Valve assembly for hermetic compressor

A compressor and hermetic technology, applied in variable capacity pump parts, liquid variable capacity machines, pump components, etc., can solve the problems of difficult precise operation of discharge valves, reduced discharge efficiency, complex structure of valve components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, a valve assembly for a hermetic compressor according to the present invention will be described in detail with reference to the accompanying drawings.

[0046] While the present invention is capable of many embodiments, preferred embodiments are described below.

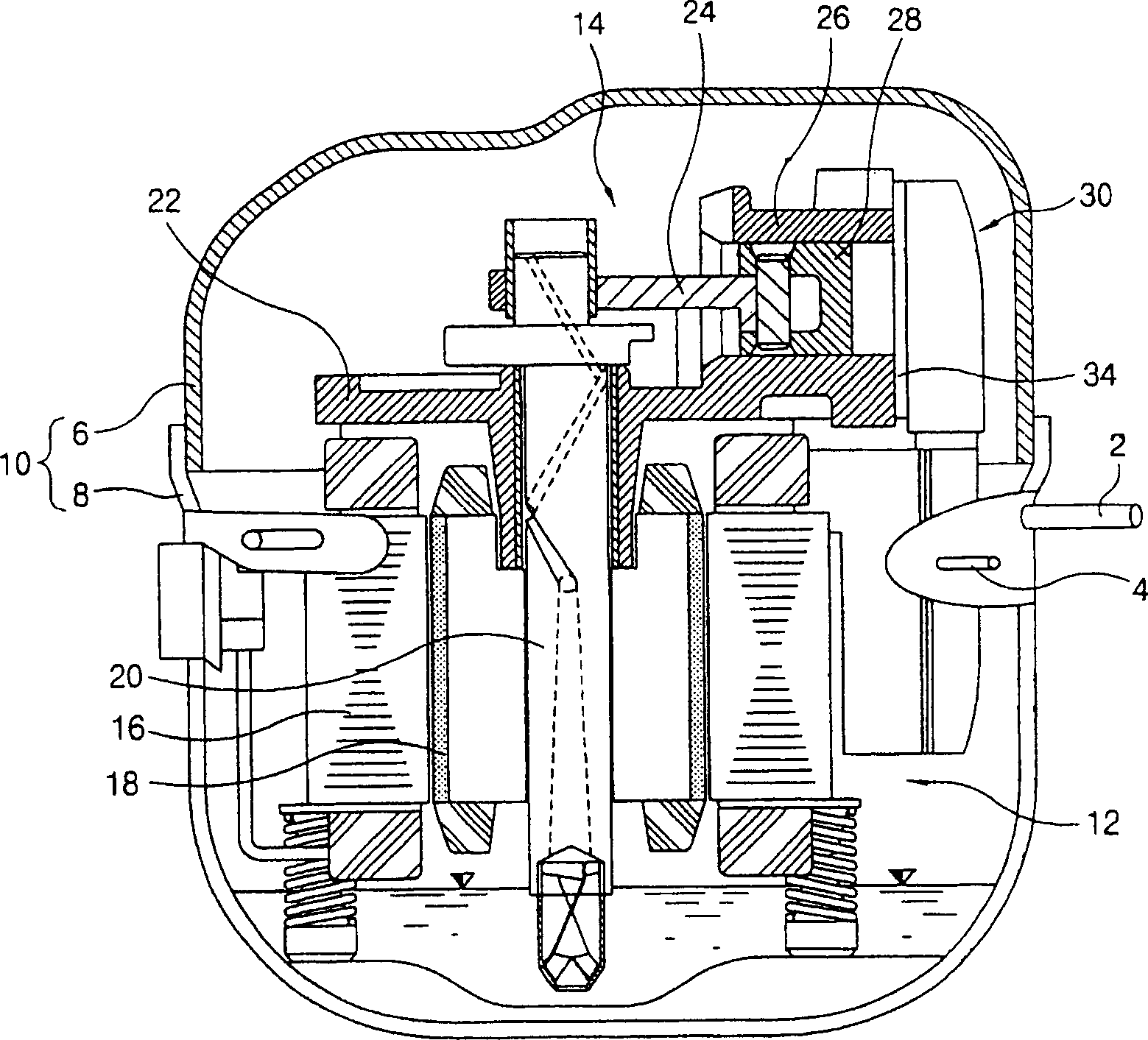

[0047] figure 1 is a cross-sectional view showing a hermetic compressor according to the present invention.

[0048] The hermetic compressor according to the present invention includes: a closed casing 10, where the suction pipe 2 and the discharge pipe 4 are respectively connected; a driving part 12, which is installed in a lower part of the casing 10, and generates rotational force; and a compression part 14 , which is arranged at the upper portion of the casing 10 , compresses the fluid sucked into the suction pipe 2 and discharges the fluid to the discharge pipe 4 using the rotational force generated by the driving part 12 .

[0049] In the case 10, the upper case 6 and the lower case 8 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com