Placing type matting

A technology of tatami mats and core materials, applied in fastening devices, horse protection devices, mattresses, etc., can solve problems such as human injury, poor connection force, air pollution, etc., improve work efficiency, and save waiting time for drying , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

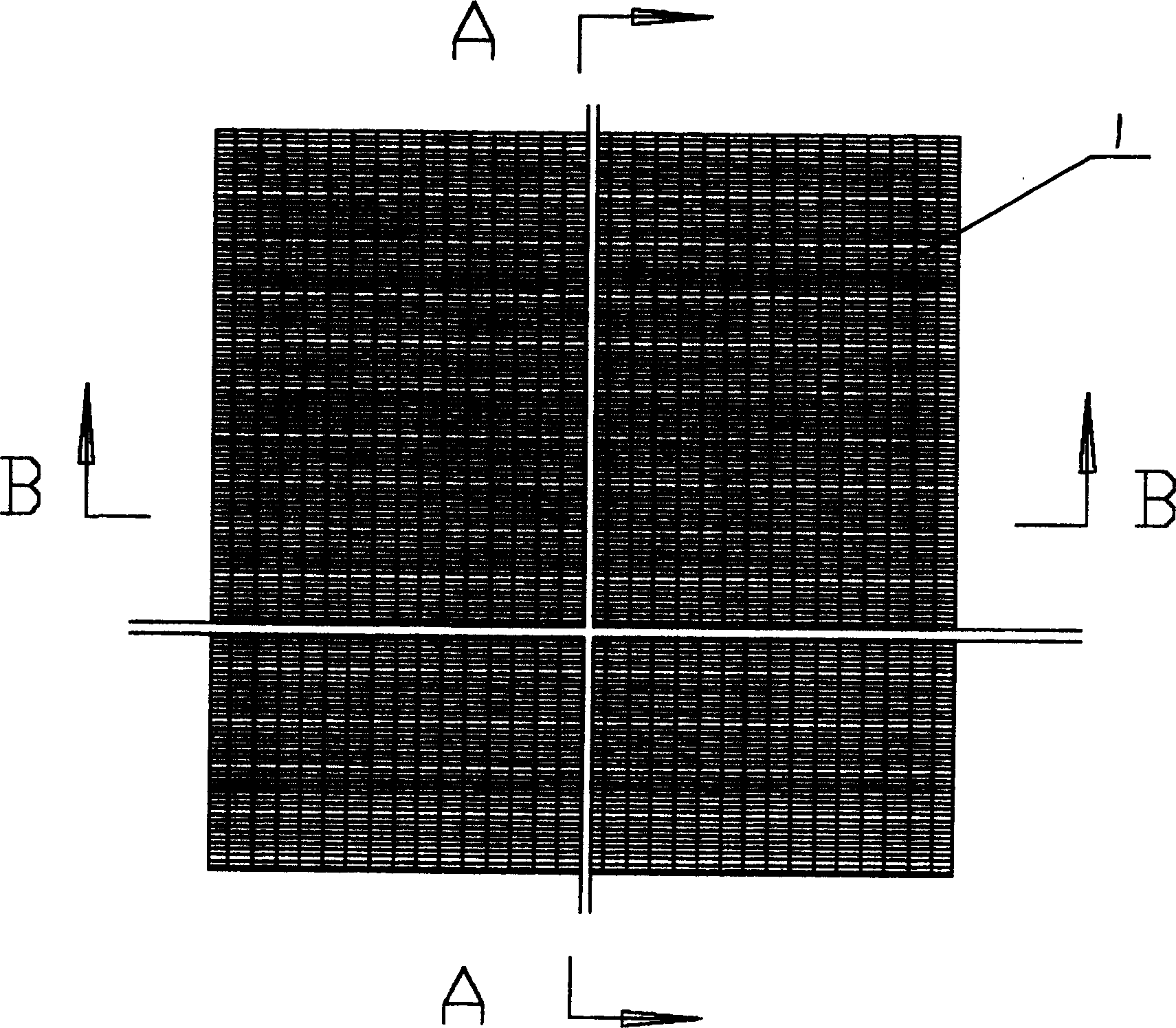

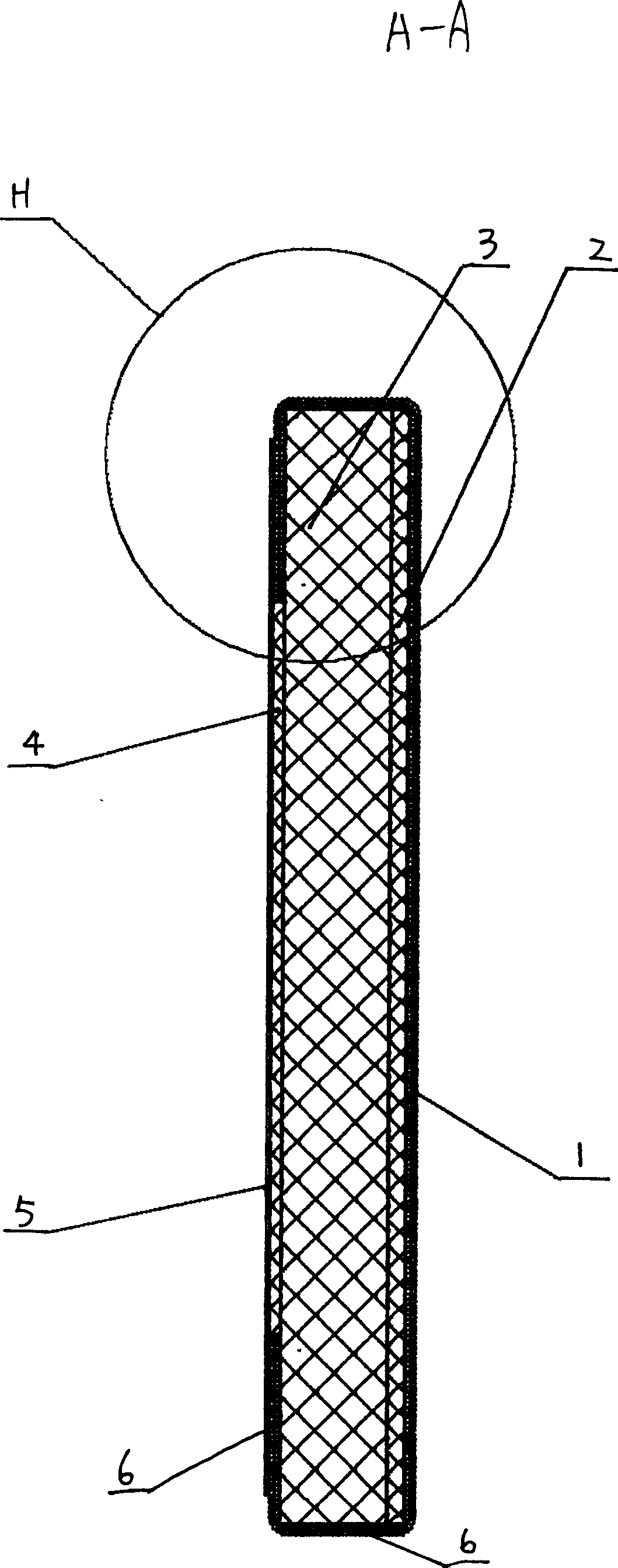

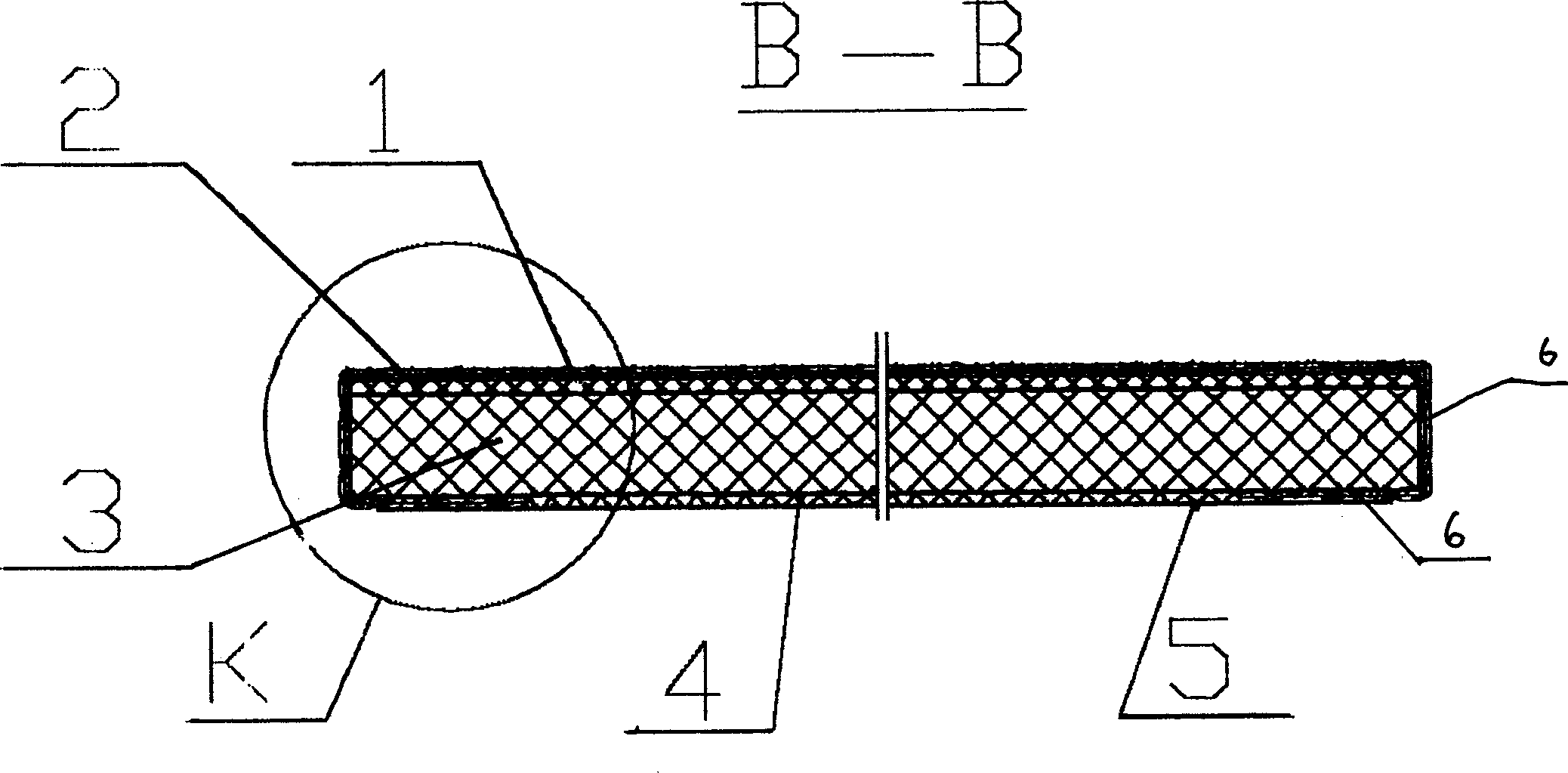

[0014] See attached figure 1 To attach Figure 5 , a placed tatami mat, comprising a core material 3, a stacked table 1 covering the upper surface of the core material 3, and a bottom lining 5 covering the lower surface of the core material 3; the stacked table 1 is on four sides of the core material 3 The edge part is bent downward and then inward to form a folded watch edge 6, which wraps the four side edges of the core material 3 and part of the lower surface of the core material 3, and the folded watch wrap 6 The inner surface is fixedly connected with the lower surface of the core material 3, and the fixed connection is bonded by hot-melt adhesive. The hot-melt adhesive is a solvent-free solid adhesive, which is formulated with thermoplastic polymer resin as the main body and various additives. They are solid at room temperature, and they can be melted by heating to obtain fluidity, infiltrate the surface of the adherend, and realize bonding by hardening after cooling. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com