Yarn resistant twisting head

A technology for twist resistance and yarn, applied in the field of yarn resistance twist heads, can solve complex, expensive, constantly changing and other problems, and achieve the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

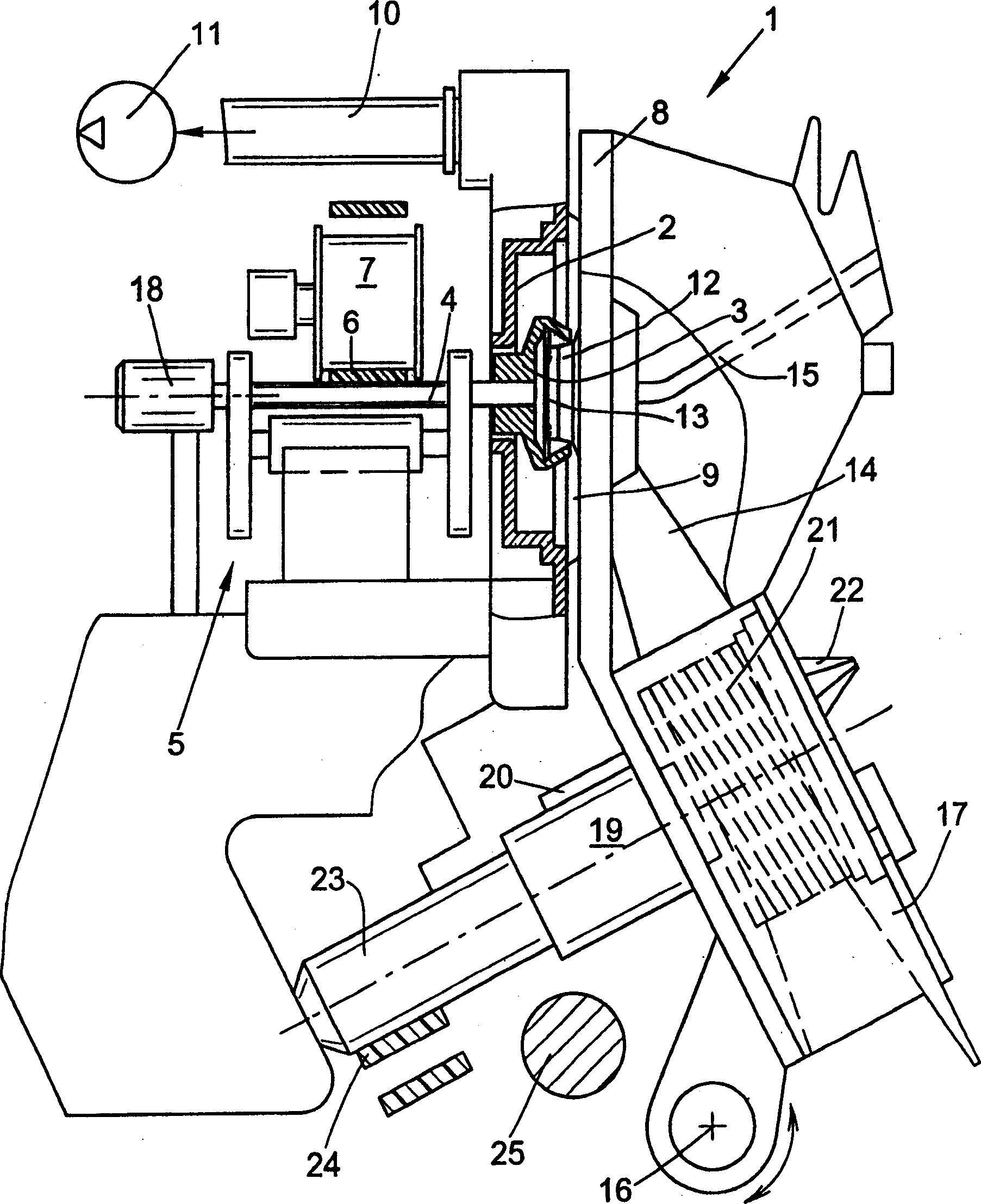

[0061] exist figure 1 The air spinning device shown schematically in , is designated as a whole by the reference number 1 . Such a spinning device has, as is known, a rotor housing 2 in which the rotor part of a rotor 3 rotates at a relatively high rotational speed.

[0062] The rotor 3 is supported with its rotor shaft 4 in the bearing wedge of a washer bearing 5 and is driven by a machine-length tangential drive belt 6 which is loaded by means of a pressure roller 7 . The axial fixation of the rotor shaft 4 takes place, for example, via a permanent-magnetic thrust bearing 18 .

[0063] The rotor housing 2 which is open towards the front can be closed during spinning by a pivotably mounted cover element 8 .

[0064] That is to say, a channel disk opens into the cover element, which channel disk bears against the rotor housing 2 with a lip seal 9 .

[0065] Furthermore, the rotor housing 2 is connected via a corresponding suction line 10 to a low pressure source 11 which ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com