Method for designing components of large piece of non-crystalline alloy

A technology of amorphous alloy and design method, which is applied in the field of design of amorphous alloy composition, and can solve problems such as incomplete compliance, amorphous alloy not fully conforming to empirical laws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Judgment of Alloy Amorphous Formation Ability

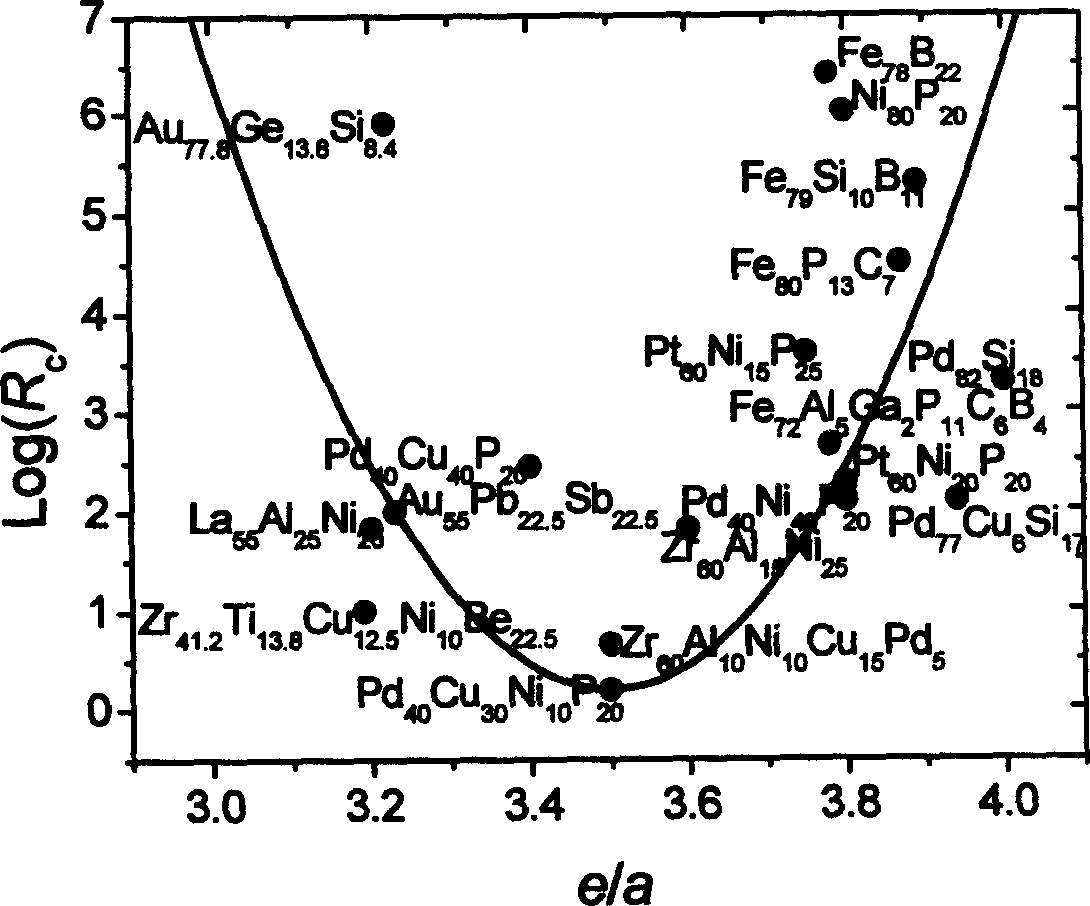

[0030] The critical cooling rate R of typical metallic amorphous alloys c For the relationship with the e / a value, seefigure 1 . The valence electron values of specific elements are listed in Table 1 [Zeitschrift fur Kristallographie 215 (2000) 429], and the e / a value of the alloy can be obtained by the algebraic sum of the corresponding elements. because the lowest R c The value corresponding to the best amorphous-forming ability is the way to measure liquids with the most negative enthalpy, so e / a = 3.5 at R c The minimum point of the curve indicates that the liquid is in the lowest energy state, the crystallization driving force is the smallest, and the amorphous formation ability of the alloy is the strongest here.

[0031] Table 1 Valence electron values of some elements

[0032] e e e e e

[0033] Be 2 Si 4 Ni 4 Zr 3.59 Pt 4

[0034] B 3 P 3 Cu 3 Nb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com