Micro power consumption reciprocating apparatus

A reciprocating device, micro power consumption technology, applied in electromechanical devices, magnetic objects, electrical components, etc., can solve the problems of unstable operation, reduced service life, unreliable operation, etc., to achieve fast fluid response time, prolong service life, The effect of prolonging the electrical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The purpose of the present invention is achieved in the following ways:

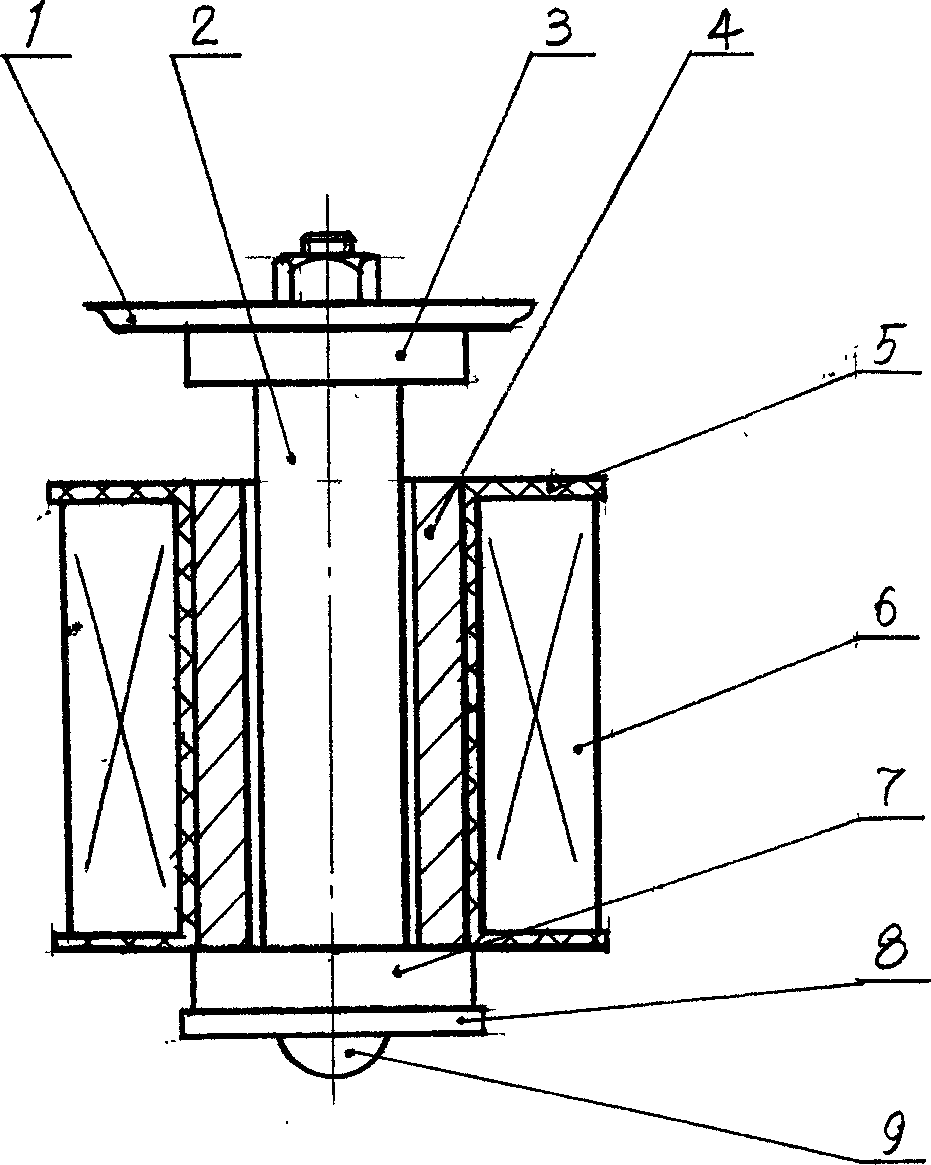

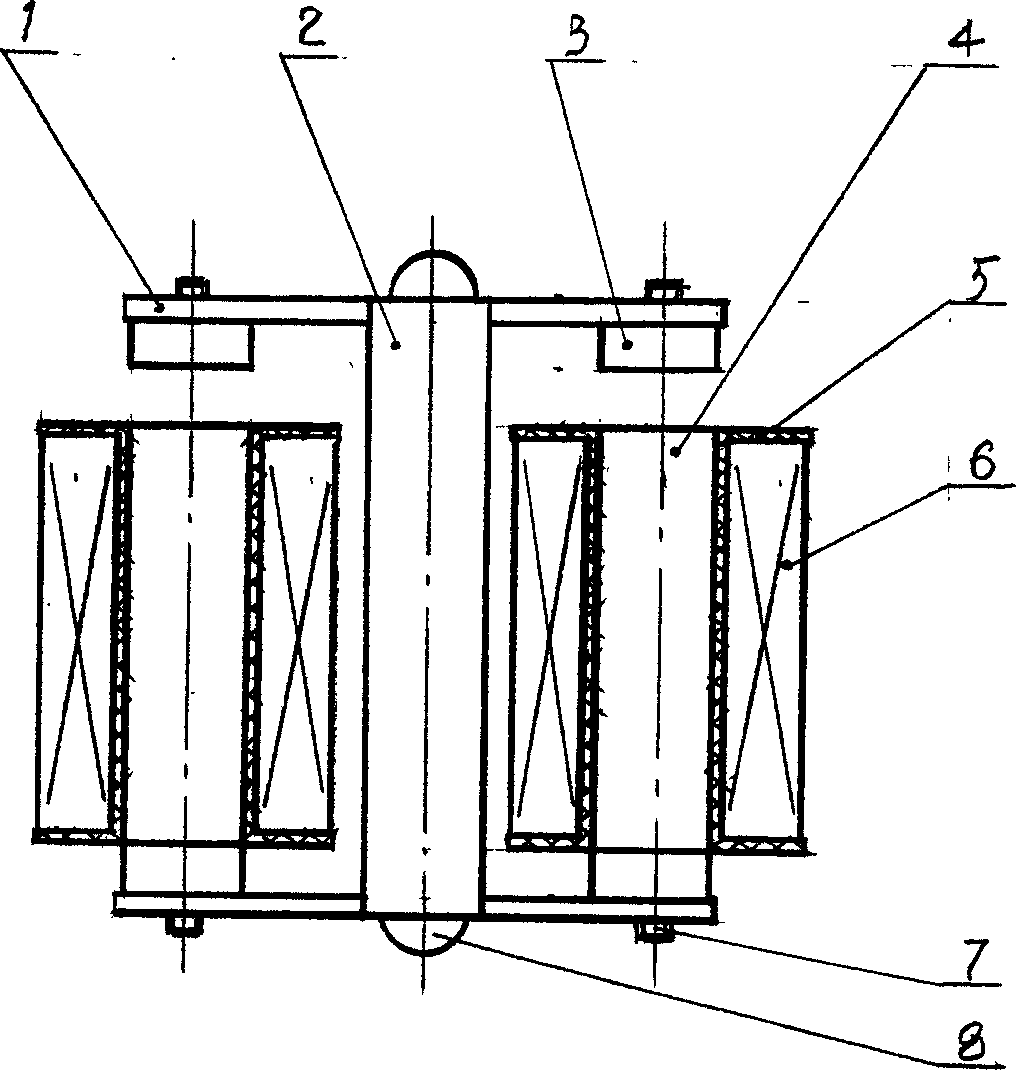

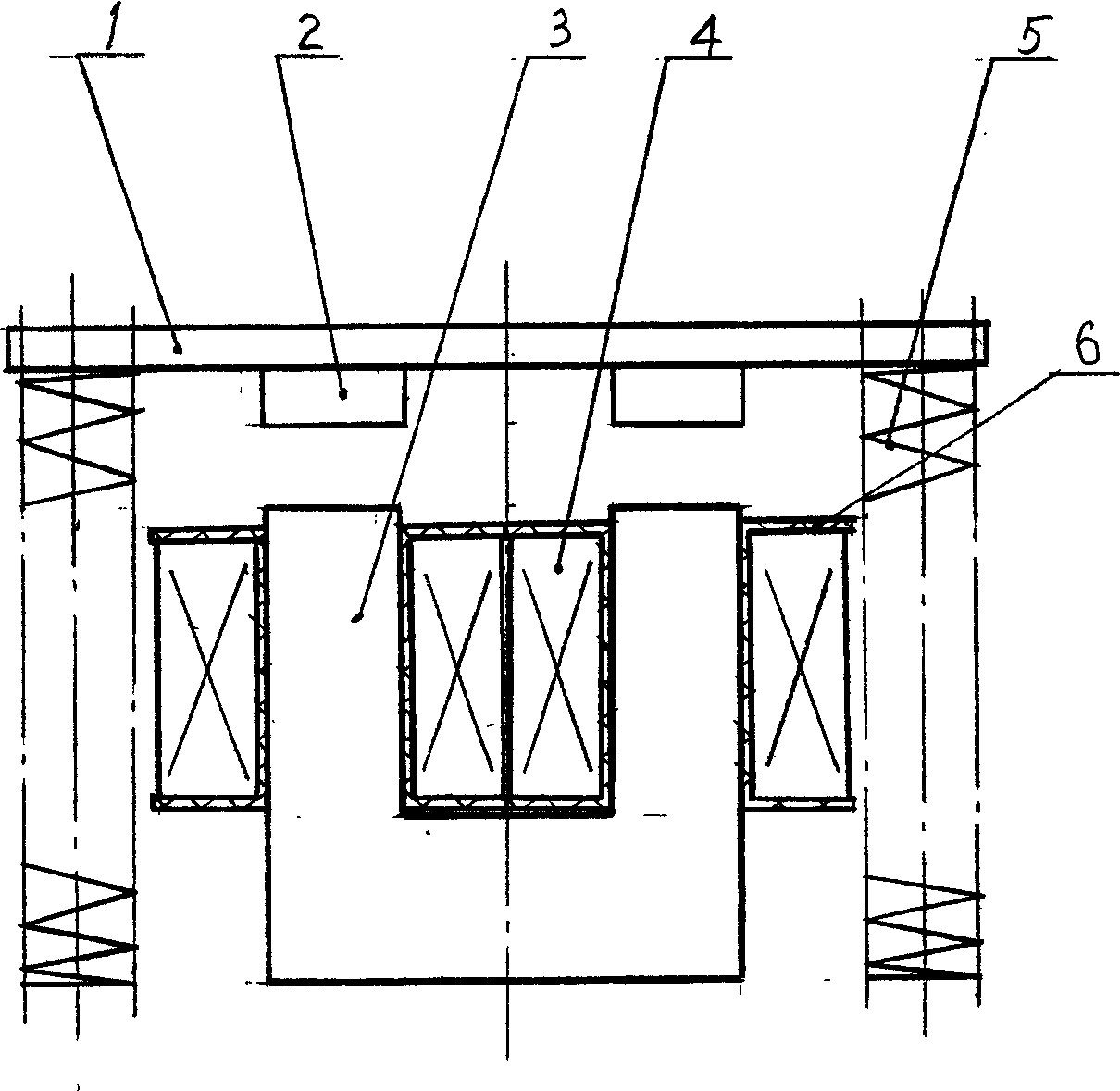

[0044] The device is equipped with a coil, wound on the coil bobbin. The coil bobbin is equipped with a ring-shaped soft iron core. The two ends of the ring-shaped soft iron core are installed along the central axis. The outer side of the coil bobbin is provided with permanent magnets with opposite polarities. The upper structure plate 6 and the pad iron 1 are fixed by bolts on the outer side of the permanent magnet; two sets of coils are wound on the coil frame, and the coil frame is equipped with soft iron cores, which are arranged on both sides of the bracket. The permanent magnets are arranged The two ends of the soft iron core have opposite polarities and are fixed on the end plate and bolted to the bracket to form an I-shaped motion frame; the permanent magnet is correspondingly installed on the end plate on the upper end of the U-shaped soft iron core. The coil The outside of the bobbin is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com