New type uniform diffuser for flow field

A technology of uniform diffusion and flow field, used in textile and papermaking, continuous winding spinning machines, open-end spinning machines, etc., can solve the problem of inability to flow continuously, uniformly, and stably, affecting product output and quality, and spatial location. Small and other problems, to achieve the effect of small occupied space, guaranteed production quality, and short flow length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

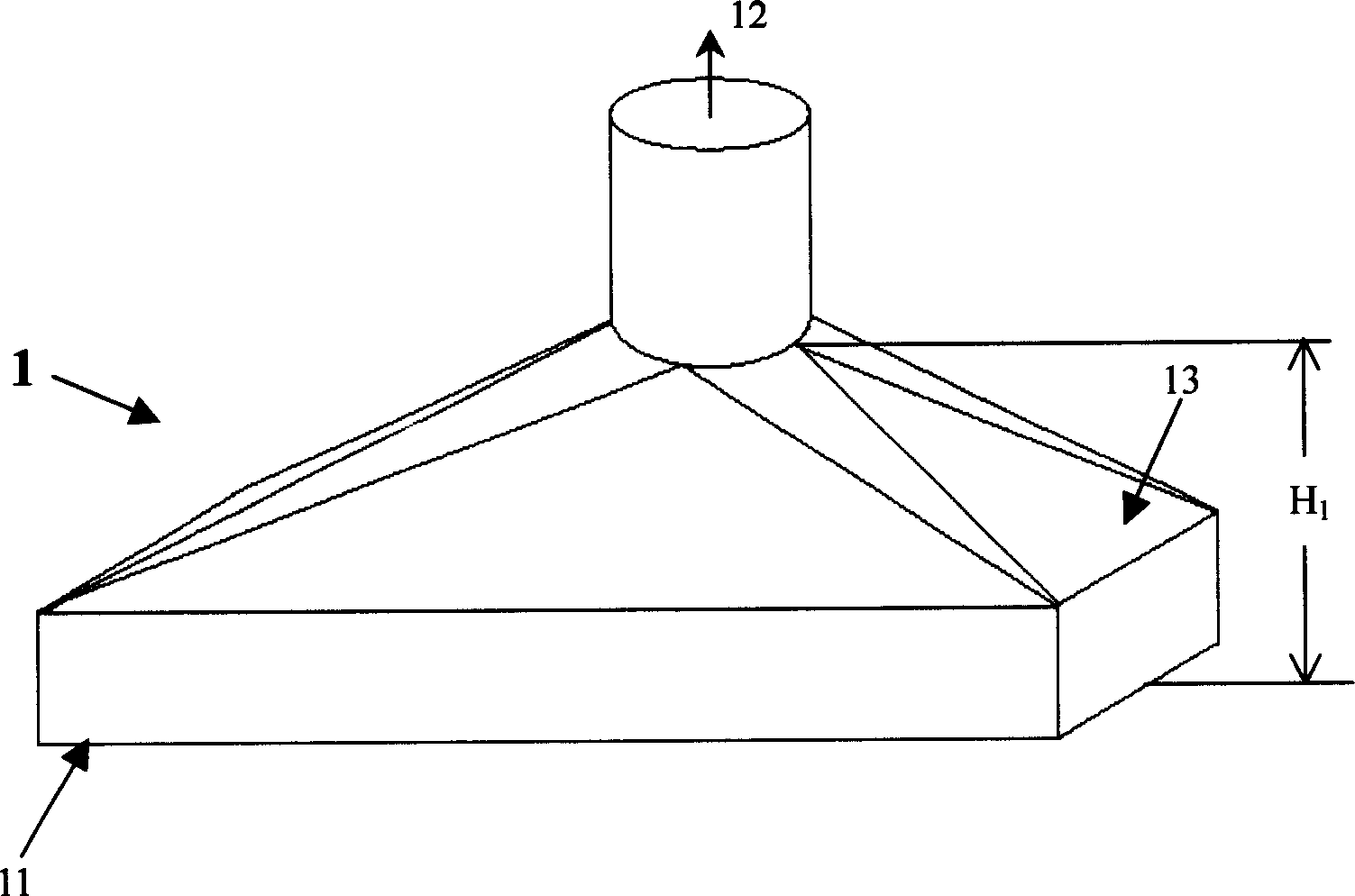

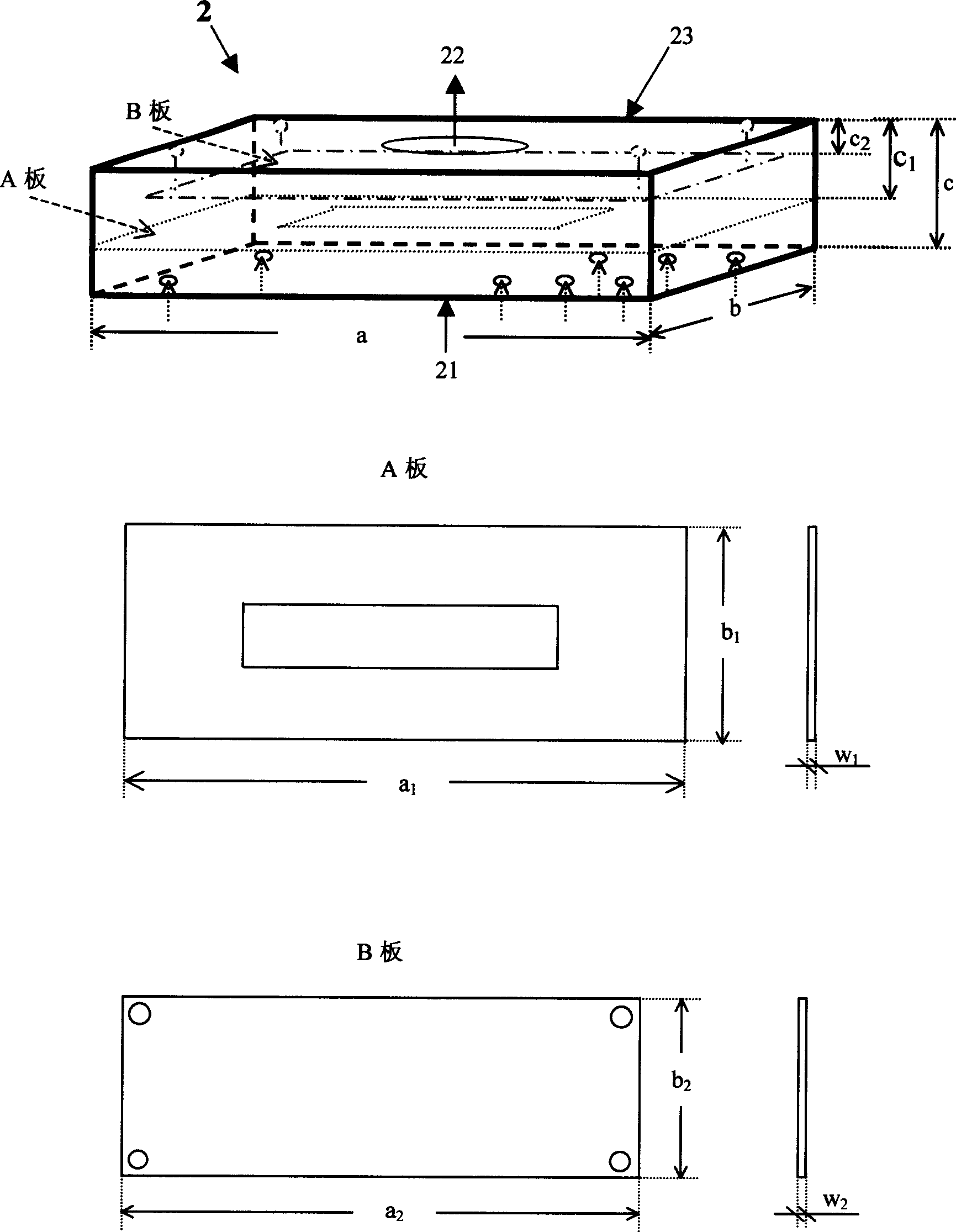

[0013] A new type of flow field uniform diffuser placed in the lower part of the gap between two rows of roving spindles or supporting spindles on the compact spinning or compact spinning equipment. 2.50 meters, the height c of the diffusion pipe 23 is 0.20 to 5.00 meters, and there are air inlets 21 and air outlets 22. The first equalizer A with rectangular holes is arranged in the diffusion pipe 23, and the first equalizer A with rectangular holes is arranged in the diffusion pipe 23. The length a of an equalizer plate A 1 0.30 to 25.50 meters, the width b of the first equalizer A with rectangular holes 1 0.10 to 2.50 meters, the thickness w of the first equalizer A with rectangular holes 1 0.50-1.50 mm, the height c of the first equalizer plate A with a rectangular hole from the upper surface of the diffuser pipe 23 1 It is 0.10 to 2.50 meters, and its periphery is connected with the inner wall of the diffuser tube 23; in the diffuser tube 23, there are also 4 steel wires...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com