Gas combustion stove

A gas stove and gas technology, applied in the field of brackets, can solve the problems of black smoke and carbon monoxide heat loss, large heat load, small heat load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

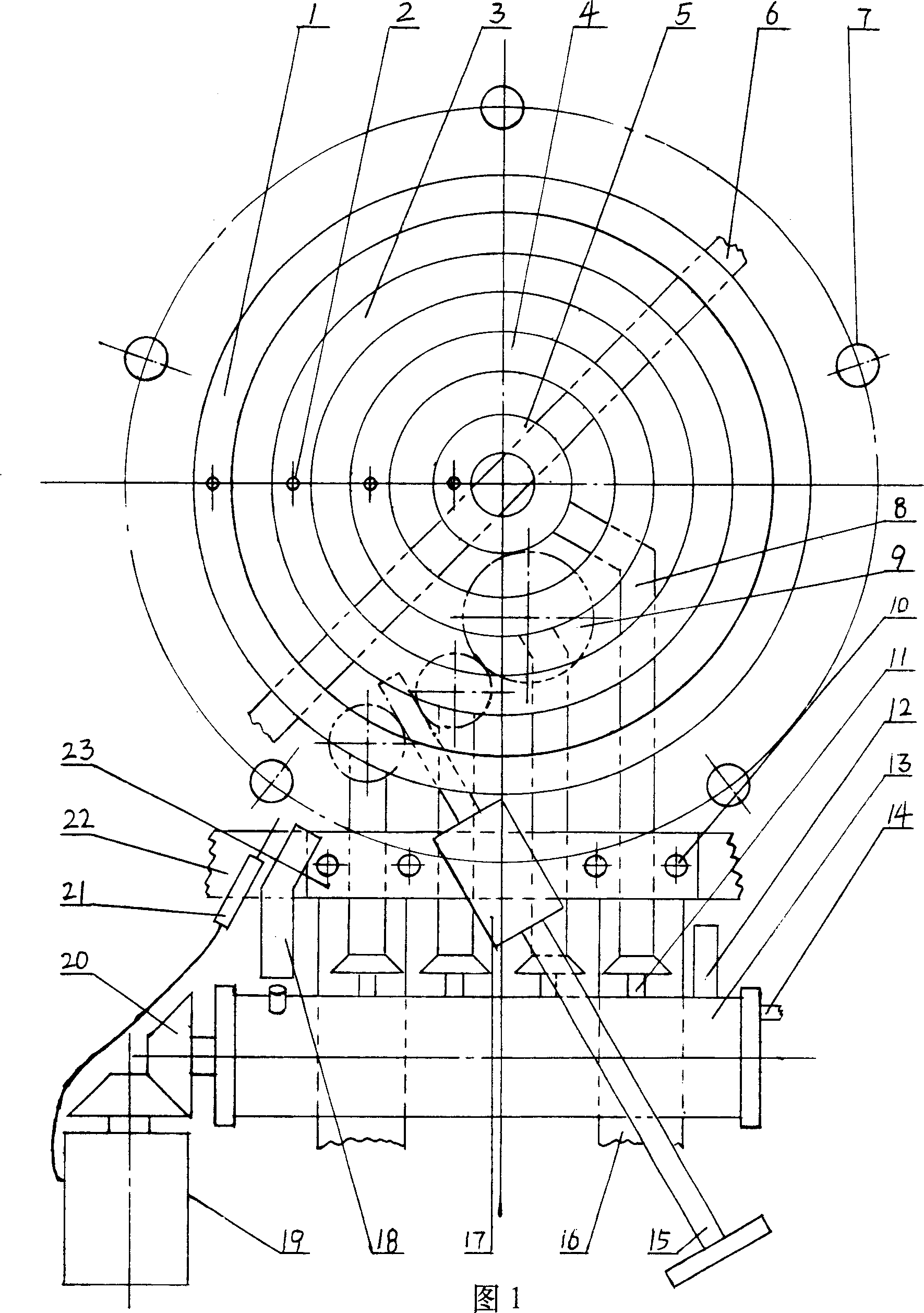

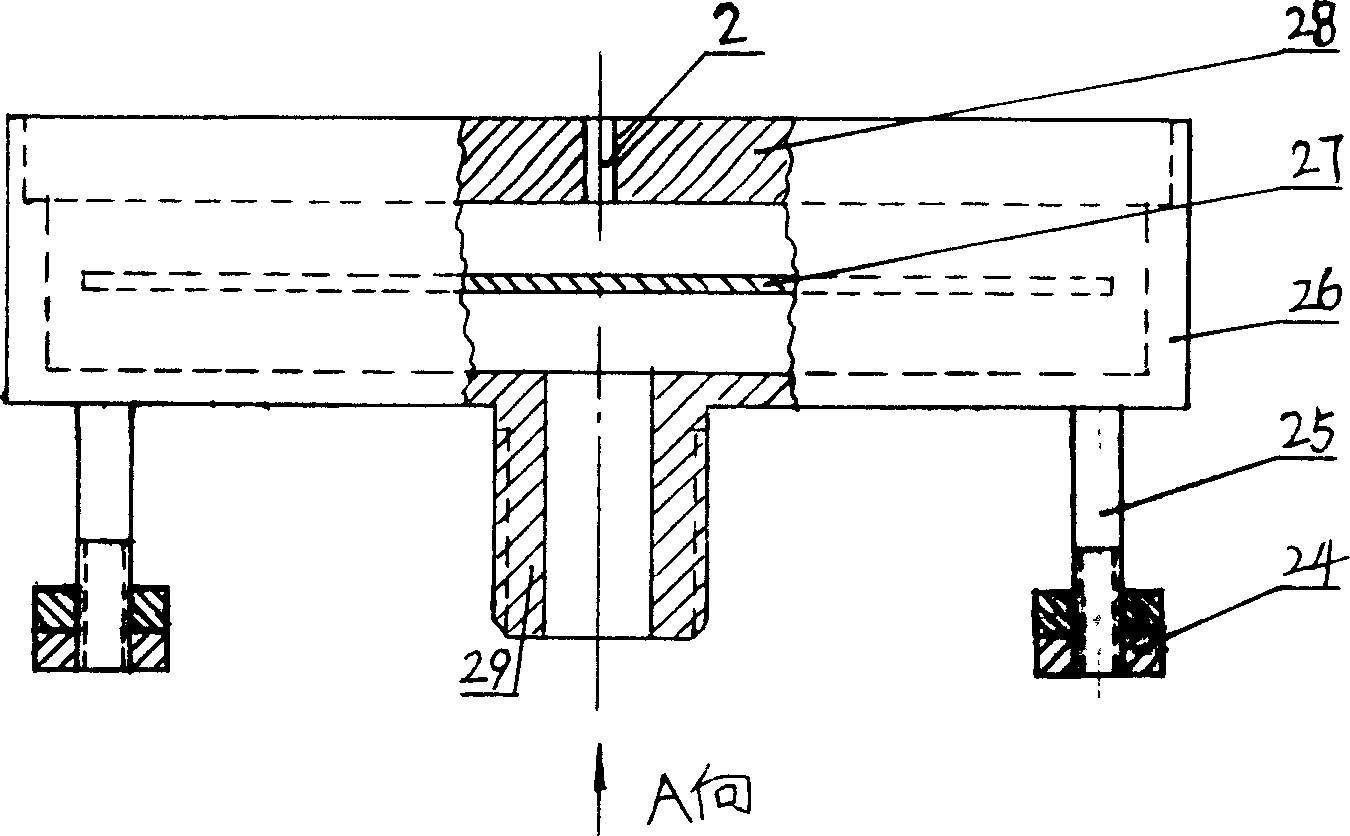

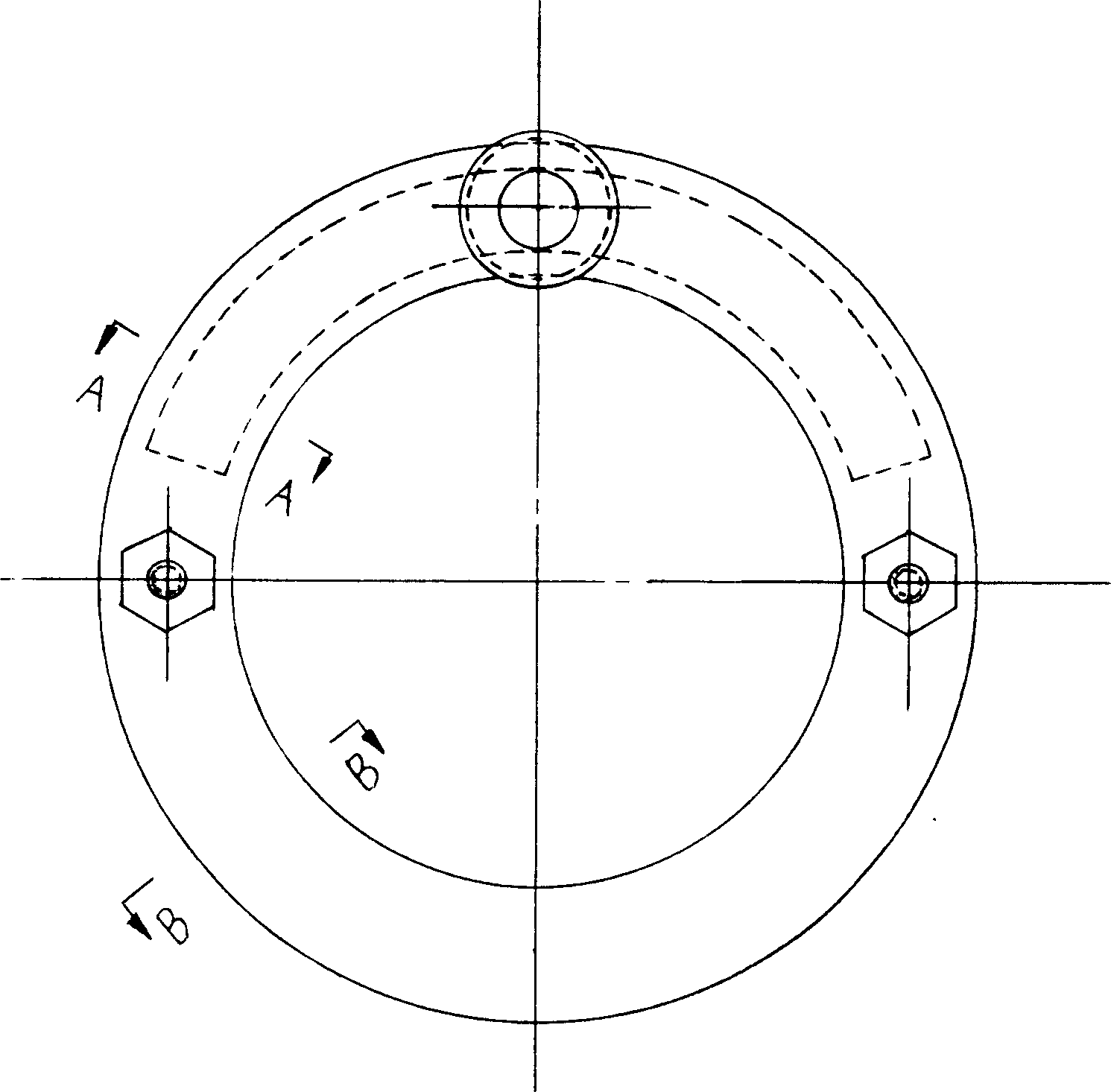

[0081] Described in Fig. 1 is the overall structure diagram of the important components of the gas stove. In the figure, there are several fire holes on each circle of the burning head, and the diameter of the fire holes is about 1.5-3mm. The thicker the fire hole circle, the larger the fire hole diameter. Among the four burners, the first to third circle burners can move up and down, that is, twisting the worm 15 can drive the adjustment sleeve with helical gear or worm gear connected with the first circle burner 1 and the second circle burner 3 to rotate , to push the intake pipe matched with the internal thread of the adjustment sleeve to rise or fall, thereby pushing the burner to move up or down. For the working principle of the up and down movement, see Figure 10 to Figure 11 . When the worm rotates, the helical gear that links to each other with the second circle burner directly drives the third helical gear to rotate. The pitch of the internal thread of the adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com