Method for producing multiple leading-out terminal positive temperature coeffient PTC thermistor

A positive temperature coefficient, thermistor technology, applied in the direction of a resistor with a positive temperature coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

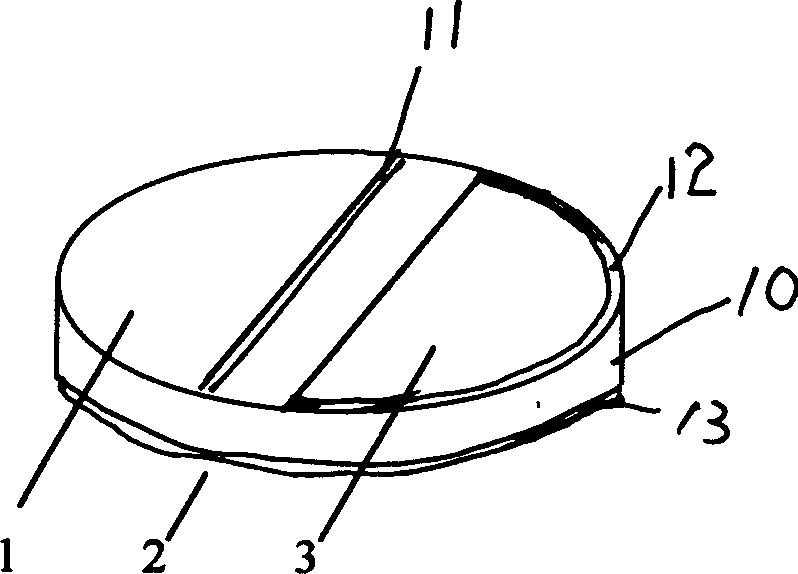

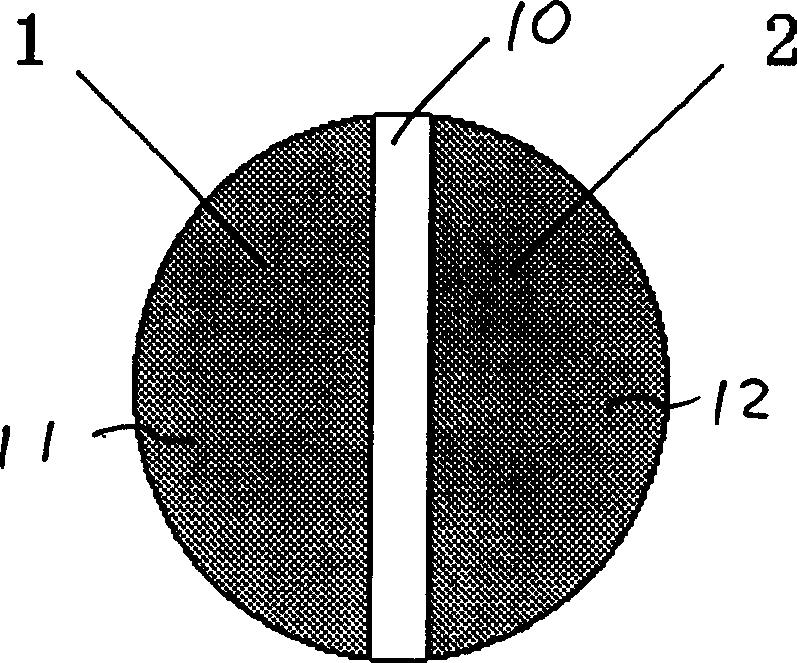

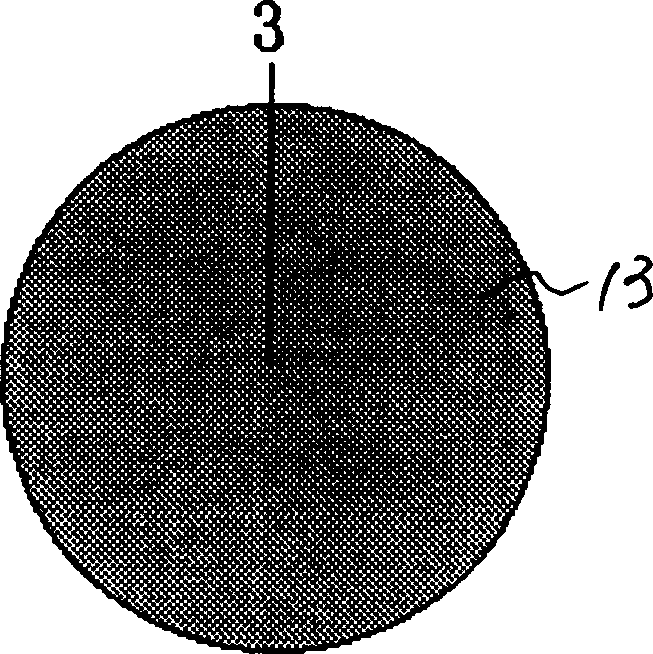

[0013] Such as figure 1 Schematic diagram of the structure of a three-electrode three-terminal PTC positive temperature coefficient thermistor, figure 2 The front schematic diagram of the three-electrode three-terminal PTC positive temperature coefficient thermistor and image 3 As shown in the schematic diagram of the back of the three-electrode three-terminal type PTC positive temperature coefficient thermistor, the front surface of the PTC thermistor tile 10 is coated with two areas of silver paste 11, 12, and the entire area of the back surface is coated with silver paste. Area 13. Two lead-out ends 1 and 2 drawn from the two silver paste areas on the front side, and one lead-out end 3 drawn out from the silver paste on the back side. The lead-out end can also be pins of other forms. After the production is completed, the whole is wrapped with a layer of insulating material, such as epoxy resin or silicone resin. in:

[0014] The resistance between terminals 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com