Flat brushless motor

A brushless motor, flat technology, applied in the field of micro motors, can solve the problems of short life and high manufacturing cost, and achieve the effects of low manufacturing cost, high welding temperature and easy heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

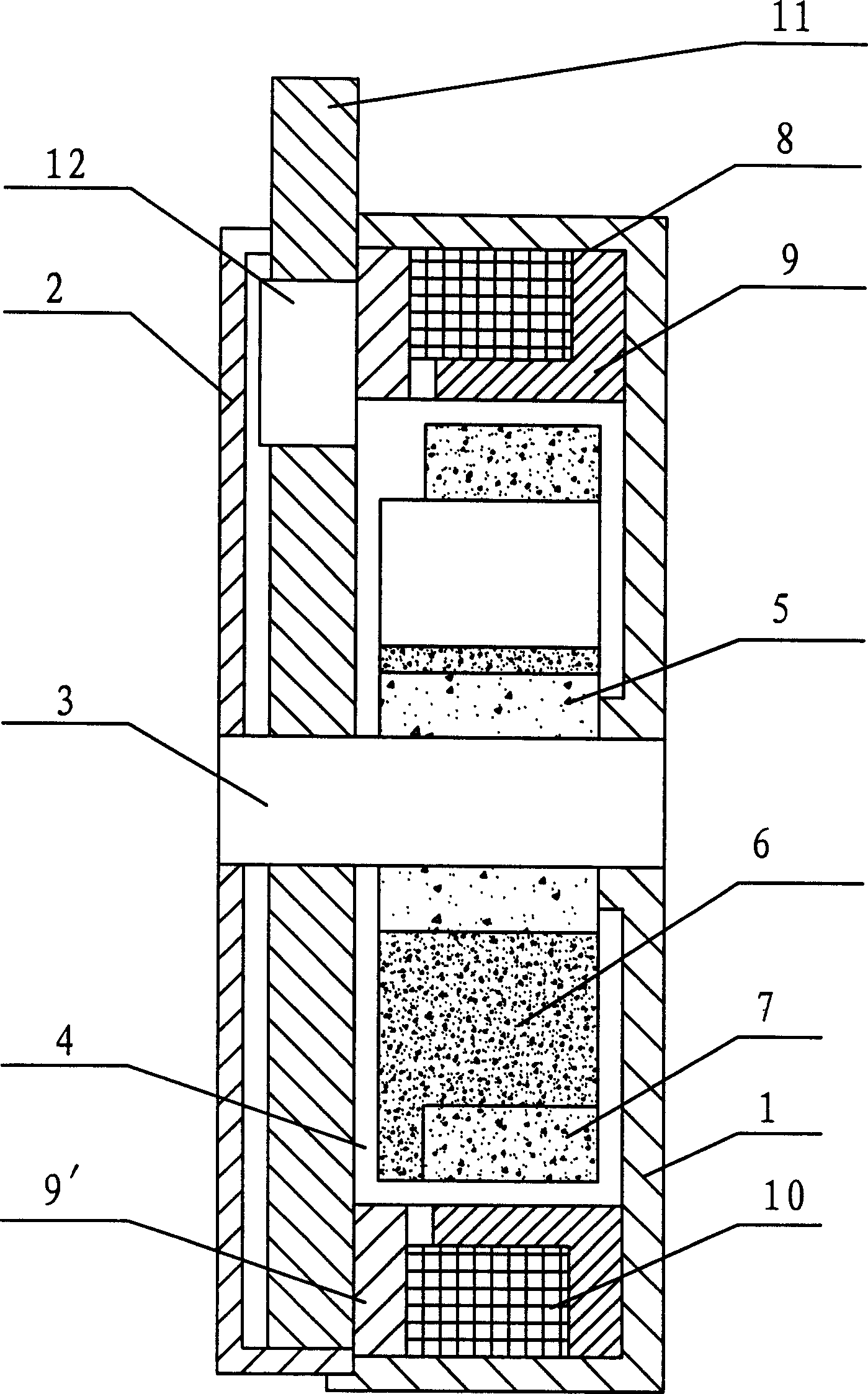

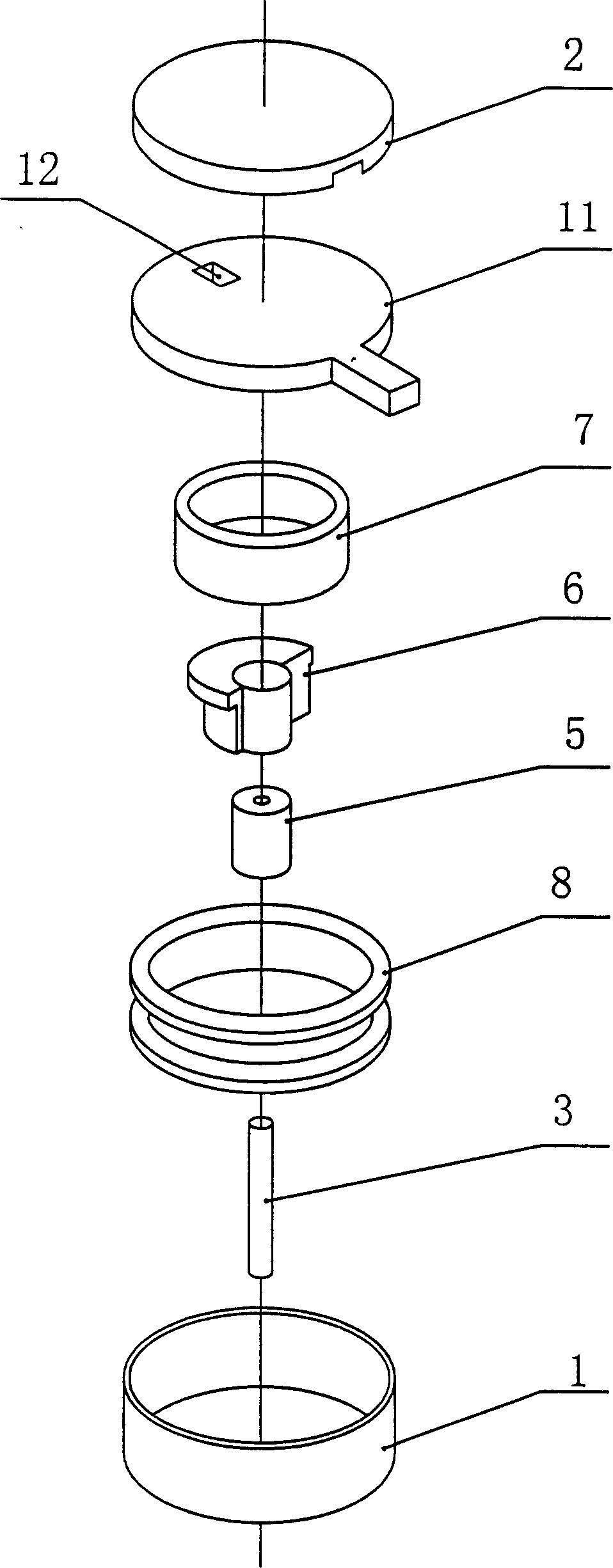

[0024] see figure 1 with figure 2 , The flat brushless motor of the present invention includes a cup-shaped base 1 , a cover 2 , a PCB printed circuit board 11 and an IC control integrated circuit 12 . A support shaft 3 is fixedly installed on the base 1 , a rotor assembly 4 is sleeved on the support shaft 3 , and a stator assembly 8 is arranged around the rotor assembly 4 . The PCB printed circuit board 11 is sleeved on the supporting shaft 3, located above the rotor assembly 4 and the stator assembly 8, placed in the cover 2, and supplies control current to the coils of the stator assembly. An IC control integrated circuit 12 composed of a sensor and a control integrated circuit is arranged on the PCB printed circuit board 11 . The sensor is placed at the position where the magnetic pole changes, and when the current flows through the coil, the magnetic pole will be generated, and they will act on the rotor assembly, causing the rotor to run and generate vibration.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com