Preparation method of PBAT short fiber

A technology of short fiber and masterbatch, applied in the field of biodegradable fiber materials, can solve the problems of fiber adhesion, difficult continuous and stable forming, etc., and achieve the effect of improving crystallization speed, improving spinnability, and optimizing process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

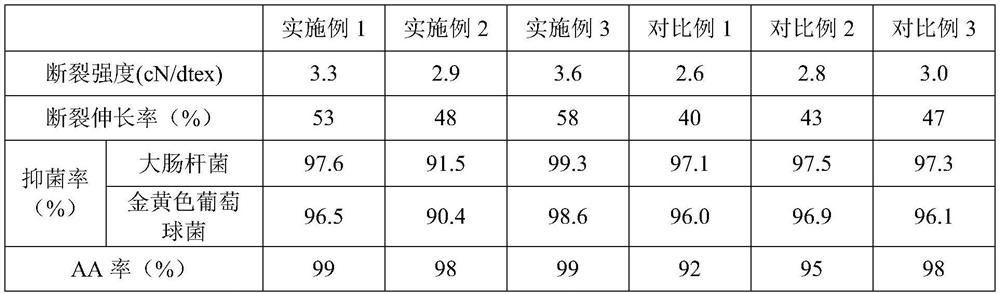

Examples

preparation example Construction

[0034] A preparation method of PBAT staple fiber, comprising the steps:

[0035] (1) Preparation of antibacterial PBAT masterbatch: the PBAT masterbatch and the antibacterial agent are mixed uniformly in a mass ratio of 97~100:0.3~3, and the antibacterial PBAT masterbatch is obtained after melt extrusion, water cooling and pelletizing through a twin-screw extruder, The temperature of each zone of the twin-screw extruder is:

[0036] Each area of the screw temperature(℃) a district 100-150 Second District 160-210 Third District 180-240 Four districts 180-240 District 5 180-240 District VI 180-240 District Seven 180-240 eight districts 180-240 nine districts 180-240 District 10 180-240 die 180-240

[0037] (2) Drying of raw materials: After drying PBAT masterbatch and antibacterial PBAT masterbatch at 65-75°C for 3-5 hours, they are used as core material and skin material respectively;

[0038] (...

Embodiment 1

[0048] A preparation method of PBAT staple fiber, comprising the steps:

[0049] (1) Preparation of antibacterial PBAT masterbatch: Mix the PBAT masterbatch and the antibacterial agent uniformly at a mass ratio of 98:1, melt extrusion, water cooling, and pelletize through a twin-screw extruder to obtain an antibacterial PBAT masterbatch, and twin-screw extrusion. The temperature of each zone of the machine is: 120°C for the first zone, 180°C for the second zone, 220°C for the third zone, 220°C for the fourth zone, 220°C for the fifth zone, 220°C for the sixth zone, 220°C for the seventh zone, 220°C for the eighth zone, and 220°C for the ninth zone. Ten zone 220℃, die head 220℃;

[0050] (2) Drying of raw materials: After drying the PBAT masterbatch and the antibacterial PBAT masterbatch at 70°C for 4 hours, they were used as the core layer material and the skin layer material respectively;

[0051] (3) Pre-spinning: After the core layer material and the skin layer material ar...

Embodiment 2

[0058] A preparation method of PBAT staple fiber, comprising the steps:

[0059] (1) Preparation of antibacterial PBAT masterbatch: Mix the PBAT masterbatch and the antibacterial agent uniformly at a mass ratio of 97:0.3, melt extrusion, water cooling and pelletizing through a twin-screw extruder to obtain an antibacterial PBAT masterbatch, and twin-screw extrusion The temperature of each zone of the machine is: 100°C in the first zone, 160°C in the second zone, 180°C in the third zone, 200°C in the fourth zone, 200°C in the fifth zone, 200°C in the sixth zone, 200°C in the seventh zone, 220°C in the eighth zone, and 220°C in the ninth zone. Ten zone 220℃, die head 220℃;

[0060] (2) Drying of raw materials: After drying the PBAT masterbatch and the antibacterial PBAT masterbatch at 65°C for 5 hours, they were used as the core layer material and the skin layer material respectively;

[0061] (3) Pre-spinning: After the core layer material and the skin layer material are melte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com