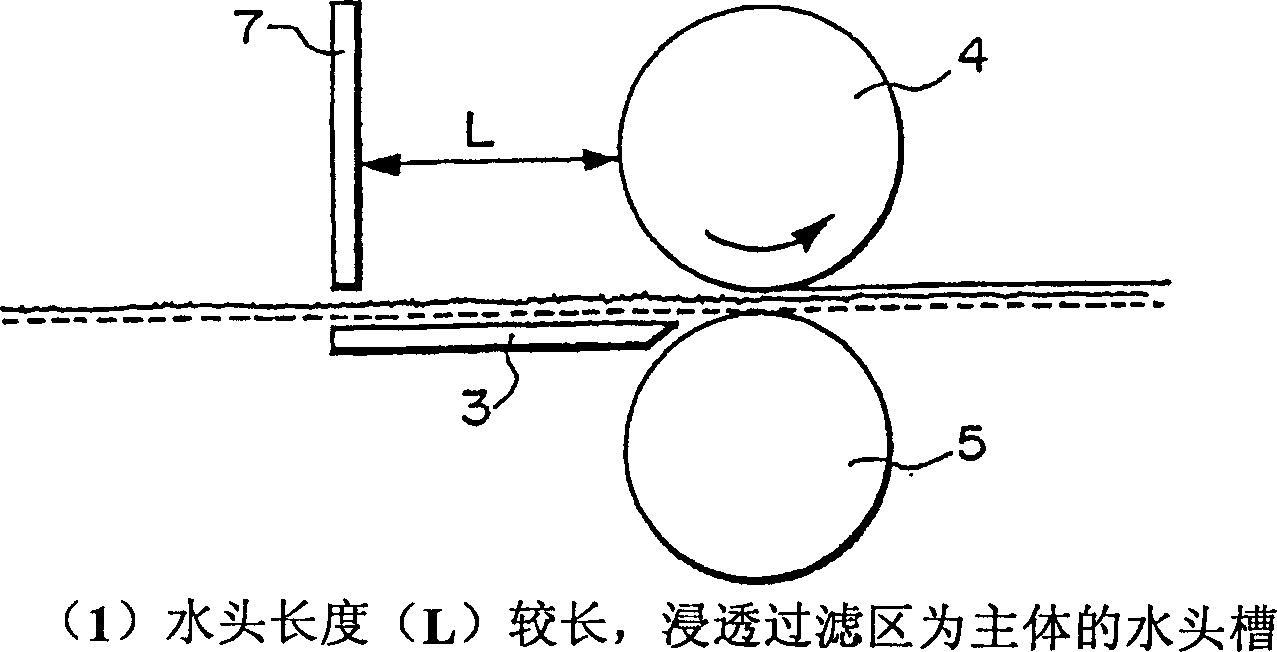

[0047] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0048] Prior to this, in order to understand the present invention, it is first necessary to understand the properties of SAP and SAP dispersion slurry, and the properties of non-woven fabric substrates.

[0049] The technology of coating high-viscosity and good fluidity slurry on a smooth film or metal foil is already a mature technology in the industry. This technology is roughly divided into mold coating, curtain coating and nozzle coating. There are two types of extrusion methods and coating head overflow methods with coating head slots. As the method of coating head, lip type direct coating head, intermittent direct coating head, intermittent reverse coating head, bottom area reverse roller coating head, direct gravure coating head, kiss coating Coating heads, extrusion coating heads, etc., and coating heads for various purposes ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com